Inquiry

Form loading...

In recent years, the manufacturing sector has witnessed a remarkable transformation driven by technological advancements, particularly with the rise of the Industrial UV Printer. According to a report by Smithers Pira, the global UV printing market is projected to reach $5.8 billion by 2024, demonstrating a compound annual growth rate (CAGR) of 10.2%. This surge can be attributed to the increasing demand for high-quality printing solutions that offer quick turnaround times and exceptional durability.

Industrial UV Printers not only enhance production efficiency but also open avenues for innovative applications across diverse industries, including packaging, textiles, and signage. As businesses strive to stay competitive in an ever-evolving market landscape, understanding the unique capabilities and applications of Industrial UV Printers becomes crucial for harnessing their full potential and driving growth in manufacturing processes.

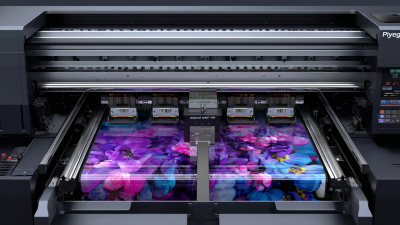

The emergence of industrial UV printers has dramatically transformed modern manufacturing processes, offering unprecedented capabilities for businesses seeking efficiency and quality. Unlike traditional printing methods, UV printers utilize ultraviolet light to cure inks instantly upon application, allowing manufacturers to streamline their operations. This technology enables the printing on a wide variety of materials, including glass, metal, wood, and plastic, which expands creative possibilities and broadens the scope for product customization.

When integrating UV printing into your manufacturing workflow, consider the following tips: First, assess the compatibility of your materials with UV printing to ensure optimal adhesion and lasting results. Experimenting with different substrates can yield innovative product designs. Second, pay attention to the maintenance of your UV printers; regular cleaning and servicing will keep them operating at peak efficiency, reducing downtime and preserving print quality. Lastly, invest in training for your staff to ensure they are proficient with this technology, maximizing its potential in your production lines.

As industrial UV printers continue to gain traction, their role in manufacturing will only grow, enhancing productivity and enabling businesses to meet the ever-changing demands of the market. Embracing this technology not only fosters innovation but also positions companies as leaders in their respective industries.

In today’s fast-paced manufacturing sector, UV printing is at the forefront of product personalization, enabling businesses to cater to the unique preferences of consumers. According to a report by Smithers Pira, the UV printing market is projected to grow to over $4.8 billion by 2025, highlighting its increasing importance in custom applications. This technology allows for the rapid production of high-quality, customized products ranging from promotional materials to personalized consumer goods, making it easier for brands to distinguish themselves in a competitive landscape.

The customization capabilities offered by industrial UV printers extend beyond simple graphical changes. They can print directly onto a wide variety of substrates, including wood, metal, glass, and plastic, thereby expanding the potential for unique product offerings. A study by Allied Market Research revealed that the demand for personalized products is expected to grow at a CAGR of 9.3% from 2020 to 2027. This surge indicates a robust market for brands willing to invest in advanced UV printing technologies that enhance product appeal through tailored designs and finishes, thus aligning with consumer desires for individuality.

In today's manufacturing landscape, sustainability has emerged as a guiding principle, shaping operational processes and product development. Industrial UV printers play a pivotal role in this shift by promoting eco-friendly practices that significantly reduce waste and energy consumption. Unlike traditional printing methods that rely on volatile organic compounds (VOCs) and lengthy drying times, UV printing employs a highly efficient curing technology. This process instantly bonds inks to various substrates using ultraviolet light, minimizing material waste and enabling immediate handling of printed items.

Moreover, UV printers are designed to use inks more efficiently, often requiring less ink compared to conventional printing techniques. This not only lowers the operational costs but also conserves resources, as manufacturers can produce high-quality prints without compromising sustainability. By integrating UV printing technology, businesses can substantially decrease their carbon footprint, aligning with global efforts to foster a more sustainable industry. As manufacturers continue to seek innovative solutions, UV printers are increasingly recognized as key players in creating a greener future for the manufacturing sector.

In today's manufacturing landscape, UV printing has emerged as a versatile solution, transforming various industries. This technology allows manufacturers to print on a wide range of materials, from textiles to industrial surfaces, revolutionizing product branding and customization. Its quick-drying feature enhances production efficiency, making it an invaluable tool for manufacturers looking to meet market demands swiftly.

A key advantage of UV printing lies in its adaptability. Industries such as signage, packaging, and textiles are harnessing this technology to create vibrant and durable prints. UV printers not only cater to conventional materials but also expand possibilities to unconventional substrates, elevating the creativity and uniqueness of products. For businesses, investing in UV printing technology could mean a significant edge over competitors by offering tailored solutions that appeal to diverse customer needs.

**Tips:**

1. Explore UV printing options that suit your specific industry requirements. This ensures that you select the right printer with features tailored to your production needs.

2. Consider partnering with a provider that can offer expert guidance on materials compatible with UV printing, maximizing your creativity while maintaining quality.

3. Stay updated on technological advancements in UV printing, as this field is continuously evolving, offering new features that can enhance your manufacturing processes.

The manufacturing landscape is undergoing a significant transformation driven by advancements in UV printing technology. As industries seek to enhance efficiency and sustainability, innovative applications of industrial UV printers are emerging. One of the most notable trends is the rapid increase in the use of UV LED technology, which offers faster curing times and lower energy consumption compared to traditional UV lamps. This shift not only streamlines production processes but also reduces the environmental impact, aligning with the growing emphasis on sustainability in manufacturing practices.

Another exciting development is the integration of smart technologies with UV printing. Manufacturers are leveraging data analytics and IoT devices to monitor printer performance and optimize material usage in real-time. This capability allows for personalized printing solutions that cater to specific customer needs while minimizing waste. Furthermore, continuous innovations in ink formulations are enabling the production of high-quality prints on various substrates, from metals to textiles. Such versatility is expanding the scope of UV printing applications, providing manufacturers with the tools to stay competitive in an ever-evolving market.