The world of printing technology has evolved significantly, with Cylinder Printers emerging as a vital component in various industries, from packaging to fine art reproduction. According to the Smithers Pira report, the global market for industrial printing, which includes Cylinder Printers, is projected to reach $20 billion by 2025, driven by increased demand for high-quality and cost-effective printing solutions. These printers are renowned for their efficiency and ability to produce vibrant, consistent outputs, making them an attractive choice for both small businesses and large enterprises looking to master their production processes. However, as the technology becomes more accessible, many beginners are eager to explore the DIY aspects of Cylinder Printers, seeking to understand the intricacies involved and the alternatives available. In this comprehensive guide, we will delve into the fundamental concepts, techniques, and tools that will empower you to master the art of Cylinder Printing, opening up a myriad of creative possibilities.

When embarking on the DIY journey of mastering cylinder printing, understanding the essential tools and materials is foundational. According to recent industry reports, the global 3D printing market is expected to reach $62 billion by 2025, illustrating a growing demand for various printing technologies, including cylinder printers. Key tools for beginners include a reliable printing filament, such as PLA or PETG, which are praised for their ease of use and versatility. Additionally, a good quality slicer software is crucial for optimizing print settings and achieving the best results.

Beyond the basic tools, having the right accessories can significantly enhance the user experience. These might include a decent build plate that provides excellent adhesion and easy removal of prints, as well as a high-quality nozzle that can handle different filament types efficiently. Investment in a basic toolkit designed for 3D printing can also streamline the process, making it easier to make adjustments and repairs on the go. With these essentials at hand, beginners can confidently dive into the world of cylinder printing and explore the endless possibilities it offers.

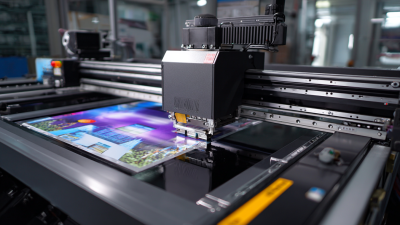

Cylinder printers, also known as rotary printers, play a crucial role in the world of printing by utilizing a unique mechanical design that allows for high-speed production of quality prints. Understanding how these printers operate starts with their fundamental components, including the rotating cylinder and the flexible printing plates. According to a report from Smithers Pira, the global market for rotary printing technology is expected to grow by 3.2% annually, highlighting the ongoing reliance on this efficient method of printing.

The mechanics behind cylinder printers involve the direct transfer of ink from the printing plate to the substrate as the cylinder rotates. This method enables continuous feed and high-volume production, essential for industries such as packaging and textiles. Interestingly, research shows that rotary printing can achieve speeds of up to 900 meters per minute, significantly outperforming traditional flatbed printers, which typically max out at around 200 meters per minute. By grasping these foundational mechanics, beginners can appreciate the advantages of cylinder printers, ultimately enhancing their DIY printing projects and understanding the broader implications in industrial applications.

Setting up your cylinder printer can seem daunting, but with a clear, step-by-step approach, beginners can achieve professional results. Start by ensuring you have a solid workspace, as cleanliness and organization are essential. According to a recent industry report, precision and attention to setup can enhance the quality of print by up to 30%. First, check that all components are included and accounted for. Follow the manufacturer's manual closely, ensuring that all mechanical parts are correctly positioned.

Tip: Before turning on the printer, run through a checklist of all parts and tools required for installation. This will save time and prevent any interruptions during the setup process. Make sure to calibrate the printer’s settings according to the material specifications you're planning to use; this is a crucial step that can make a significant difference to print quality.

Once powered, connect your printer to a reliable power source, and install the necessary software on your computer. An interesting finding from the Print Industry Association reveals that proper software configuration can increase printing efficiency by 25%. Remember to run a test print after setup, allowing you to troubleshoot any issues that may arise before starting your first project. By paying close attention to these details, you'll set a strong foundation for mastering your cylinder printer.

When mastering a cylinder printer, it's essential to equip yourself with effective troubleshooting tips to tackle common issues that may arise during the printing process. Start by ensuring that your ink supply is adequate, as low ink levels can lead to uneven prints. If you notice any discrepancies in color, double-check the ink cartridges and make sure they are properly seated and not expired.

Another frequent problem faced by beginners is alignment issues. Misalignment can cause the printed design to appear cropped or skewed. To resolve this, carefully adjust the alignment settings in your printer’s software. Additionally, regularly clean the cylinder and other components with appropriate cleaning solutions to prevent residue build-up, which can affect both print quality and the longevity of your equipment.

Lastly, listen for unusual sounds while the printer is in operation, as they can signal mechanical problems. If you hear grinding or rattling noises, it might be time to inspect the internal mechanisms for loose parts or debris. By addressing these common printing issues with the right troubleshooting techniques, you can enhance your cylinder printing experience and achieve better results.

When it comes to cylinder printing, creativity is key to transforming ordinary projects into extraordinary works of art. One effective technique is layering colors. By applying different shades in a strategic order, you can create a rich and dynamic visual effect that captures the eye. For instance, starting with a base layer of a lighter hue and gradually adding darker tones can give your prints depth and dimension.

Experimenting with transparency and mixing your inks will further enhance this multidimensionality, allowing unique patterns to emerge with each print.

Another innovative approach is incorporating textures into your cylinder printing. Utilizing various materials such as fabrics, sponges, or even textured papers can create intriguing surfaces and patterns. For example, rolling a textured sponge over your print can impart an organic, hand-crafted feel that adds character to your projects. Don't be afraid to go beyond traditional inks; experimenting with different mediums, such as metallic or fluorescent colors, can offer surprising and vibrant results.

Each technique encourages personal expression, making your cylinder printing projects not just a task but a journey into creativity.