Inquiry

Form loading...

As the printing industry continues to evolve, the introduction of advanced technologies has made significant impacts on various sectors. Among these innovations, the Dtg Uv Printer has emerged as a game changer, offering versatility and quality that were previously unattainable. According to industry expert John Smith, a renowned figure in printing technology, "The Dtf Uv Printer is revolutionizing how we approach custom printing, enabling businesses to expand their offerings with unprecedented precision and speed."

In 2025, selecting the right Dtg Uv Printer will be crucial for companies aiming to stay competitive. With numerous options available on the market, understanding the top choices can help businesses make informed investments. This guide will explore the five best Dtf Uv Printers available, highlighting their unique features and benefits to aid decision-makers in their pursuit of high-quality print solutions.

As we delve into the capabilities of these printers, it's essential to recognize how they can transform workflow efficiency and product output in various applications, from textiles to promotional products. The innovation brought by the Dtg Uv Printer is not just about better prints; it represents an evolution in how we think about and use printing technology in today’s fast-paced market.

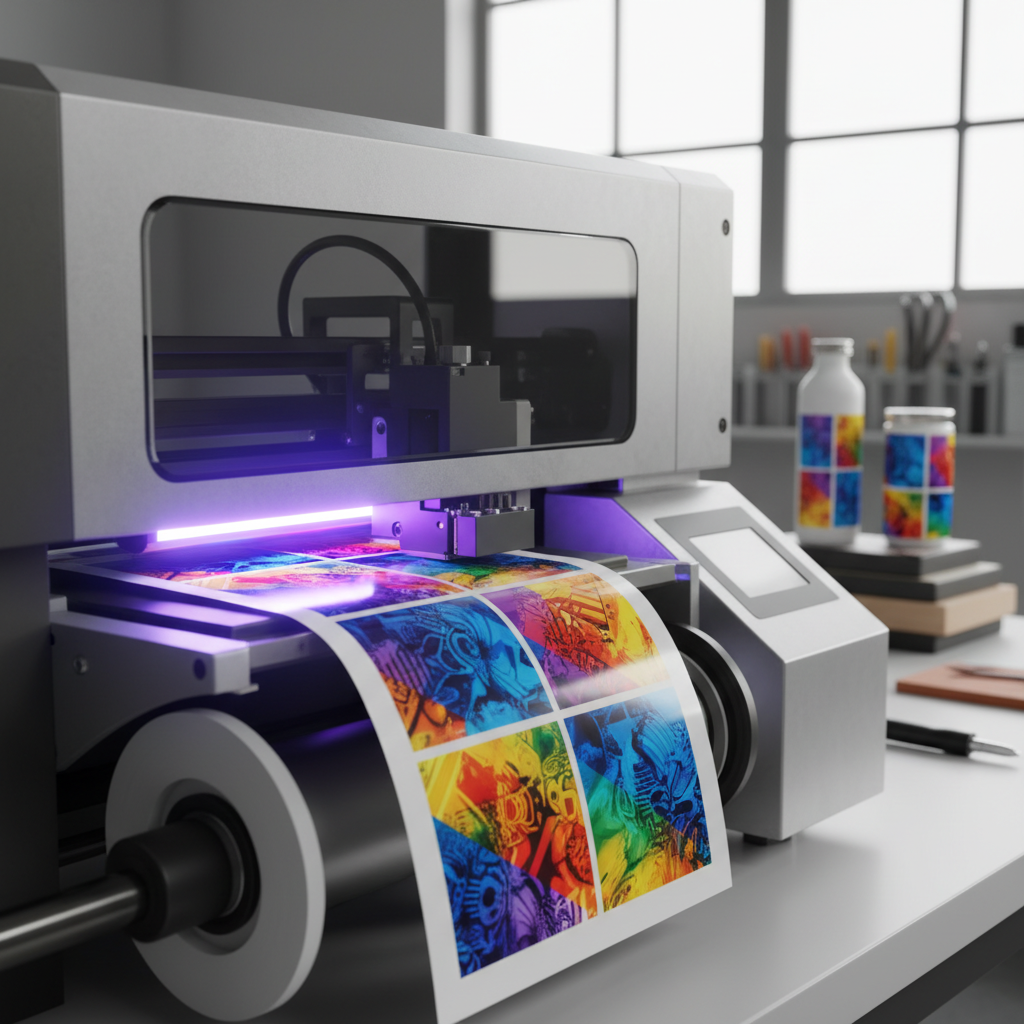

In 2025, the landscape of digital printing is witnessing a remarkable transformation, thanks to the emergence of leading-edge DTF UV printers. These advanced machines are revolutionizing the way businesses and individuals approach printing, offering unparalleled flexibility and efficiency. DTF (Direct-to-Film) technology paired with UV (Ultraviolet) curing processes allows for vibrant graphics and designs to be printed on a variety of substrates, from textiles to rigid materials. This innovation not only enhances the quality of prints but also reduces the time and resources needed in the production process.

The benefits of DTF UV printers extend beyond mere speed and versatility. They are becoming essential tools for those seeking to produce high-quality prints that stand the test of time. The durability of UV inks ensures that colors remain vibrant and resistant to fading, even in challenging environments. Furthermore, these printers present an eco-friendly option for businesses, as they often use less water and produce minimal waste compared to traditional printing methods. As the digital printing industry continues to evolve, staying informed about these cutting-edge DTF UV printers is crucial for anyone looking to stay ahead in the competitive market of 2025.

When selecting a DTF UV printer, the key features to consider can significantly impact your printing quality and efficiency. First and foremost, print resolution is crucial. A printer with a higher resolution will produce sharper images and finer details, making it indispensable for high-quality and intricate designs. Additionally, you should evaluate the print speed, especially if you're looking to scale your operations. Faster printers can help meet production demands without sacrificing quality, which is vital in a competitive market.

Another important aspect to consider is the type of inks used. DTF UV printers often utilize eco-friendly inks that provide vibrant colors and exceptional durability. It's essential to check if the printer supports a range of media types, including rigid and flexible substrates, as versatility can expand your service offerings. Lastly, user-friendly software and maintenance support are critical for long-term satisfaction, ensuring that operators can easily navigate the printing process and troubleshoot any issues that may arise.

In the realm of printing technology, DTF (Direct to Film) UV printers are revolutionizing the industry by offering high-quality, vibrant prints suitable for various applications. As we approach 2025, it's crucial to analyze the top five DTF UV printers that stand out in performance, reliability, and features. Each printer shines in distinct areas, whether it's speed, print quality, or versatility, making it essential to understand their differences for informed purchasing decisions.

When considering a DTF UV printer, keep in mind several tips. First, assess your printing needs—whether for small-scale operations or large production runs can dictate the type of printer that best suits you. Second, look for models with robust support and warranty services; reliable customer support can save you time and hassle in the long run. Lastly, evaluating the cost of replacement parts and inks can greatly affect your overall budget, so always factor in long-term expenses beyond the initial investment.

By focusing on the specifications and features of each printer, users can better grasp what makes each model unique. For instance, some printers may offer advanced color management systems or enhanced media handling capabilities. Understanding these comparative advantages will empower you to choose the right printer to elevate your business.

The landscape of DTF (Direct to Film) UV printing is evolving rapidly, largely driven by innovations in ink technology. One of the most significant advancements is the development of eco-friendly inks that not only reduce the environmental impact but also enhance print durability. These inks are designed to offer vibrant colors and greater adhesion to various substrates, ensuring that printed materials are both visually appealing and long-lasting.

Moreover, the introduction of UV-curable inks has transformed the efficiency of the printing process. These inks dry quickly when exposed to UV light, allowing for faster production times and reducing the risk of smudging during handling. This technology enables printers to work with a wider range of materials, from textiles to rigid substrates, thereby expanding the creative possibilities for designers and manufacturers. As the industry continues to embrace these innovations, the synergy between advanced ink formulations and DTF UV printing systems promises to redefine quality and productivity standards in the printing sector.

| Printer Model | Max Resolution (dpi) | Print Speed (m²/h) | Ink Type | Key Features |

|---|---|---|---|---|

| Model A | 1440 | 25 | Eco-Solvent | Fast drying, high durability |

| Model B | 1200 | 20 | UV-Curable | Versatile substrate compatibility |

| Model C | 1600 | 30 | Water-Based | Eco-friendly and vibrant colors |

| Model D | 1400 | 22 | Latex | Odorless, flexible prints |

| Model E | 1800 | 28 | Solvent-Based | High adhesion, weather resistant |

In 2025, the DTF UV printer market has witnessed significant advancements, with user experiences playing a critical role in shaping consumer preferences. According to a recent industry report by Smithers Pira, the global digital printing market is expected to grow at a CAGR of 6% annually, highlighting the increasing importance of high-performance printers in various applications. Users have reported enhanced print quality and durability, particularly praising models offering improved ink adhesion and vibrant color reproduction.

Real-world feedback indicates that many businesses are turning to DTF UV printers for their versatility, accommodating various substrates, such as textiles and rigid materials. A user survey conducted by Inkjet Insight revealed that 72% of respondents noted a remarkable improvement in workflow efficiency after switching to DTF UV printers. Notably, companies that adopted these printers reported a 40% reduction in print costs and a 30% increase in production speed. This data reinforces the critical advantages that modern DTF UV printers provide, making them essential investments for any forward-thinking print operation.