Inquiry

Form loading...

In today's competitive manufacturing landscape, optimizing production processes is essential for companies aiming to enhance efficiency and reduce costs. A recent report from Smithers Pira highlights that the UV printing market is projected to grow at a compound annual growth rate (CAGR) of 10.7% from 2021 to 2026, underscoring the rising demand for advanced printing technologies like the UV Cylinder Printer. This innovative equipment not only accelerates production speeds but also significantly improves print quality and versatility, allowing businesses to meet diverse customer requirements more effectively. By leveraging the capabilities of a UV Cylinder Printer, manufacturers can streamline their workflows, reduce waste, and ultimately drive profitability. This guide will explore key strategies and best practices to fully optimize production with a UV Cylinder Printer, positioning organizations to capitalize on market opportunities in this rapidly evolving sector.

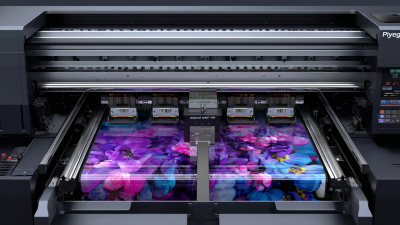

UV cylinder printing technology represents a significant advancement in the realm of printing, particularly for cylindrical objects. The process utilizes ultraviolet light to cure or dry the ink as it is printed. This method allows for vibrant color application and exceptional detail on surfaces that may be traditionally challenging to print on, such as glass, metal, or plastics.

UV cylinder printing technology represents a significant advancement in the realm of printing, particularly for cylindrical objects. The process utilizes ultraviolet light to cure or dry the ink as it is printed. This method allows for vibrant color application and exceptional detail on surfaces that may be traditionally challenging to print on, such as glass, metal, or plastics.

One of the primary advantages of UV cylinder printing is its versatility. It can accommodate a wide range of materials and shapes, making it ideal for personalized products and custom designs. Additionally, the quick-drying nature of UV ink significantly enhances production efficiency, reducing turnaround times. Since the ink is cured instantly, there's less risk of smudging or distortion, ensuring high-quality results every time. Moreover, UV printing is also more environmentally friendly compared to conventional printing methods, as it often uses fewer solvents and produces less waste.

When selecting a UV cylinder printer for your production, several crucial factors must be taken into account to ensure optimal results.

Firstly, the printer’s capabilities concerning substrate versatility are paramount.

According to Smithers Pira, the global market for UV printing is expected to grow at a CAGR of 6.5% from 2021 to 2026.

This growth highlights the increasing demand for printers that can handle a wide array of materials, from glass and metal to plastics and fabric.

A printer that can adapt to different substrates can significantly enhance production efficiency and open new avenues for product offerings.

Additionally, print resolution and speed are essential considerations.

Current industry standards suggest that a printer should have a minimum resolution of 1200 DPI to meet quality expectations in high-end markets,

such as packaging and branding. Speed is also critical; with the average time to print a full cylinder at around 30 seconds to 1 minute,

choosing a model that optimizes throughput without compromising on quality can lead to substantial productivity gains.

Understanding these factors, along with ongoing technological advancements, will position your production line to take full advantage of what UV cylinder printing technology has to offer.

To operate a UV cylinder printer efficiently, it is essential to start with proper setup. Begin by ensuring the printer is located on a stable, level surface to avoid any vibrations during operation that could affect print quality. Calibrating the printer settings according to the specific materials being used is crucial. Different substrates require different settings for optimal adhesion and color reproduction, so refer to the manufacturer's guidelines for each material.

In addition to initial setup, regular maintenance is vital for the long-term performance of your UV cylinder printer. This includes routine cleaning of the printhead and ensuring that the ink supply system is functioning correctly. Moreover, implementing a consistent workflow can streamline production. Organizing the workspace and keeping a stock of frequently used materials will reduce downtime, allowing for a more efficient printing process. By combining careful setup with ongoing maintenance and a well-planned workflow, you can significantly enhance the productivity of your UV cylinder printing operations.

Maintaining a UV cylinder printer is essential for ensuring its longevity and optimal performance in the production process. Regular maintenance not only helps in reducing downtime but also enhances the quality of prints.

According to a report by Smithers Pira, printers that are well-maintained see a 25% increase in their operational lifespan compared to those that are neglected. To achieve this, it is crucial to clean the printer heads and ink delivery systems regularly, as residual ink can lead to clogged nozzles and decreased print quality.

Maintaining a UV cylinder printer is essential for ensuring its longevity and optimal performance in the production process. Regular maintenance not only helps in reducing downtime but also enhances the quality of prints.

According to a report by Smithers Pira, printers that are well-maintained see a 25% increase in their operational lifespan compared to those that are neglected. To achieve this, it is crucial to clean the printer heads and ink delivery systems regularly, as residual ink can lead to clogged nozzles and decreased print quality.

Tip: Schedule routine maintenance checks every three months to inspect all mechanical components and replace any worn-out parts, ensuring everything operates smoothly.

Another best practice is to monitor ink levels and replace them promptly. Low ink levels can cause inconsistencies in printing, which can affect the overall quality of produced materials. A study by the Printing Industries of America indicates that printers with consistent monitoring for ink usage reduce waste by up to 30%.

Tip: Implement an automated ink monitoring system that alerts you when levels are low, preventing unexpected interruptions in your production timeline.

By adhering to these maintenance protocols, you can effectively prolong the life of your UV cylinder printer while maximizing its performance and print quality.

UV cylinder printing has revolutionized various industries by offering innovative applications that enhance production and creativity. In the packaging industry, UV cylinder printers enable brands to produce eye-catching labels and packaging with vibrant colors and intricate designs. The ability to print on curved surfaces allows for more dynamically branded opportunities that attract customers, making products stand out on the shelves.

In the realms of decor and personalized merchandise, UV cylinder printing opens doors to unique creations. Businesses can produce custom gifts, promotional items, and home decor pieces that feature high-resolution images and detailed graphics. This technology not only provides durability but also allows for a wide variety of materials to be printed on, including glass, metal, and plastic. As a result, industries can cater to consumer demands for personalization and high-quality products, ultimately optimizing their production processes and expanding their market reach.