what is uv multifunctional printer?

How UV Curing Technology Works

The magic of a UV printer is in its unique ink and curing process. Unlike traditional inks that dry through heat or solvent evaporation, Uv Printers use a special type of ink filled withphotoinitiators. The printing process is as follows:

1.Ink Jetting: The printer head precisely jets tiny droplets of this UV-curable ink onto the surface of an object, also known as the substrate.

2.Instant Curing: Immediately following the ink deposition, a powerful UV-LED lampon the print head emits ultraviolet light. This light instantly triggers a chemical reaction, causing the ink to solidify or "cure" in a matter of seconds.

3.This instantaneous curing is the key difference. It prevents the ink from spreading or bleeding, resulting in exceptionally sharp, high-resolution images. Because the ink is hardened into a solid layer on the surface, there's no drying time needed, making the entire production process significantly faster and more efficient.

The "Multifunctional" Advantage

The term "multifunctional" in a UV printer context refers to its versatile capabilities that enable a wide range of applications:

1.Material Versatility: This is arguably the most significant advantage. A UV printer can print on virtually any flat or slightly curved surface. This includes traditional materials like paper and cardboard, but also extends to rigid and non-porous substrates such as wood, metal, glass, plastic, ceramic, leather, and acrylic. This ability opens up a world of possibilities for product customization and manufacturing that was previously limited.

2.Diverse Print Effects: Beyond standard full-color printing (using CMYK inks), many UV printers come equipped with additional ink channels for special effects:

3.White Ink: Essential for printing on dark or transparent materials. The white ink is printed first as a base layer, allowing the colors on top to appear vibrant and true to their original design.

4.Varnish/Clear Coat: This transparent ink can be used to create glossy or matte finishes on specific parts of a design. It adds a premium, tactile feel and enhances the visual impact of the final product.

5.Embossing (3D Texture): By layering the ink multiple times, a UV printer can create raised, textured prints. This is perfect for simulating a carved effect on wood, creating a tactile design on a phone case, or adding a luxurious feel to an art print.

6.Integrated Workflow: Many modern UV printers are not just printing machines. They are often integrated with software that manages the entire workflow, from file preparation to color management. Some devices also include built-in scanners and copiers, further streamlining the production process for businesses.

Key Advantages over Traditional Printers

When compared to conventional printing methods, UV multifunctional printers offer a host of compelling benefits:

1.Superior Durability: The cured Uv Ink forms a hard, robust layer that is highly resistant to scratches, fading from UV exposure, water damage, and chemical abrasions. This makes UV prints ideal for outdoor signage, industrial labels, and frequently handled items like promotional products.

2.Eco-Friendliness: UV inks contain little to no volatile organic compounds (VOCs), which are harmful to both the environment and human health. This makes the UV printing process a much cleaner and safer alternative to solvent-based printing methods.

3.Faster Production Times: Because the ink cures instantly, there is no need to wait for prints to dry. This drastically reduces production turnaround times, making it perfect for urgent orders and high-volume manufacturing.

4.Cost-Effectiveness for Short Runs: For customized or low-volume orders, UV printing is often more cost-effective than traditional methods like screen printing, which require significant setup time and material for each new design. UV printing is a direct-to-object process, so you can print a single item just as easily as a hundred, with no extra setup costs.

Common Types and Applications

UV printers come in a few main forms, each suited for different applications:

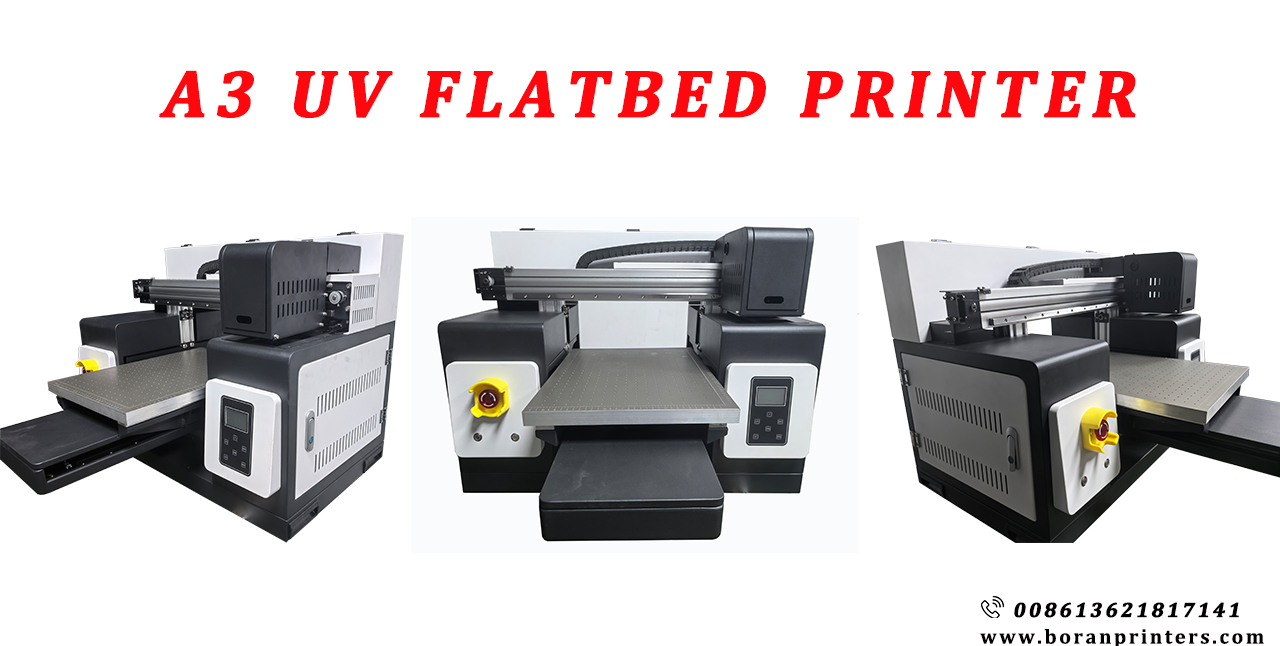

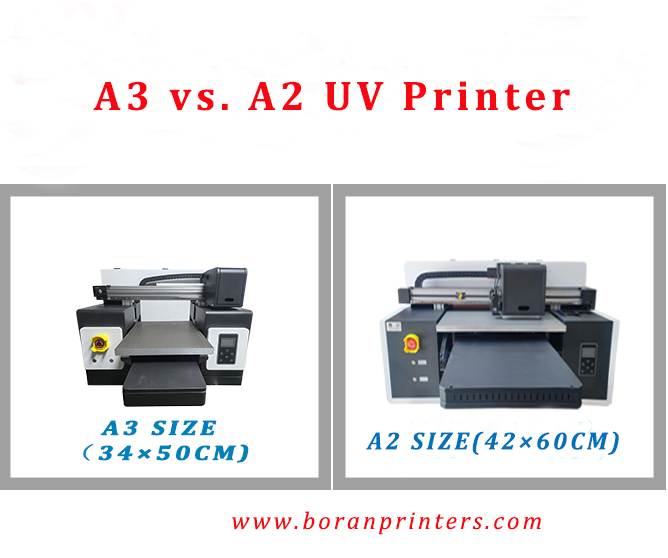

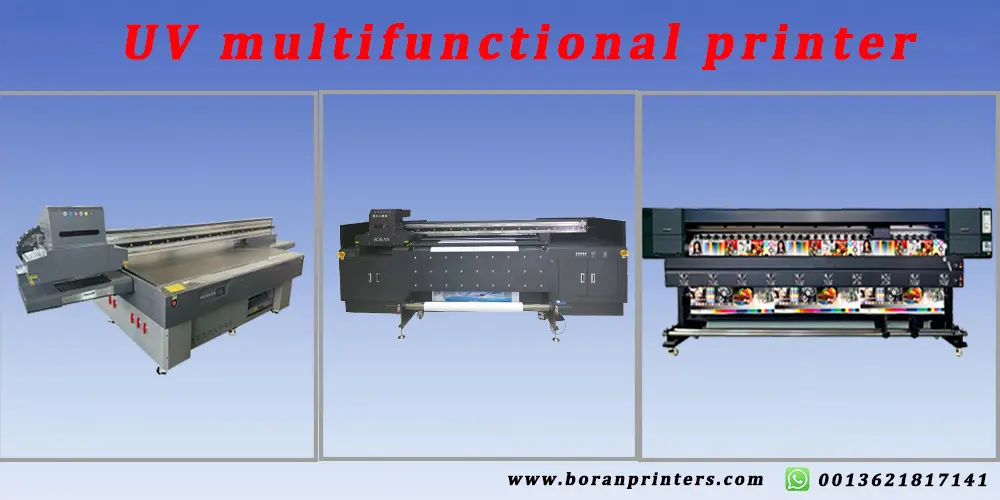

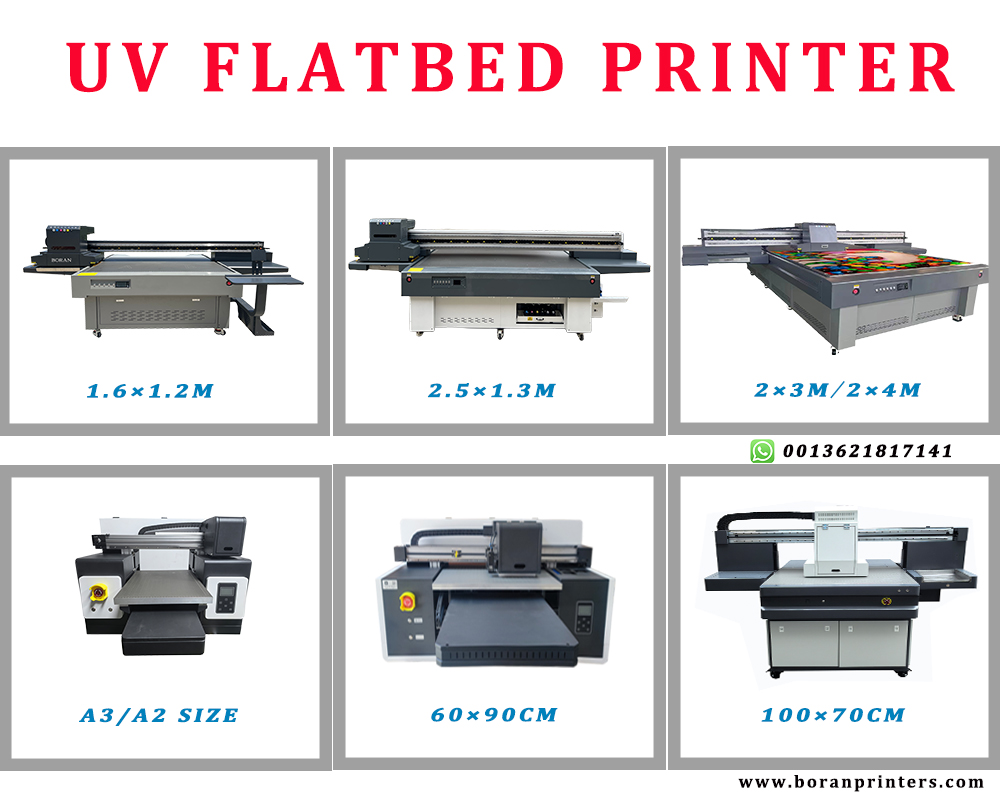

1.UV Flatbed Printers: These have a large, flat bed where you place rigid materials (like a wooden plaque or a metal panel) for printing. They are the most common type and are used for custom signage, phone cases, awards, and personalized home decor.

2.UV Roll-to-Roll Printers: Designed for flexible, roll-based media like vinyl, banners, and wallpaper. They are essential for creating large-format graphics and commercial signage.

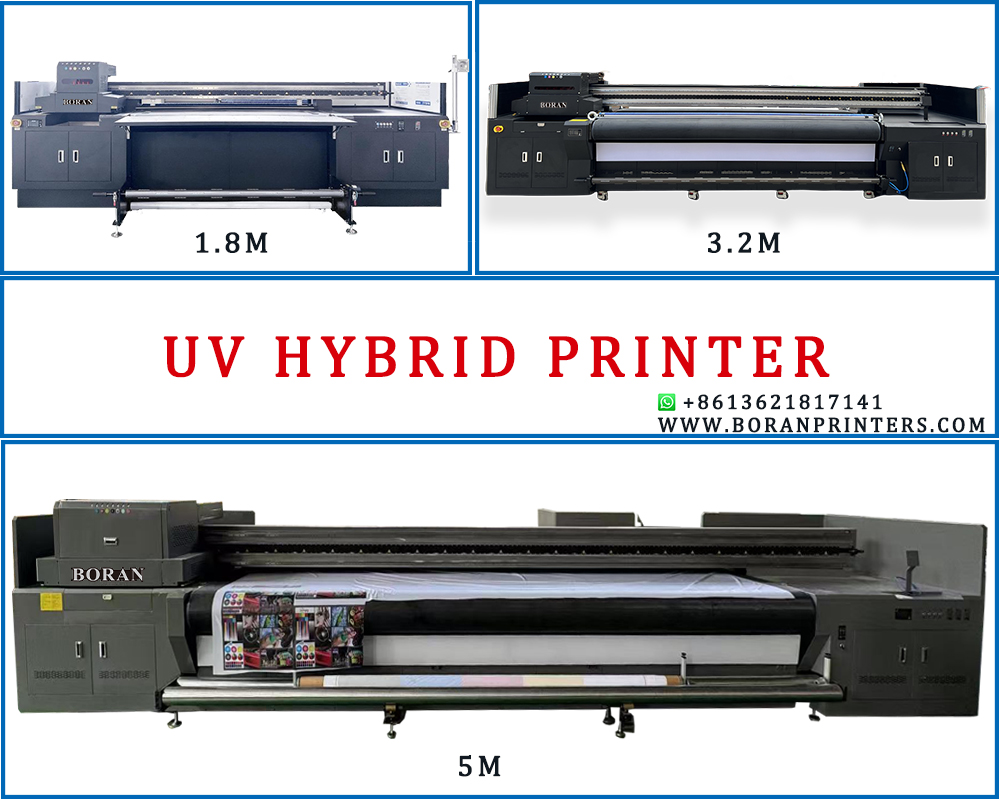

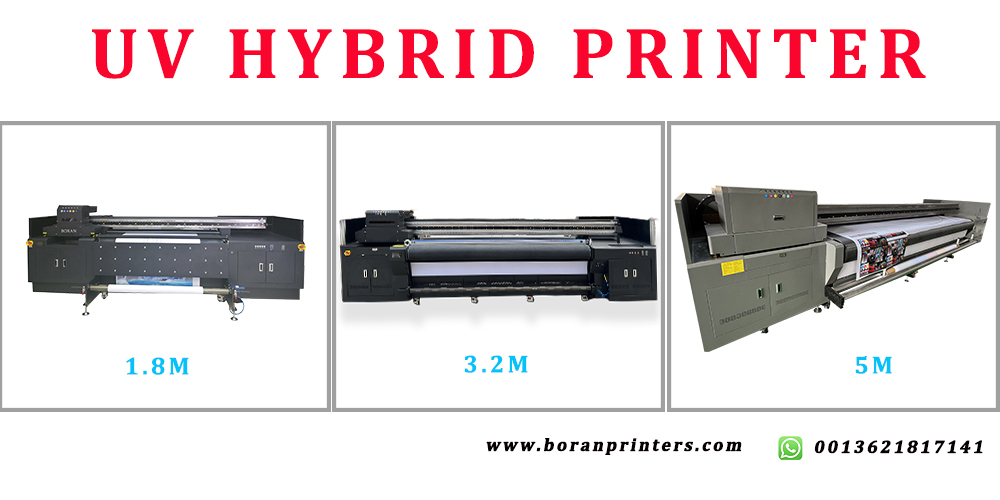

3.UV Hybrid Printers: These combine the features of both flatbed and roll-to-roll printers, offering maximum versatility to print on both rigid boards and flexible rolls.

In conclusion, a UV multifunctional printer is a transformative technology that has redefined the possibilities of digital printing. By leveraging UV light to instantly cure ink, it provides a versatile, durable, and efficient solution for printing high-quality, long-lasting designs on an extensive range of materials. It has become an indispensable tool for businesses in signage, promotional products, interior design, and industrial manufacturing, unlocking new levels of customization and creativity.

JIAXING BORAN DIGITAL TECHNOLOGY CO.,LTD

site_7ba8f8cb-fff6-4782-b92e-dd7c504e45dc