The world of printing is rapidly evolving, especially with the rise of the Large UV Flatbed Printer. As noted by industry expert Dr. Janet Lee, “These printers unlock new possibilities in design and creativity.” Understanding the capabilities and models available in this market is crucial for businesses looking to enhance their offerings.

Large UV Flatbed Printers are known for their versatility and ability to print on various materials. They are transforming how graphics, signage, and packaging are produced. This technology allows for vibrant imagery and incredible detail. Yet, there remains a steep learning curve. Many companies struggle to leverage the full potential of these machines.

Choosing the right model can be daunting. Each printer varies in features and specifications. A careful selection can lead to significant improvements in efficiency. It's important to weigh the options and understand the specific needs of your business. Ignoring these factors could lead to less-than-ideal investment decisions. The impact of a Large UV Flatbed Printer reaches beyond mere printing; it influences market competitiveness.

When choosing a large UV flatbed printer, several features stand out as critical. One of the most important aspects is print quality. High-resolution capabilities ensure vibrant colors and sharp details. The ability to print on various materials enhances versatility. A printer that handles wood, glass, and metal expands design possibilities.

Speed is another key consideration. Businesses often demand quick turnaround times. Some printers offer impressive speeds but may compromise on quality. This balance requires careful evaluation. Look for a printer that delivers quality at a reasonable pace.

Next, consider the software compatibility. A user-friendly interface makes a significant difference. Complex software can frustrate operators and hinder production efficiency. Additionally, robust customer support is essential. You may face unexpected challenges or need assistance with maintenance. Reliable support can save time and reduce downtime. As you weigh your options, reflect on these details to find the right printer for your needs.

When exploring large UV flatbed printers, several key factors come into play. Size, print quality, and speed are essential. Each model has its strengths and weaknesses. It's crucial to evaluate what fits specific needs best. Some printers shine in speed but may compromise on detail. Others excel in vibrant color output but may fall short in volume production.

User experiences can vary widely. A model may have excellent reviews in detail but face reliability issues in prolonged use. It's important to dig deeper. Read multiple sources and consider real-world feedback. Often, the most talked-about options might not suit every business's workflow or budget.

Cost also plays a significant role. While some printers offer great technology, their price point can be prohibitive. Budget constraints can limit choices considerably. It’s important to weigh initial investment against long-term efficiency. Balancing quality and cost can be tricky. Preferences can change, and features might evolve. Keeping an eye on market trends helps navigate this dynamic landscape.

| Model | Printing Area (mm) | Max Media Thickness (mm) | Print Speed (m²/h) | Resolution (dpi) | Ink Type | Price (USD) |

|---|---|---|---|---|---|---|

| Model A | 2500 x 1300 | 50 | 45 | 1200 | UV Curable | 35,000 |

| Model B | 3000 x 2000 | 60 | 50 | 1440 | UV Curable | 50,000 |

| Model C | 2500 x 1500 | 70 | 30 | 720 | LED UV | 28,000 |

| Model D | 2800 x 1700 | 80 | 60 | 1200 | Eco-Solvent | 40,000 |

| Model E | 3200 x 2000 | 75 | 55 | 1800 | UV Curable | 68,000 |

| Model F | 2500 x 2500 | 90 | 40 | 1200 | UV Curable | 30,000 |

| Model G | 2800 x 1600 | 65 | 35 | 720 | LED UV | 26,000 |

| Model H | 3000 x 1500 | 55 | 50 | 1440 | UV Curable | 38,000 |

| Model I | 2700 x 1600 | 80 | 70 | 1200 | Eco-Solvent | 55,000 |

| Model J | 3200 x 2400 | 60 | 65 | 1800 | UV Curable | 70,000 |

Large UV flatbed printers are revolutionizing industries by enabling high-quality printing on various substrates. Their flexibility makes them ideal for signage, packaging, and interior decor. According to a recent industry report, the global market for UV printers is projected to grow significantly, driven by increased demand for custom printing solutions.

These printers can handle diverse materials like wood, metal, glass, and plastic. This versatility allows businesses to expand their service offerings. Users can create stunning visuals with precision. UV flatbed printers also cure inks instantly, reducing production time. This efficiency translates to faster project turnaround. A decrease in waste is also a key advantage, as the curing process minimizes ink spillage.

Tips: Always test on sample materials to ensure compatibility. Monitor the printer settings regularly to avoid quality loss. Maintain cleanliness to keep equipment running smoothly.

Despite these advantages, some users face challenges. Initial setup can be complex, and proper training is crucial. The cost of maintenance and inks can be high. Business owners must weigh these factors against potential profits to decide wisely. Investing in a large UV flatbed printer can open new doors, but careful planning is essential.

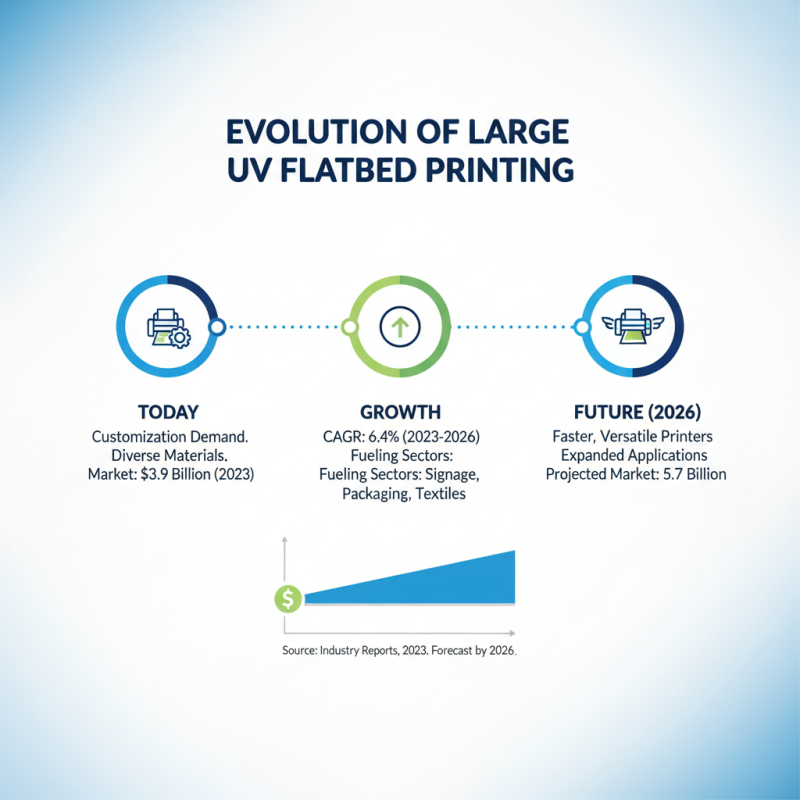

Large UV flatbed printing technology is evolving rapidly. According to industry reports, the market for flatbed printers is projected to reach $5.7 billion by 2026, growing at a CAGR of 6.4%. This growth is fueled by increasing demand for customized printing in various sectors, including signage, packaging, and textiles. As technology advances, printers will become faster and more versatile.

New developments in UV curing inks are notably improving print quality. These inks are now more vibrant and durable than before. They adhere to a variety of substrates, expanding creative possibilities. However, challenges remain. Ink cost is high, which limits some companies from upgrading. There’s also a significant investment in equipment and maintenance.

User training is crucial for maximizing productivity. Some users find it difficult to adapt to new software or construction features. This can lead to underutilization of the printer’s capabilities. Keeping pace with advancements demands ongoing education and practice. It would be beneficial for companies to provide regular training sessions for their staff. The future may hold breakthroughs that make this technology more accessible. But addressing current challenges is essential for widespread adoption.

Maintaining a UV flatbed printer is essential for its longevity and performance. Regular cleaning helps prevent ink buildup, which can affect print quality. Use a lint-free cloth and recommended cleaning solutions. This simple step can make a significant difference in how your printer performs. Neglecting this may lead to clogs and more serious issues.

Adjusting print settings optimally is also crucial. Experiment with different resolutions and speed settings based on the material you're using. Sometimes, a lower resolution can save ink and provide satisfactory results. Additionally, monitor the ink levels frequently. Waiting until empty can damage the print heads.

Finally, conduct routine inspections to catch small problems early. Check for any signs of wear and tear on the printer. Look at the belts, rollers, and other components. Even minor issues can escalate if ignored. Keeping a maintenance log can help track these details. Embracing maintenance is not just about fixing; it’s about prevention and better understanding your equipment.