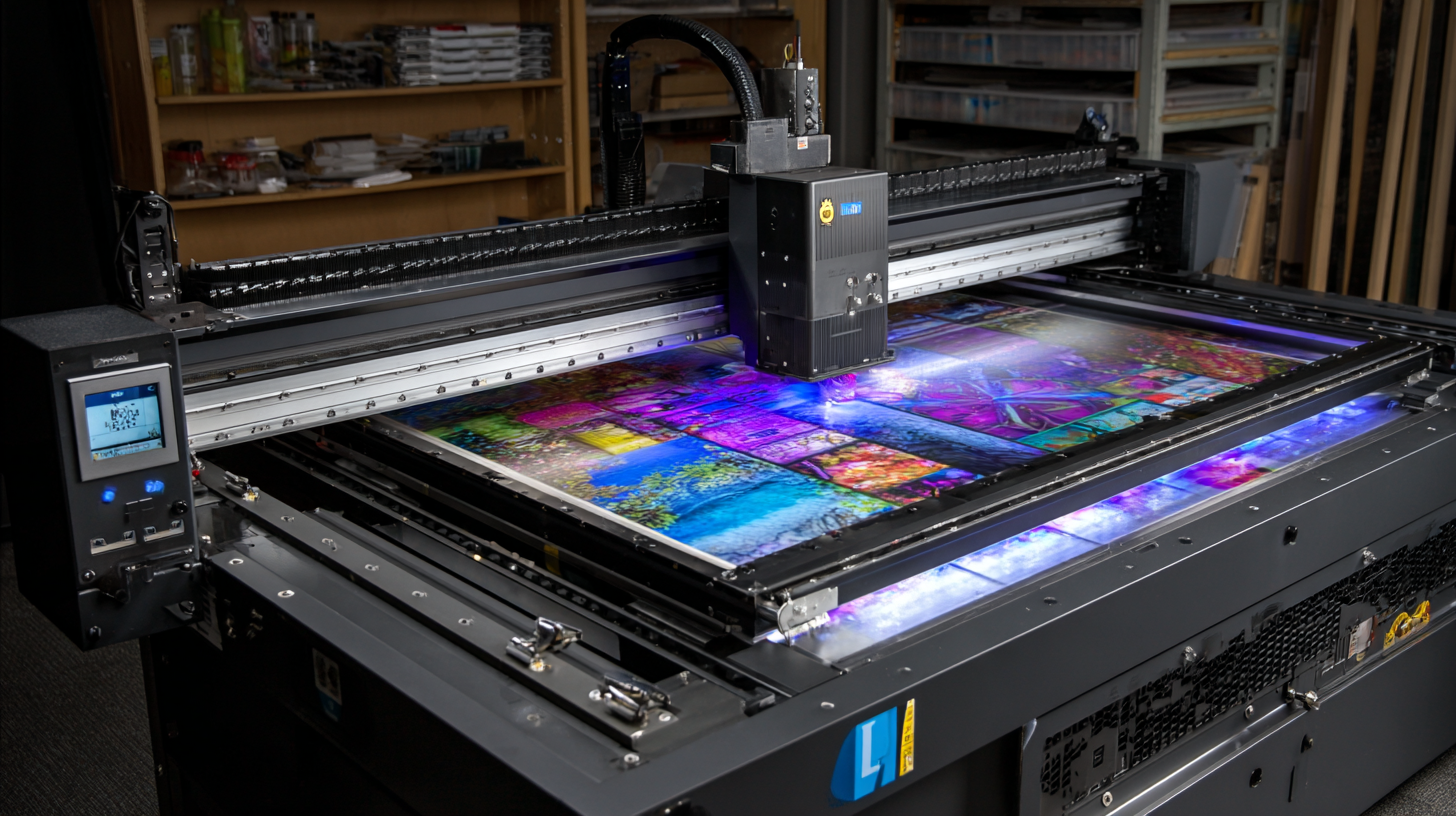

In today’s fast-paced printing industry, the demand for efficiency and versatility continues to rise, making the UV flatbed printer a game-changer for businesses seeking to maximize productivity. This innovative printing solution allows for high-quality output on a diverse range of materials, from rigid substrates to flexible media, ensuring that every project meets the highest standards. The benefits of utilizing a UV flatbed printer extend beyond mere convenience; they include faster turnaround times, reduced operational costs, and the ability to create stunning graphics that captivate audiences. As we delve into the various types of products that can be achieved with UV flatbed printing, we will explore their unique characteristics and applicable markets, ultimately shedding light on how these advanced technologies can revolutionize your printing operations and contribute to sustained business success.

The future of UV flatbed printing is poised for remarkable transformation by 2025, driven by innovative technology and evolving industry demands. One of the most significant trends is the integration of automation and artificial intelligence into the printing process. This advancement not only enhances precision but also streamlines production workflows, allowing for faster turnaround times. As businesses seek to reduce operational costs, automated UV flatbed printers will enable manufacturers to fulfill bulk orders with minimal human intervention, enabling them to focus on creative design and customer engagement.

Another trend shaping the future landscape of UV flatbed printing is the growing emphasis on sustainability. With a global shift towards environmentally friendly practices, manufacturers are increasingly adopting eco-solvent inks and energy-efficient machines. This move not only reduces the carbon footprint but also meets the rising consumer demand for sustainable products. By 2025, we can expect UV flatbed printers to incorporate recyclable materials and waste reduction technologies, ensuring that businesses can produce high-quality prints while contributing to a healthier planet. As these trends continue to grow, they will redefine how companies leverage UV flatbed printing to maximize both efficiency and environmental responsibility.

When selecting the right UV flatbed printer for your business, it's essential to focus on several key factors that can maximize efficiency and output quality. According to a recent industry report, businesses can improve printing speed and efficiency by up to 30% when opting for advanced UV technologies that offer faster curing times and higher resolution outputs. This is particularly crucial in high-demand environments where time and quality are critical.

Another vital consideration is the range of media compatibility. A comprehensive study has shown that printers featuring versatile substrates can enhance production flexibility, enabling businesses to meet diverse client needs without significant downtime. For instance, the ability to print on materials such as wood, glass, and metal not only broadens service offerings but also taps into lucrative niche markets. Moreover, evaluating maintenance requirements and operational costs, including ink consumption and energy efficiency, can lead to significant long-term savings, thereby reinforcing the printer's ROI. Therefore, making informed decisions based on these best practices can lead to sustained business growth and a competitive edge in the market.

When it comes to UV flatbed technology, innovation is key to enhancing productivity. By leveraging the latest advancements, businesses can streamline their processes and produce high-quality outputs. One effective technique is to optimize your workflow by integrating automation. This allows for a seamless operation where tasks such as loading and unloading materials can be performed without manual intervention, significantly reducing downtime.

**Tip:** Implementing software that manages production schedules can help you better allocate resources and minimize delays, ensuring that your UV flatbed printer operates at peak efficiency.

Another strategy to enhance productivity is to experiment with different UV inks and substrates. Selecting the right combination can lead to superior adhesion and vibrant colors, reducing the need for reprints and wasted materials. Additionally, regular maintenance of your printing equipment ensures that it remains in top condition, which can greatly reduce the risk of costly breakdowns.

**Tip:** Keep a maintenance log and schedule regular check-ups for your UV flatbed printer to prevent unexpected issues and extend its lifespan, ultimately benefiting your overall productivity.

Maintaining a UV flatbed printer effectively can significantly enhance its longevity and performance, ultimately leading to improved efficiency and cost savings. One of the most cost-effective strategies for upkeep begins with regular cleaning of the print heads and surfaces. Dust and ink residue can accumulate, resulting in poor print quality and increased maintenance costs. Utilizing specialized cleaning solutions and following manufacturer guidelines can ensure that the printer continues to operate smoothly and produce vibrant prints.

Another crucial aspect of maintenance is the regular inspection of mechanical components, such as belts and bearings. Over time, wear and tear can affect the precision of prints. Scheduling routine checks can help identify issues before they escalate, avoiding costly repairs. Additionally, investing in staff training to handle minor repairs and best operational practices can further reduce long-term costs. Emphasizing a proactive maintenance approach not only enhances the efficiency of UV flatbed printers but also maximizes the return on investment, ensuring that businesses can scale their operations without the burden of frequent breakdowns.

Maximizing output quality in UV flatbed printing processes relies on several key factors that can significantly impact overall performance. According to a report from Smithers Pira, the UV printing market is expected to grow by over 20% annually, driven by advancements in technology and the increasing demand for sustainable printing solutions. To ensure that businesses capitalize on this growth, optimizing printing processes is essential. Techniques such as calibrating print heads regularly and utilizing high-quality inks are fundamental. Calibration helps maintain consistent color accuracy and reduces the likelihood of errors, while premium inks can enhance adhesion and durability, resulting in superior print quality.

Another critical aspect involves understanding the substrate compatibility with UV inks. A study published by Vandergriff confirms that selecting the right materials can amplify the vibrancy and longevity of printed products. Substrates like rigid plastics and glass can yield stunning results when paired correctly with UV printers. Furthermore, implementing advanced software solutions for pre-press optimization can streamline workflows, reducing time-to-market without sacrificing quality. By focusing on these innovative approaches, businesses can achieve not only higher efficiency but also enhanced output quality in their UV flatbed printing operations.