The printing industry has undergone remarkable transformations over the years, with the emergence of innovative technologies paving the way for enhanced efficiency and creativity. Among these advancements, the UV flatbed printer stands out as a revolutionary tool that has reshaped the landscape of commercial and industrial printing.

According to a recent report by Smithers Pira, the global market for digital printing is projected to reach $187 billion by 2024, fueled by the demand for high-quality, customizable prints.

UV flatbed printers exemplify this trend, offering exceptional versatility by enabling printing on various substrates, from rigid materials like wood and metal to flexible options like fabrics. With capabilities that support both small and large production runs, these printers are gaining traction across various sectors, allowing businesses to meet the evolving demands for rapid turnaround times and unique product offerings.

As we delve deeper into the world of UV flatbed printing, it becomes clear that this technology is not just an accessory but a catalyst driving the future of the printing industry.

The printing industry has undergone remarkable transformations over the years, with the emergence of innovative technologies paving the way for enhanced efficiency and creativity. Among these advancements, the UV flatbed printer stands out as a revolutionary tool that has reshaped the landscape of commercial and industrial printing.

According to a recent report by Smithers Pira, the global market for digital printing is projected to reach $187 billion by 2024, fueled by the demand for high-quality, customizable prints.

UV flatbed printers exemplify this trend, offering exceptional versatility by enabling printing on various substrates, from rigid materials like wood and metal to flexible options like fabrics. With capabilities that support both small and large production runs, these printers are gaining traction across various sectors, allowing businesses to meet the evolving demands for rapid turnaround times and unique product offerings.

As we delve deeper into the world of UV flatbed printing, it becomes clear that this technology is not just an accessory but a catalyst driving the future of the printing industry.

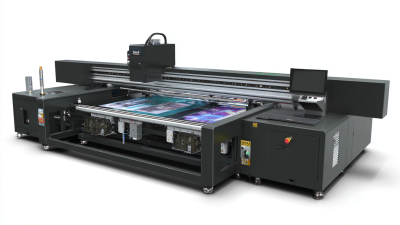

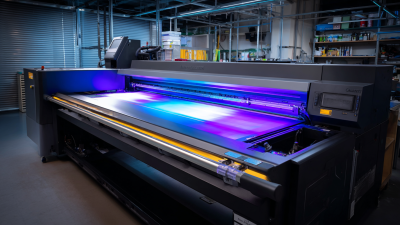

UV flatbed printers have become a game-changer in the printing industry, thanks to their unique features and advantages. Unlike traditional printers that rely on heat and ink absorption, UV flatbed printers use ultraviolet light to instantly cure and dry the ink as it is printed. This technology allows for printing on a wide variety of materials, including glass, wood, metal, and plastics, making it incredibly versatile. The ability to print directly onto rigid substrates opens up new creative possibilities for artists, sign makers, and manufacturers alike.

One of the key benefits of UV flatbed printers is their exceptional print quality. The UV inks produce vibrant colors and sharp details, creating stunning graphics that stand out. Furthermore, these printers are environmentally friendly, as they minimize waste and use inks that are free from harmful solvents. The quick curing process also enhances productivity by reducing drying time, enabling businesses to fulfill orders faster. With their robust capabilities and efficiency, UV flatbed printers are truly revolutionizing how products and promotional materials are produced in the modern printing landscape.

UV flatbed printers are transforming the printing industry by significantly enhancing production speed and efficiency. This innovative technology utilizes ultraviolet light to cure or dry the ink as it is applied, allowing for immediate handling and shipment of printed materials. Unlike traditional printing methods that require longer drying times, UV printing enables businesses to meet tight deadlines and efficiently manage large volumes of orders.

In addition to speeding up the production process, UV flatbed printers offer remarkable versatility. They can print on a wide range of substrates, from rigid materials like wood and metal to flexible items such as textiles and plastics. This adaptability not only broadens the scope of products that companies can offer but also minimizes the need for multiple printing systems. As production workflows become more streamlined and efficient, manufacturers can reduce their operational costs and increase profitability, ultimately revolutionizing the way printing businesses operate in a competitive market.

The global market for UV flatbed printers has experienced significant growth, driven by advancements in printing technology and increasing demand across various industries. As businesses seek ways to enhance productivity and efficiency, UV flatbed printers have emerged as a preferred choice for their versatility in printing on diverse materials, including wood, glass, and metal. Reports indicate that the market is projected to expand at a compound annual growth rate (CAGR) of over 8% in the coming years, highlighting the continued confidence in this technology.

Key factors fueling this growth include the rising popularity of customized printing solutions and the eco-friendly attributes of UV printing. Unlike traditional methods that often involve lengthy production times and environmentally harmful processes, UV printing offers immediate dry images, reducing waste and energy consumption. Furthermore, with the increasing trend toward personalized products and packaging, businesses are increasingly investing in UV flatbed printers to meet consumer demands while maintaining high-quality output. As more industries recognize the advantages of UV flatbed technology, its role in shaping the future of printing becomes more apparent.

UV flatbed printing is transforming various industries with its versatility and efficiency. This innovative technology allows for direct printing on a wide range of materials, including plastics, metals, glass, and textiles, making it indispensable in applications such as product design, packaging, and decoration. For instance, in the electronics sector, UV printers are widely used to create custom phone cases with intricate designs, significantly boosting consumer appeal. The ability to print high-resolution images with vibrant colors directly onto appliance surfaces is also revolutionizing the home appliance market, where aesthetics play a crucial role in customer choice.

When considering UV flatbed printers for your business, here are a few tips: first, assess the material compatibility of the printer to ensure it meets your specific production needs. Secondly, evaluate the printer's resolution and speed to optimize efficiency without compromising quality. Lastly, keep an eye on the market trends, as the UV printer market is projected to grow significantly, presenting ample opportunities for businesses looking to innovate.

As industries continue to embrace this technology, the projected growth of the UV printer market indicates a broader acceptance and integration into manufacturing processes. From wallpaper designs to automotive parts, the applications of UV flatbed printing are extensive, proving it to be a vital component in the evolution of modern manufacturing.

UV flatbed printers are leading the charge towards a more sustainable printing industry by significantly reducing the environmental impact traditionally associated with printing processes. According to a report by Smithers Pira, the global market for eco-friendly printing technologies is expected to reach $13 billion by 2025, illustrating a strong shift towards sustainable practices. UV technology uses ultraviolet light to cure inks as they are printed, which means less volatile organic compounds (VOCs) are released into the atmosphere, contributing to improved air quality and reduced health risks for workers in the printing industry.

Moreover, the durability of UV-cured inks enhances the longevity of printed materials, thereby decreasing the need for reprints and waste. A survey by the Environmental Protection Agency (EPA) indicated that UV printing can consume 40% less energy during the curing process compared to traditional methods. This energy efficiency, combined with the reduction of harmful emissions, positions UV flatbed printers as a critical component in the quest for a more sustainable future in printing. With these advancements, the printing industry is not only responding to consumer demand for environmentally responsible products, but also paving the way for innovative practices that prioritize sustainability.

| Feature | Description | Environmental Impact |

|---|---|---|

| Print Quality | High-resolution prints with vibrant colors and fine details. | Reduces ink waste due to precise application. |

| Material Versatility | Can print on various substrates including wood, glass, and metal. | Minimizes the need for additional coatings and treatments. |

| Drying Process | UV lights cure ink instantly, allowing for immediate handling. | Eliminates air drying, reducing energy consumption. |

| Sustainability | Utilizes eco-friendly inks that are low in volatile organic compounds (VOCs). | Contributes to improved air quality and reduced pollution. |

| Cost Efficiency | Fewer materials wasted due to precision printing methodologies. | Lower overall environmental footprint reduces costs associated with waste management. |