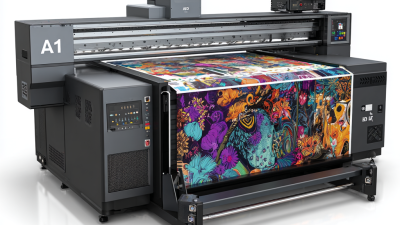

The evolution of printing technology has paved the way for innovative solutions that cater to the growing demand for customization across various industries. At the forefront of this transformation is the A1 UV Printer, a game-changer that combines versatility and precision to meet the diverse needs of modern businesses. As we explore the future of A1 UV Printers, we will delve into the myriad possibilities they offer for personalized printing, from intricate designs to unique materials. The significance of customization in enhancing brand identity and engaging consumers cannot be overstated, and A1 UV Printers are uniquely positioned to lead this charge. With their ability to print on an array of surfaces and deliver high-quality results, these printers are not just tools but catalysts for innovation. In this discussion, we will examine the potential advancements and applications of A1 UV Printers that could reshape the printing landscape, enabling businesses to push the boundaries of creativity and personalization like never before.

The evolution of printing technology has paved the way for innovative solutions that cater to the growing demand for customization across various industries. At the forefront of this transformation is the A1 UV Printer, a game-changer that combines versatility and precision to meet the diverse needs of modern businesses. As we explore the future of A1 UV Printers, we will delve into the myriad possibilities they offer for personalized printing, from intricate designs to unique materials. The significance of customization in enhancing brand identity and engaging consumers cannot be overstated, and A1 UV Printers are uniquely positioned to lead this charge. With their ability to print on an array of surfaces and deliver high-quality results, these printers are not just tools but catalysts for innovation. In this discussion, we will examine the potential advancements and applications of A1 UV Printers that could reshape the printing landscape, enabling businesses to push the boundaries of creativity and personalization like never before.

The evolution of A1 UV printers has significantly enhanced their customization capabilities, positioning them as essential tools across various industries. Recent advancements showcase a trend towards more innovative and flexible applications, enabling users to create highly personalized products. According to industry reports, the global UV printer market is projected to reach $4.8 billion by 2025, with a compound annual growth rate (CAGR) of 10.5%. This growth is largely driven by the demand for customized printing solutions in sectors such as electronics, packaging, and textiles.

The introduction of advanced features, such as tactile controls and waterproof membrane switches, exemplifies the shift toward customization. For instance, the new manufacturing techniques for microneedle molds utilizing desktop SLA 3D printers provide a cost-effective solution, allowing businesses to tailor products to specific requirements without the need for large investments. Such innovations not only enhance the functionality of UV printing but also facilitate the development of unique design features that cater to consumer preferences. As customization becomes paramount, A1 UV printers are set to play a pivotal role in transforming product personalization in the coming years.

The UV printing technology has been rapidly evolving, highlighting significant trends in customization solutions across various markets. With the ability to cure resin instantly upon exposure to ultraviolet light, UV printers are at the forefront of facilitating bespoke applications that meet the increasing demand for personalized products. As consumer preferences shift towards customization, industries such as wallpaper printing and commercial printing are seeing a surge in the use of digital printing technologies that allow for greater flexibility and creativity.

September unveiled the 19th Zhuhai International Office Exhibition, showcasing over 400 exhibitors that illustrated the growing landscape of the office equipment sector. This event not only emphasizes the importance of high-quality UV printing solutions but also the innovative ways companies can leverage these technologies to respond to market needs. As we look ahead, it is clear that the integration of customization and innovation in UV printing will continue to define the market, driving growth and inspiring new applications across industries.

As environmental awareness grows, the printing industry is increasingly focusing on sustainable practices. A1 UV printers stand at the forefront of this movement, offering significant advantages in material use and waste reduction. Unlike traditional printers that often rely on eco-harmful inks and chemicals, A1 UV printers utilize UV-cured inks, which emit fewer volatile organic compounds (VOCs) and are generally safer for the environment. This technology not only enhances print quality but also minimizes the ecological footprint, aligning with global sustainability goals.

Moreover, A1 UV printers are highly versatile and can print on various substrates, including unconventional materials like glass, metal, and wood. This capability reduces the need for multiple printing processes and the associated waste, further promoting sustainability. By allowing for greater customization without compromising on environmental standards, A1 UV printers empower businesses to meet customer demands while prioritizing responsible material use. This combination of innovation and sustainability positions A1 UV printers as a game-changer in the quest for environmentally friendly printing solutions.

| Dimension | Description | Impact on Sustainability | Material Usage |

|---|---|---|---|

| Customization Options | Variety of colors, textures, and finishes available for printing. | Reduces waste by allowing exact color matching and customer-specific designs. | Utilizes non-toxic inks and materials when possible. |

| Ink Technology | UV-cured inks that are durable and vibrant. | Lower VOC emissions contribute to a safer environment. | Efficient ink usage leads to less waste and higher output. |

| Speed and Efficiency | Rapid production speeds allow for faster turnaround times. | Minimizes energy consumption per unit produced. | Supports both small and large production runs without excess material usage. |

| Versatile Materials | Ability to print on a wide range of substrates, including wood, glass, and metal. | Encourages recycling and upcycling of materials. | Facilitates the use of biodegradable and eco-friendly materials. |

| Innovative Applications | New techniques such as 3D printing and textured printing. | Promotes longer-lasting products that reduce overall consumption. | Efficient use of existing materials tailored to specific products. |

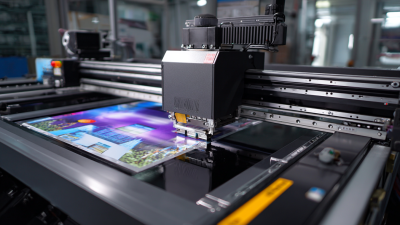

The future of A1 UV printers is poised for significant advancements in both quality and efficiency, driven by ongoing innovations in printing technology and materials. Recent industry reports indicate a substantial increase in demand for high-quality printing solutions, particularly in the customization sector, where businesses seek tailored products to enhance user experience. For instance, a recent review highlighted the intersection of advanced polymer composites with 3D printing technology, illustrating how such materials can improve the durability and aesthetic appeal of printed goods. This trend is particularly relevant as brands look to differentiate their offerings through unique designs and functionalities.

Moreover, advancements in digital printing technology, such as enhancements in color-conversion displays, are set to influence the capabilities of UV printers. Enhanced color quality is becoming a critical factor in meeting consumer expectations, as reports indicate a growing appetite for vibrant, high-resolution outputs in packaging and labeling industries. With events like Labelexpo Southeast Asia showcasing cutting-edge machinery and technologies, the A1 UV printer market is likely to see innovative solutions that not only raise the bar for print quality but also streamline production processes, ultimately enhancing efficiency and reducing turnaround times for businesses. The integration of such technologies into A1 UV printers will redefine customization possibilities, making high-quality, bespoke prints more accessible than ever.

This chart illustrates the projected advancements in quality and efficiency metrics of A1 UV printers over the next five years, focusing on key innovation areas such as speed, color accuracy, and material versatility.

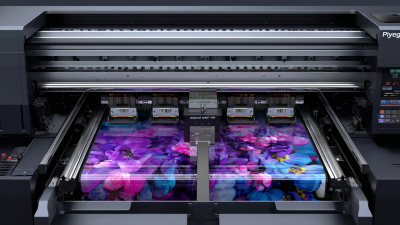

The customization capabilities of A1 UV printers have been showcased through a variety of successful projects across different industries. For instance, a notable case study comes from a signage company that utilized A1 UV printing technology to create personalized displays for a local event. By leveraging the printer’s ability to handle large formats and intricate designs, they were able to produce vibrant, custom graphics that effectively attracted attendees’ attention. This project not only highlighted the printer's versatility but also demonstrated how customized solutions can enhance brand visibility in competitive environments.

Another impressive project involved a fashion apparel business that integrated A1 UV printers to design unique textile patterns. By creating one-off prints for individual customers, the brand embraced a made-to-order philosophy, allowing customers to participate in the design process. The A1 UV printer's precision and ability to print on various materials offered the fashion industry an innovative avenue for creativity, enabling dynamic designs that stood out in the market. Such case studies exemplify the transformative potential of A1 UV printers in customization, paving the way for innovative practices in various sectors.