In recent years, the digital printing industry has witnessed significant advancements, particularly in the domains of Dtf printers and UV printers, which have become essential tools for achieving high-quality and efficient printing results. According to a recent report by Smithers Pira, the global digital printing market is projected to grow at a CAGR of 5.6%, reaching a value of $29 billion by 2025. This growth is largely driven by the increasing demand for customized and short-run printing solutions, where Dtf printer and UV printer technologies play a crucial role.

These printers not only enhance productivity and reduce waste but also offer versatility in printing on various substrates, making them highly sought after in sectors such as textiles, packaging, and promotional materials. As China continues to lead in manufacturing excellence and export strength, understanding these industry standards becomes imperative for businesses looking to leverage the competitive advantages offered by Dtf and UV printers.

When selecting the best DTF and UV printers, it's crucial to consider several key features that define their performance and suitability for small businesses. Among these features, print quality stands out as a top priority. Reports indicate that the latest DTF printers can achieve high-resolution outputs, crucial for businesses aiming to produce vibrant and detailed designs on fabrics. Additionally, the integration of advanced technology, such as cold transfer printing in UV DTF printers, enhances versatility, allowing for the application of prints on a range of surfaces and textures.

Another significant factor is the printer's operational efficiency. Businesses are increasingly looking for printers that not only provide high-quality prints but also streamline the workflow. For instance, the latest models are designed to minimize setup times and reduce waste, which is vital for small operations looking to maximize productivity. Furthermore, ease of use and maintenance plays a pivotal role, as user-friendly interfaces and reliable support can greatly influence the overall experience of running a printing operation. By focusing on these fundamental features, small businesses can make informed decisions that will enhance their production capabilities and market presence.

When evaluating suppliers for DTF (Direct to Film) and UV printing equipment, it is crucial to consider a few key factors that can significantly impact your production quality and efficiency. According to a recent market analysis, the DTF printing industry is projected to grow by 12% annually, emphasizing the need for reliable printers that ensure high-quality outcomes. Look for suppliers that provide comprehensive technical support and maintenance services, as this can reduce downtime and operational costs.

**Tip:** Always request a sample print from potential suppliers before making a purchase. Assess the color vibrancy, durability, and adhesion quality of the prints to ensure they meet your project requirements. This hands-on evaluation can save you from investing in subpar equipment that may perform poorly in real-world applications.

Another important aspect is to review the supplier’s reputation in the industry. According to a survey conducted by the Specialty Graphic Imaging Association, 67% of businesses prioritize supplier longevity and customer feedback when selecting equipment partners. Engage with peer reviews and case studies to understand the experiences of other businesses using the same equipment. This insight can help you gauge the reliability and performance of the printer you are considering.

**Tip:** Attend industry expos and conferences to network with other professionals and gather firsthand insights about suppliers. Direct interactions can provide valuable perspective on the long-term satisfaction and support experiences of various printing solutions in the market.

In the dynamic world of DTF (Direct to Film) and UV (Ultraviolet) printing, print quality standards are critical benchmarks that define the success and appeal of printed products. These standards encompass various aspects, including color accuracy, resolution, and durability. For DTF printers, achieving high print quality means ensuring that vibrant colors transfer seamlessly onto fabrics, maintaining richness and crispness that capture the eye. The use of high-quality films and inks, along with meticulous calibration, plays a significant role in meeting these standards.

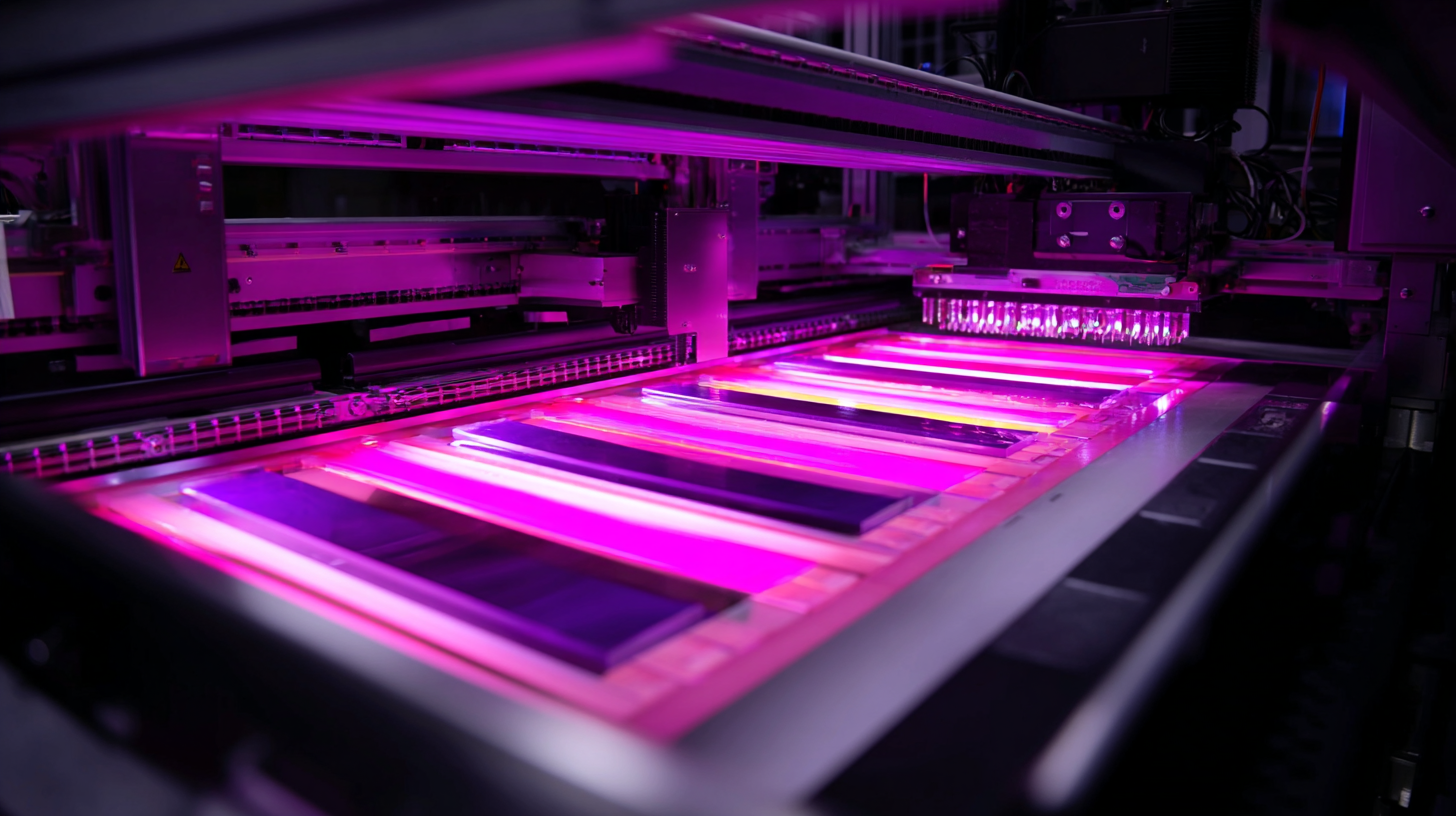

On the other hand, UV printing is synonymous with its unique ability to cure inks instantly using ultraviolet light, allowing for stunning finishes and intricate designs. Print quality standards in this domain focus on adhesion and resistance to fading, making it essential for businesses to select UV printers that can deliver consistency across diverse substrates. Understanding the technical specifications, such as dot gain and color gamut, not only aids in selecting the right equipment but also ensures that the end product meets both industry standards and customer expectations. As businesses navigate the complexities of print technology, adhering to these quality standards is imperative for maintaining competitive advantage.

Proper maintenance of DTF (Direct to Film) and UV printers is crucial for ensuring their longevity and optimal performance. One of the key practices is to regularly clean the print heads and nozzles. Accumulated ink residue can clog the nozzles, leading to print quality issues. Use specific cleaning solutions recommended by the manufacturer, and incorporate routine checks into your maintenance schedule to catch potential problems early.

Another essential maintenance practice involves monitoring ink levels and replacing cartridges before they run out completely. Low ink levels can cause air to enter the system, leading to inconsistent prints and potential damage to the printer. Additionally, keep the printer in a dust-free environment and ensure it is stored in a temperature-controlled space, as extreme temperatures can affect the ink consistency and printer components. By adhering to these practices, you can significantly extend the lifespan of your DTF and UV printers while maintaining high-quality output.

| Printer Type | Max Resolution | Ink Type | Print Speed (m²/h) | Maintenance Frequency | Typical Lifespan |

|---|---|---|---|---|---|

| DTF Printer | 1440 dpi | Water-based ink | 20 | Weekly | 5-7 years |

| UV Printer | 1200 dpi | UV curable ink | 15 | Monthly | 7-10 years |

| Eco-Solvent Printer | 1440 dpi | Eco-solvent ink | 18 | Bi-weekly | 6-8 years |

| Dye-Sublimation Printer | 4800 dpi | Dye-sublimation ink | 12 | Every print job | 4-6 years |

When it comes to selecting the best DTF (Direct to Film) and UV (Ultraviolet) printers, a critical consideration is the balance between cost and quality. Many businesses are faced with the challenge of managing tight budgets while still striving to achieve high-quality prints that meet customer expectations. Understanding this balance requires a careful analysis of what each printer type offers and how that aligns with specific printing needs.

Investing in a high-quality printer may come with a higher initial price tag, but it often pays off in the long run through superior print fidelity, speed, and durability. For example, UV printers excel in producing vivid colors and detailed images, making them ideal for high-end applications. However, the operational costs may also be higher due to maintenance and materials. Conversely, while DTF printers might have a lower upfront cost, businesses must consider the long-term implications of print quality and the potential need for reprints, which can ultimately drive up costs. Careful deliberation between these factors is essential for making well-informed decisions that align with both the budget and the quality desired in the final product.