In the rapidly evolving landscape of printing technology, the demand for high-efficiency and versatile printing solutions is at an all-time high. According to a recent report by Smithers Pira, the global UV printing market is projected to reach $4.3 billion by 2024, driven by the need for sustainable and quality printing applications.

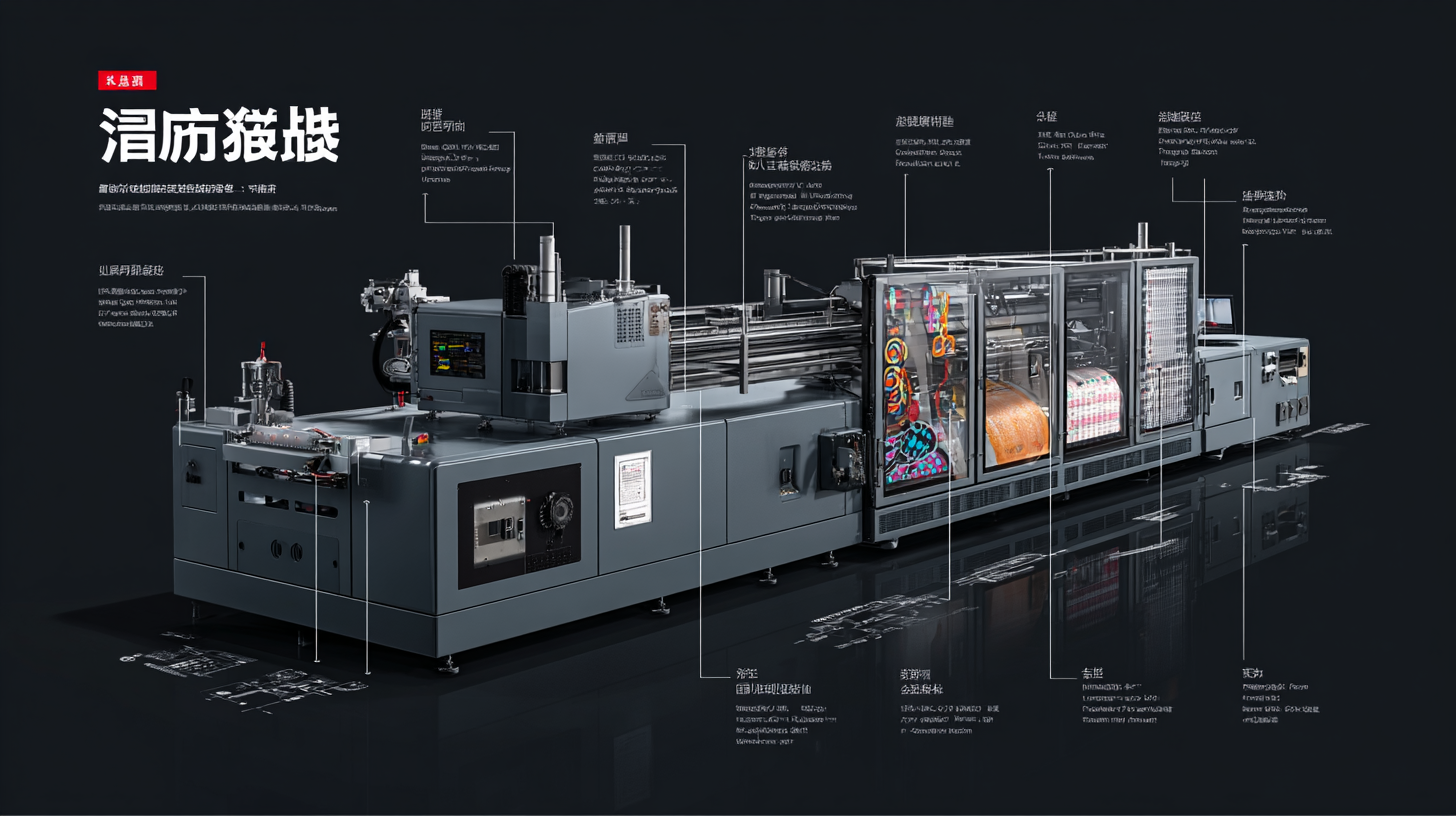

Central to this growth is the Positioning UV Printer, which offers enhanced precision and adaptability for a myriad of substrates, ranging from plastics to textiles. These printers not only reduce drying times but also match the increasing consumer expectations for high-quality and durable prints. By unlocking the full potential of Positioning UV Printers through comprehensive technical specifications, manufacturers and businesses can stay ahead in this competitive landscape, ensuring they meet evolving market demands while maximizing efficiency and productivity.

Central to this growth is the Positioning UV Printer, which offers enhanced precision and adaptability for a myriad of substrates, ranging from plastics to textiles. These printers not only reduce drying times but also match the increasing consumer expectations for high-quality and durable prints. By unlocking the full potential of Positioning UV Printers through comprehensive technical specifications, manufacturers and businesses can stay ahead in this competitive landscape, ensuring they meet evolving market demands while maximizing efficiency and productivity.

When considering the positioning of UV printers, several key factors play a crucial role in maximizing their potential. For instance, the recent rise in the global printers market, projected to grow from $51.97 billion in 2024 to $65.50 billion by 2032, highlights the increasing demand for advanced printing technology. This growth underscores the necessity for users to understand the specific characteristics of their UV printers, such as print resolution, speed, and material compatibility, which can significantly affect the final output quality.

Moreover, the emergence of new products like the eufyMake UV Printer E1 illustrates the innovation in this sector. This model, priced at $1,699, boasts features tailored for hobbyists and small businesses, emphasizing the need for effective positioning to appeal to the target demographic. Key elements to consider include the printer’s ability to create intricate designs with 3D textures, which can enhance creative projects and lead to greater customer satisfaction. As the market continues to evolve, understanding these positioning factors will be essential for leveraging the full capabilities of UV printing technology.

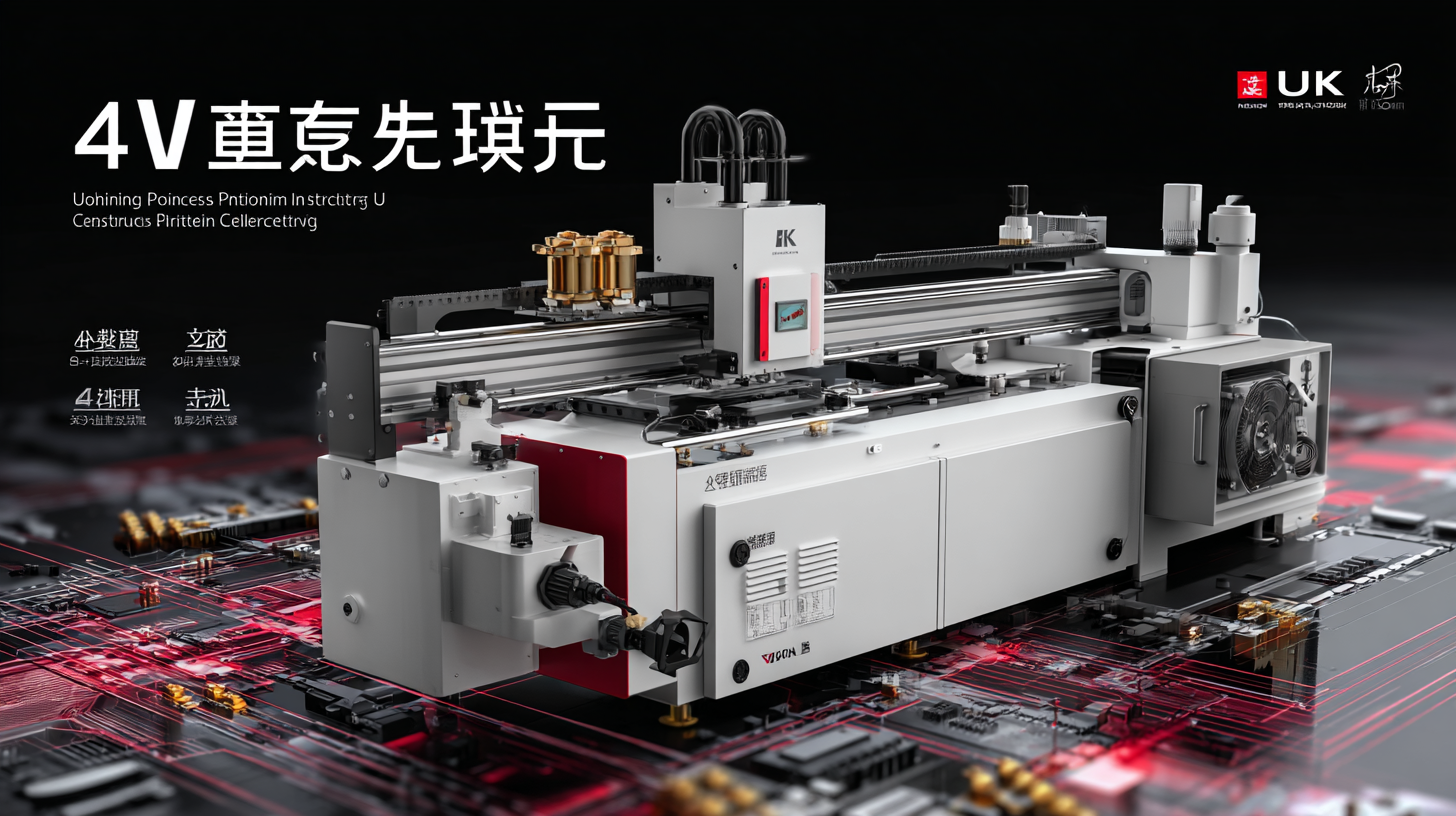

When it comes to maximizing the performance of a UV printer, understanding its technical specifications is crucial. Essential specifications like print resolution, curing technology, and ink type directly influence the output quality and efficiency. A high print resolution, measured in DPI (dots per inch), ensures that the details are crisp and vibrant, making it ideal for high-quality graphics. Additionally, the choice of curing technology—such as LED or mercury vapor—affects not only the drying time but also energy consumption and the overall eco-friendliness of the printing process.

Another key specification to consider is the ink composition. UV inks, known for their quick-drying properties, can significantly enhance productivity. However, it is important to choose inks compatible with the substrate being printed to achieve optimal adhesion and durability. Understanding the printer's maximum media size and thickness capacity is also vital, as these factors dictate the range of projects that can be tackled. By focusing on these technical specifications, businesses can unlock the full potential of their UV printers, leading to superior print quality and increased operational efficiency.

When it comes to selecting the best UV printer, a comparative analysis of leading models can significantly guide purchasing decisions. Recent studies illustrate that the market for UV printers is projected to grow at a compound annual growth rate (CAGR) of around 6.2% over the next five years, driven by increasing demand in various sectors including packaging, signage, and decorative print applications. Key specifications to consider in UV printers are print resolution, curing speed, and versatility in material compatibility.

Among the top models available, several standout features differentiate their performance and applicability. For instance, some UV printers offer advanced UV curing technology, enabling faster production times without compromising print quality. Their ability to handle a wide range of substrates, from rigid materials to flexible films, illustrates the versatility that professionals increasingly require. Furthermore, the integration of user-friendly interfaces and automation solutions enhances workflow efficiency. With a thorough understanding of these comparative benefits, businesses can optimize their investment in UV printing technology to meet current and future market demands.

Implementing a UV printer in your business workflow can significantly enhance productivity and expand your capabilities. The integration of UV printing technology not only offers quick drying times but also provides versatility in materials, allowing businesses to print on a variety of substrates. To maximize the potential of your UV printer, it’s crucial to develop a structured approach that incorporates best practices. This involves proper training for staff, understanding the technical specifications of your printer, and maintaining consistent quality control throughout the printing process.

Moreover, staying updated with the latest industry trends can influence how you leverage your UV printer. For instance, the emergence of new advancements in the digital printing sector underscores the importance of continuous improvement in your workflows. Engaging in proactive maintenance schedules and utilizing software solutions for design and print management can streamline operations. By focusing on these best practices, you can ensure that your UV printer becomes a valuable asset in driving efficiency and innovation within your organization.

| Feature | Specification | Best Practices |

|---|---|---|

| Print Speed | Up to 50 m²/h | Optimize settings for materials |

| Layer Thickness | Variable: 0.5 - 10 mm | Select layer thickness according to the job |

| Print Resolution | Up to 1200 dpi | Use high-resolution settings for detailed designs |

| Ink Types | UV-curable inks | Ensure ink compatibility with substrates |

| Connectivity | USB, Ethernet | Use stable connections for large file transfers |

| Dimensions | 2000 x 1200 x 1500 mm | Plan workspace and access paths accordingly |

Effective placement strategies for UV printers can significantly enhance return on investment (ROI) by optimizing production efficiency and minimizing downtime. Understanding your workspace is crucial; UV printers should be placed in well-ventilated areas with adequate space around them for maintenance and operations. This allows for streamlined workflows and makes it easier to handle substrates and finished products without unnecessary delays. Moreover, proximity to other essential equipment can further enhance efficiency, ensuring that jobs move seamlessly from one stage to another.

Another vital consideration is the accessibility of power sources and the organization of materials. By positioning a UV printer near power outlets and supply areas, you can reduce the time spent on setup and material handling. Additionally, ensuring that your UV printer is placed away from high-traffic zones will help mitigate the risk of accidents and interruptions, ultimately leading to higher productivity levels. Implementing these strategies will not only improve operational workflows but also contribute to greater overall profitability, making effective UV printer placement a critical aspect of maximizing ROI.