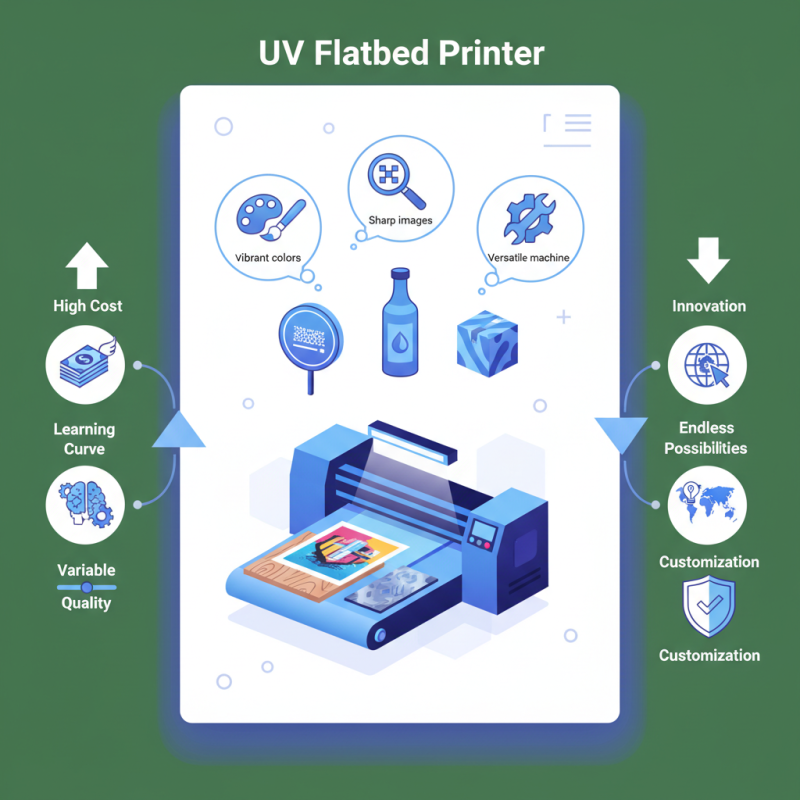

A UV flatbed printer is a versatile machine used in modern printing. It utilizes ultraviolet light to cure ink directly onto various surfaces. This innovation has changed the way businesses approach printing needs.

With a UV flatbed printer, designers can print on materials like wood, glass, and metal. These printers offer vibrant colors and sharp images. They are ideal for creating custom signage, promotional items, and packaging. The possibilities seem endless.

However, not everything is perfect. The cost of a UV flatbed printer can be high. Users may need time to learn how to operate the machine effectively. Additionally, the quality of printed materials may vary. It's essential to find the right settings for each project. This technology is impressive but requires careful consideration.

A UV flatbed printer is a versatile printing device that uses ultraviolet (UV) light to dry or cure ink as it is printed. This technology provides a unique advantage over traditional printing methods. UV printers can print on a multitude of flat surfaces, such as wood, glass, metal, and plastic, making them ideal for various industries.

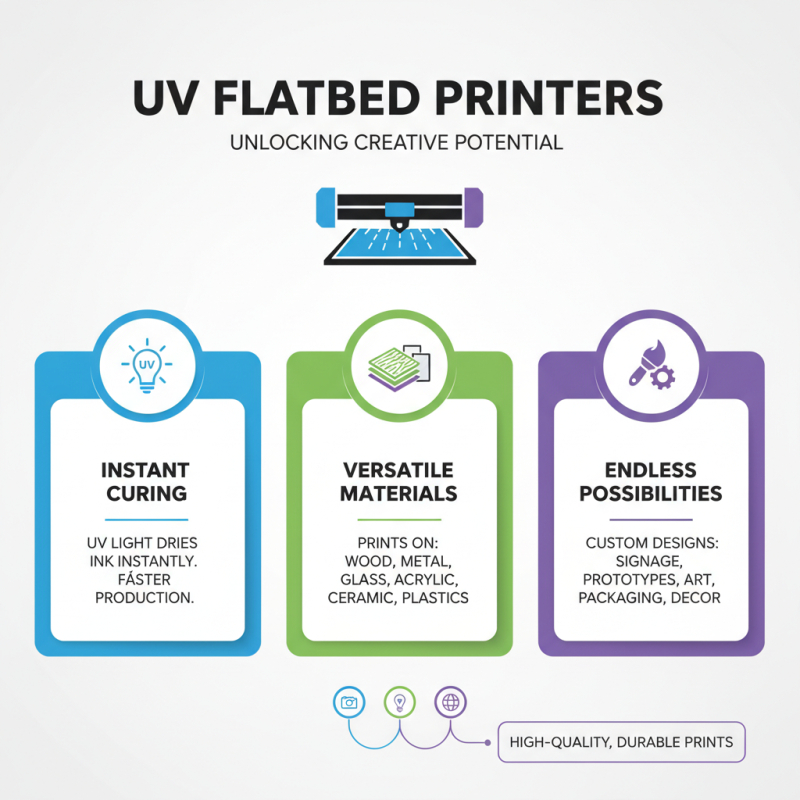

According to a recent market research report, the UV flatbed printer market is expected to reach $4 billion by 2026, growing at a CAGR of over 5%. This growth is driven by the demand for high-quality prints and the ability to print on unconventional materials. UV flatbed printers operate by using UV lamps that dry the ink instantly, allowing faster production times. This helps businesses meet high-demand situations efficiently.

Tips: Ensure you maintain a clean printer environment. Dust and debris can affect print quality. Regular maintenance is crucial. For the best results, test various ink types to find the best match for your materials. Not all printers handle every surface perfectly, so experimentation is key. Consider the weight and thickness of your materials; some printers may struggle with heavier items.

UV flatbed printers are increasingly popular due to their versatility and efficiency. These machines consist of several key components that work together to produce high-quality prints. The primary elements include the print head, UV light source, and the media platform. Each component plays a critical role in achieving precise printing.

The print head sprays UV-curable inks onto the media. This process requires careful calibration. If the inks are not dispensed correctly, the final print may suffer in quality. According to a market report from Smithers Pira, the global UV printing market is expected to reach $30 billion by 2025, highlighting the importance of precision in this technology.

The UV light source instantly cures the ink upon contact with the substrate. This rapid curing prevents smudging and allows immediate handling. However, the technology can be challenging to manage. An improperly set UV intensity can lead to issues like ink under-curing or over-curing, which affects durability. Users often find that fine-tuning equals better results.

Finally, the media platform supports the material being printed on. It must accommodate various thicknesses and shapes. Misalignment during printing can result in wasted materials and time. As reported by Keypoint Intelligence, many users report that consistently achieving high-quality prints requires rigorous training and experience. This shows an ongoing need for improvement in mastering UV flatbed printing technology.

A UV flatbed printer is a unique printing device. It uses ultraviolet light to cure or dry the ink as it's printed. This allows for a variety of materials to be printed on, including wood, metal, and glass. The initial step involves placing the substrate directly onto the flatbed. This is crucial as it ensures the material is perfectly aligned for the printing process.

The ink is then sprayed onto the surface. It forms a layer that is instantly cured by UV light. This quick curing process results in durable and vibrant images. It's essential to ensure the UV lamp is functioning correctly. A faulty lamp can lead to improperly cured prints, which may fade over time.

Tips: Regular maintenance of the printer is vital. It can prevent unexpected issues during the printing process. Also, experiment with different materials to see how they react to UV printing. Some materials may produce unexpected results, which can be beneficial or problematic, depending on your project needs. Be open to learning from these experiences to improve your skills.

UV flatbed printers have gained popularity due to their numerous advantages. They utilize ultraviolet light to cure inks instantly, allowing for high-quality prints on various materials. This technology is versatile, supporting everything from wood and metal to glass and acrylic. In today's creative landscape, this capability presents endless possibilities for custom designs.

One significant benefit is the ability to print directly onto objects. This reduces production time and eliminates the need for additional transfer processes. The resulting prints are vibrant and durable, often resistant to scratches and fading. However, achieving the right settings for each material can be a learning curve. Printer operators may face challenges with ink adhesion, requiring experimentation and adjustments.

Moreover, UV flatbed printers are known for their eco-friendliness. They emit fewer volatile organic compounds compared to traditional printers. This makes them a better option for businesses aiming to minimize their environmental footprint. Still, it's essential to ensure proper ventilation and safety measures, as UV light can pose risks. Continuous reflection and adaptation in practices can enhance the overall printing experience.

UV flatbed printing is transforming various industries by offering unique solutions for diverse applications. In signage, for instance, this technology enables the production of vibrant, durable outdoor displays. Reports indicate that about 40% of signage in retail now incorporates UV printing, resulting in longer-lasting visuals. The high adhesive quality of UV inks ensures that colors remain vibrant even after extended exposure to sunlight.

Another significant application is in the packaging sector. The global demand for personalized packaging is growing, with UV flatbed printers allowing for customization on materials like cardboard and wood. Studies show that 55% of consumers are influenced by packaging design. This highlights how effective prints can enhance product appeal. However, the rapid advancements in UV printing also pose challenges for small manufacturers, who may struggle to keep up with technological changes.

In the decor industry, UV printers enable the creation of bespoke furniture designs and wall art. The versatility of materials, ranging from glass to metal, expands creative possibilities. However, industry reports underline the environmental concerns related to UV inks, specifically their chemical components. This raises questions about sustainability in a field increasingly relying on innovative yet potentially harmful products.

| Industry | Application | Benefits of UV Flatbed Printing |

|---|---|---|

| Signage | Outdoor and indoor signs, banners | Durable, weather-resistant prints |

| Packaging | Custom packaging, boxes, labels | High-quality, full-color prints |

| Promotional Products | Branded merchandise, giveaways | Versatile printing on various materials |

| Interior Décor | Wall art, custom furniture finishes | Unique designs with vibrant colors |

| Textiles | Custom prints on fabrics | Durable prints that withstand washing |

| Automotive | Custom car wraps, decals | Long-lasting and vibrant graphics |