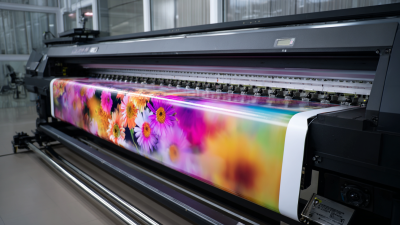

In today's rapidly evolving printing landscape, the emergence of the UV flatbed printer A3 has revolutionized the way creative professionals approach their projects. With advanced technology that allows for vibrant color reproduction and versatility across various substrates, this printer type has gained significant traction in industries such as signage, packaging, and custom decor. According to the Smithers Pira report, the global digital printing market is projected to reach $31.7 billion by 2024, with UV printing technologies playing a pivotal role in this growth. The UV flatbed printer A3 not only enhances production efficiency but also expands the boundaries of design possibilities, making it an indispensable tool for artists and businesses alike. As we delve deeper into this guide, we will explore the capabilities, applications, and advantages of the UV flatbed printer A3, unlocking new realms of creativity in modern printing.

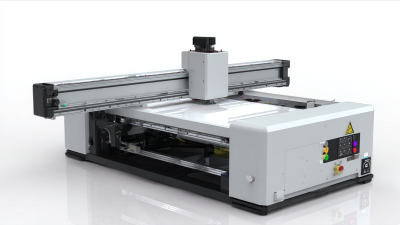

The A3 UV flatbed printer has revolutionized the printing landscape with its versatility and efficiency. These printers utilize ultraviolet light to cure or dry the ink as it is printed, allowing for high-quality, vibrant prints on a variety of materials including wood, glass, and metal. According to a recent report by Smithers Pira, the global market for digital printing is anticipated to reach $32.4 billion by 2024, reflecting a growing demand for technologies that can produce custom and innovative products rapidly.

One of the key features of A3 UV flatbed printers is their ability to print directly onto objects, thus eliminating the need for labels or other types of transfers. This not only streamlines production processes but also enhances the durability of prints. Additionally, these printers often come equipped with advanced software that simplifies design adjustments, making it easier for users to achieve desired effects with minimum effort.

**Tips**: When investing in an A3 UV flatbed printer, consider one with adjustable height capabilities to accommodate varying material thicknesses. Also, ensure that the printer has a quick-drying feature which can significantly reduce turnaround time. Lastly, always opt for a model that offers a range of ink types to ensure compatibility with diverse substrates.

In the realm of modern design, UV printing has sparked a revolution that redefines creative possibilities. As per a report by Smithers Pira, the global UV printing market is projected to reach $25.5 billion by 2025, showcasing a compound annual growth rate (CAGR) of 12%. This surge is largely attributed to the versatility of UV flatbed printers, which allow designers to print on a wide variety of substrates, including wood, glass, metal, and even textiles, thereby expanding the horizons of design innovation.

The capabilities of A3 UV flatbed printers further enhance creative applications, enabling artists and businesses alike to produce intricate designs with exceptional detail and color vibrancy. A case in point is their use in creating bespoke promotional items and personalized gifts, which are increasingly popular in the consumer market. According to Statista, the demand for personalized products is expected to grow by 20% annually, reflecting an undeniable trend where uniqueness and creativity drive consumer purchasing decisions. As artists harness the power of UV printing, they can transform ideas into tangible art pieces, redefining the landscape of creativity and design in the printing industry.

In the realm of modern printing, A3 UV flatbed printers represent a pivotal evolution, offering capabilities that traditional methods often cannot match. These printers utilize ultraviolet light to cure ink instantly, which not only enhances speed and efficiency but also allows for high-quality prints on a wide variety of surfaces. The cost-effectiveness of A3 UV flatbed printers becomes particularly evident when examining their operational longevity and flexibility. Businesses can save on material costs while increasing production capabilities, making these printers a rewarding investment for those seeking innovation in their printing processes.

In the realm of modern printing, A3 UV flatbed printers represent a pivotal evolution, offering capabilities that traditional methods often cannot match. These printers utilize ultraviolet light to cure ink instantly, which not only enhances speed and efficiency but also allows for high-quality prints on a wide variety of surfaces. The cost-effectiveness of A3 UV flatbed printers becomes particularly evident when examining their operational longevity and flexibility. Businesses can save on material costs while increasing production capabilities, making these printers a rewarding investment for those seeking innovation in their printing processes.

Moreover, as we shift towards rapid diagnostic tools in healthcare, the principles behind A3 UV flatbed printing can be seen as analogous to advancements in medical technologies. Just as electrophoretic techniques are being developed for rapid detection of bacterial pneumonia—a pressing global health issue—A3 UV flatbed printers provide a swift and adaptable solution for various printing needs. In both fields, the focus is on improving efficiency and accuracy, showcasing how modern techniques can transform traditional frameworks, ultimately leading to better outcomes and enhanced service delivery.

The advent of UV flatbed printers, especially the A3 models, has revolutionized the printing industry by enhancing creativity and productivity. To maximize efficiency in A3 UV print production, it’s essential to adopt several key strategies. First, choosing the right materials is crucial. Using high-quality substrates tailored for UV printing can significantly improve adhesion and reduce production hiccups.

Another vital tip involves optimizing printer settings. Regularly calibrate your printer to ensure accurate color representation and consistent output. Adjusting settings such as ink density can dramatically impact the vibrancy of your prints. Furthermore, maintaining your printer through routine cleaning and servicing helps avoid downtime and preserves print quality.

Lastly, effective workflow management plays a pivotal role in maximizing production efficiency. Implementing a streamlined process for design approval, print setup, and batch processing can save valuable time. Utilizing software that integrates design and print functions also minimizes errors and enhances overall productivity, allowing businesses to meet tighter deadlines without compromising on quality.

The UV printing market is poised for significant growth in the coming years, driven by advances in technology and an increasing demand for high-quality print solutions. According to a report by Smithers Pira, the global UV printing market is expected to reach $18.2 billion by 2025, growing at a CAGR of 9.4%. This growth is largely attributed to the versatility of UV printing, which accommodates various substrates, including plastics, metals, and textiles, making it ideal for diverse applications ranging from packaging to signage.

As the industry evolves, several trends are emerging that will shape the future of UV printing. The introduction of eco-friendly UV inks and energy-efficient curing systems is gaining traction, reflecting a shift towards sustainability. Additionally, advancements in digital flatbed technology are enhancing print speeds and quality, allowing businesses to cater to the growing demand for customized products.

Tips:

1. Invest in high-quality UV inks to ensure vibrant colors and durability in your prints, which can significantly enhance customer satisfaction.

2. Stay updated on technological trends to leverage new features and improvements in UV flatbed printers, as this can give your business a competitive edge.

3. Consider sustainability in your printing practices by exploring eco-friendly inks and materials, as consumers increasingly favor environmentally responsible products.