Inquiry

Form loading...

In the rapidly evolving landscape of commercial printing, the demand for high-quality, versatile solutions has never been more critical. According to a report by Smithers Pira, the digital printing market is expected to reach $292 billion by 2024, with UV printing technologies playing a pivotal role in this growth.

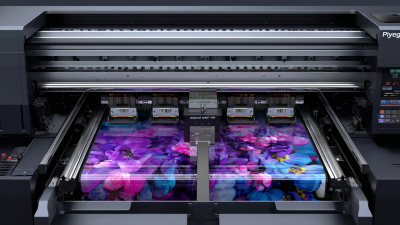

Big UV Printers, renowned for their ability to handle a variety of materials and provide exceptional print quality, are becoming indispensable for businesses aiming to enhance production efficiency and meet consumer needs effectively. These printers not only reduce setup times but also minimize waste, thereby significantly contributing to a company’s bottom line. As organizations seek to stay competitive, understanding how to leverage the capabilities of Big UV Printers will be essential in driving productivity and ensuring future success in the industry.

Investing in a big UV printer can significantly enhance production efficiency in your business by offering multiple benefits that streamline workflow and reduce operational costs. One of the primary advantages is the versatility of these printers. Capable of printing on a variety of substrates—like wood, glass, and metal—big UV printers allow businesses to diversify their offerings without needing multiple machines. This adaptability not only saves money on equipment but also enables companies to meet customer demands more effectively and creatively.

Additionally, big UV printers boast quicker drying times due to the UV curing process, which solidifies ink almost instantly. This rapid turnaround can drastically reduce bottlenecks in production, allowing for faster job completions and increased throughput. Moreover, the high-quality output provided by these printers minimizes the need for reprints, further enhancing overall efficiency. As businesses aim to optimize their operations, the incorporation of a big UV printer stands out as a strategic investment capable of delivering substantial productivity improvements and maintaining a competitive edge in the market.

When considering how to maximize production efficiency with a big UV printer, it is essential to focus on the key features that significantly enhance workflow performance. One of the most notable features is the advanced curing technology. Big UV printers utilize UV light to instantly harden the ink, allowing for faster production times and reducing the need for drying spaces. This capability not only speeds up the overall printing process but also enables printers to handle multiple jobs simultaneously without sacrificing quality.

Another critical feature is the versatility of substrate compatibility. Large UV printers can print on a variety of materials, including glass, wood, metal, and plastics, which expands the range of products a business can offer. This flexibility allows companies to diversify their services and optimize their production lines for various projects, thereby increasing revenue potential. Additionally, the high-resolution output and vibrant color reproduction of big UV printers ensure that the final products meet high-quality standards, further enhancing customer satisfaction and repeat business.

Optimizing material usage in UV printing processes is crucial for maximizing production efficiency. By carefully selecting and managing materials, businesses can significantly reduce waste and enhance their overall output. One effective strategy is to utilize advanced software that allows precise material calculations based on project specifications. This ensures that only the necessary amount of material is used for each print run, minimizing excess and reducing costs.

In addition to optimizing material selection, implementing recycling practices for leftover materials can further improve efficiency. For instance, businesses can explore the use of eco-friendly inks and substrates, which not only support sustainability but also often lead to better print quality and durability. Furthermore, with emerging technologies in the 3D printing sector, companies can benefit from innovations in material properties—such as ceramics with high strength and stability—enhancing application in various industries. By integrating these practices, businesses can achieve a more sustainable and cost-effective approach to UV printing.

When it comes to enhancing operational efficiency in your business, leveraging advanced UV printing technology can make a significant impact. One effective technique is to invest in a high-capacity UV printer that allows for versatile media options. This not only expands the range of products you can offer—such as personalized items, marketing materials, or packaging—but also streamlines your workflow by reducing the need for multiple machines. By consolidating processes into one setup, you can minimize setup times and waste, ultimately leading to increased output rates and better resource management.

Another approach is to implement a smart workflow that integrates your UV printing operations with inventory and order management systems. By automating processes such as job tracking and production scheduling, you can significantly decrease lead times. Real-time data can help you make informed decisions on resource allocation and machine utilization, ensuring that your production runs smoothly without bottlenecks. Training your staff to operate efficiently within this integrated system can further enhance productivity, making the most of the capabilities your UV printer offers. Through these techniques, businesses can achieve a remarkable transformation in their production efficiency, setting the stage for growth and increased profitability.

When considering a significant investment in a large UV printer for your business, evaluating cost-effectiveness is crucial for maximizing your return on investment (ROI). A large UV printer not only offers high-quality prints and efficiency but also serves as a versatile tool that can cater to various business needs. Integrating this technology can reduce overhead costs associated with outsourcing printing, enabling businesses to handle projects in-house while maintaining better control over production timelines and quality.

Moreover, advancements in UV light technology extend beyond printing; they are also making waves in agriculture by enhancing seed traits and boosting yields. This innovation showcases the potential of UV light applications, illustrating how businesses can leverage similar technologies to improve their operations. By maximizing printing efficiency with a large UV printer, businesses can streamline their processes, increase productivity, and ultimately see a significant boost in their profitability, similar to how agricultural innovations are transforming yield outputs. Embracing such forward-thinking technology can set a business apart in a competitive market, ensuring that every investment contributes meaningfully to overall growth.

| Parameter | Value | Notes |

|---|---|---|

| Initial Investment | $50,000 | Cost of printer and setup |

| Average Print Speed | 50 sq. ft. per hour | Speed for standard jobs |

| Average Material Cost | $2.00 per sq. ft. | Includes ink and substrate costs |

| Average Revenue per Job | $300 | Revenue from a typical job |

| Number of Jobs per Month | 40 | Estimated workload |

| Monthly Revenue | $12,000 | Revenue from jobs |

| Monthly Material Cost | $3,200 | Cost based on jobs |

| Net Monthly Profit | $8,800 | Total revenue minus costs |

| Payback Period | 5.68 months | Time to recover initial investment |