What printer can print on Acrylic?

How Uv Flatbed Printers Work on Acrylic

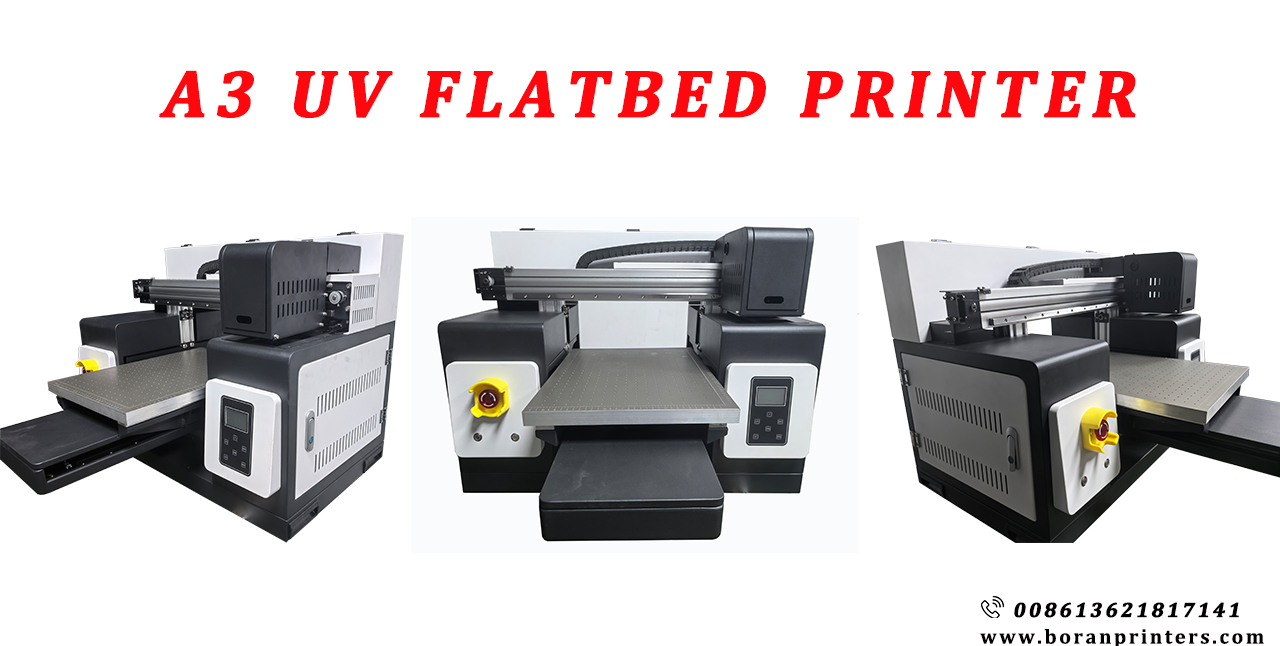

UV flatbed printers utilize a digital inkjet process combined with ultraviolet (UV) light. Here's a breakdown of how it works:

1.Preparation: First, the acrylic sheet is placed onto a flat bed within the printer. A clean surface is crucial for proper ink adhesion, so the acrylic is often cleaned to remove any dust, oils, or static.

2.Ink Deposition: The printer's print heads precisely jet microscopic droplets of specialized UV-curable ink directly onto the acrylic surface. These inks contain photoinitiators, which are chemicals designed to react to UV light.

3.Instant Curing: Immediately following the ink deposition, integrated UV LED lamps, situated alongside the print heads, emit ultraviolet light. This UV light instantly "cures" or hardens the ink. This rapid curing prevents the ink from spreading or bleeding, resulting in incredibly sharp, vibrant images with fine detail.

4.Layering for Special Effects (Optional): For enhanced opacity, especially on clear acrylic, or to create tactile effects like raised textures, the printer can apply multiple layers of ink. A common technique for clear acrylic is the "sandwich" method (sometimes called the "Oreo cookie technique"), where color is printed, then a white ink layer is added behind it, and sometimes another color layer. This ensures vivid colors when viewed from the front, even if the back of the acrylic is visible.

Key Benefits of UV Printing on Acrylic

UV printing offers numerous advantages that make it the preferred method for printing on acrylic:

1.Vibrant, High-Quality Prints:Uv Inks produce exceptionally bright, rich, and high-resolution images. The instant curing prevents dot gain, ensuring sharp lines and accurate color reproduction.

2.Durability and Longevity: Once cured, UV inks form a strong, permanent bond with the acrylic surface. This makes the prints highly resistant to scratching, fading, moisture, and general wear and tear, even in outdoor environments. Acrylic itself is a durable, UV-resistant material, and the UV-cured inks enhance this longevity.

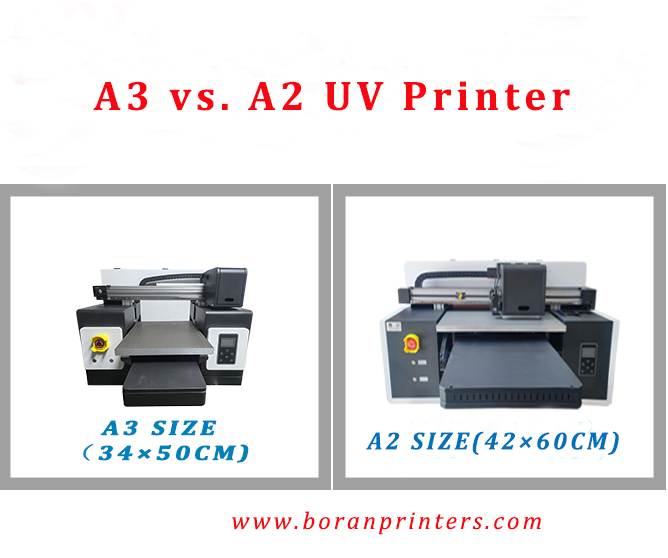

3.Versatility: UV flatbed printers can handle a wide range of acrylic thicknesses, from thin sheets to thick blocks. They can print on various types of acrylic, including clear, colored, frosted, and even black acrylic, with consistent results.

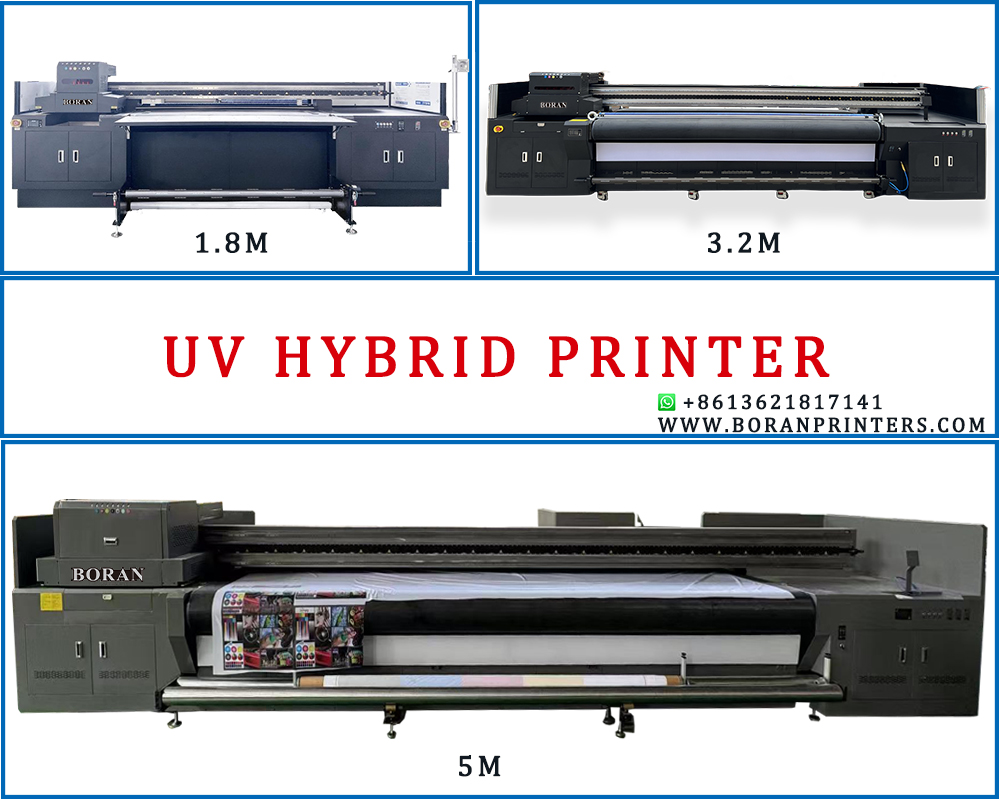

4.Fast Production: The instant drying of UV inks eliminates the need for drying time between color passes or before handling the printed piece. This significantly speeds up production and allows for faster turnaround times.

5.Direct-to-Substrate Printing: Unlike traditional methods that might require transferring an image from paper or film, UV printers apply ink directly to the acrylic. This simplifies the process and reduces potential for errors or inconsistencies.

6.Special Effects: UV printers can achieve unique effects such as raised text, textured surfaces, and even 3D illusions by layering clear ink or multiple color passes. This opens up creative possibilities for signage, displays, and artistic applications.

7.Environmental Friendliness: UV inks are generally more environmentally friendly than solvent-based inks because they don't contain volatile organic compounds (VOCs) that evaporate into the air.

Other Printing Methods for Acrylic

While UV printing is the dominant and most effective method, other techniques can be used to print on acrylic, each with its own advantages and limitations:

1.Screen Printing: This traditional method involves pushing ink through a mesh screen (stencil) onto the acrylic surface. Each color requires a separate screen, making it suitable for large runs of simple, solid-color designs. It offers excellent opacity and durability. However, it's less ideal for complex, multi-color images, photographic prints, or small batch customization due to the extensive setup time and cost.

2.Inkjet Printing (with specialized inks/pre-treatment): Some standard inkjet printers, when equipped with specialized inks and potentially requiring pre-treatment or coatings on the acrylic surface to aid adhesion, can print on acrylic. However, the results typically won't match the durability, vibrancy, or instant curing of a dedicated UV printer. The ink may take longer to dry and might be more prone to scratching or fading.

3.Vinyl Application (indirect method): While not directly "printing" on acrylic, vinyl graphics are a very common way to add designs. An image is printed onto adhesive vinyl, which is then applied to the acrylic sheet. This offers good color vibrancy and durability, but it's a separate process and the vinyl can sometimes peel or bubble over time, especially with exposure to the elements.

4.Face Mounting (photo paper onto acrylic): This method involves printing an image on high-quality photo paper and then adhering it to the back surface of the acrylic using a special adhesive or laminating film. The image is viewed through the acrylic, giving it depth and protection. While it can produce stunning photographic results, it's not direct printing and is primarily used for fine art prints or photographic displays.

Conclusion

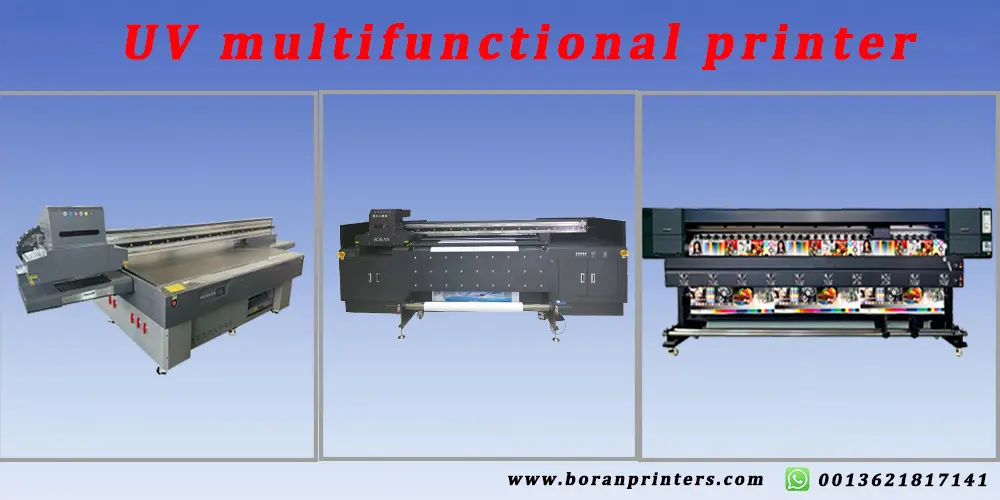

For most professional applications requiring high-quality, durable, and vibrant prints on acrylic, a UV flatbed printer is the superior choice. Its ability to directly print and instantly cure inks results in a robust and visually appealing product, making it indispensable for signage, displays, decorative panels, and custom acrylic items. While other methods exist, they often come with limitations in terms of image quality, durability, or versatility compared to UV printing technology.

If there is any need about UV flatbed printer for your Acrylic, please visit our website: https://site_7ba8f8cb-fff6-4782-b92e-dd7c504e45dc/large-format-industrial-2513-uv-led-flatbed-printer-with-ai-scanner-camera-product/

And more details, feel free to WhatsApp: 008613621817141.

JIAXING BORAN DIGITAL TECHNOLOGY CO.,LTD