Inquiry

Form loading...

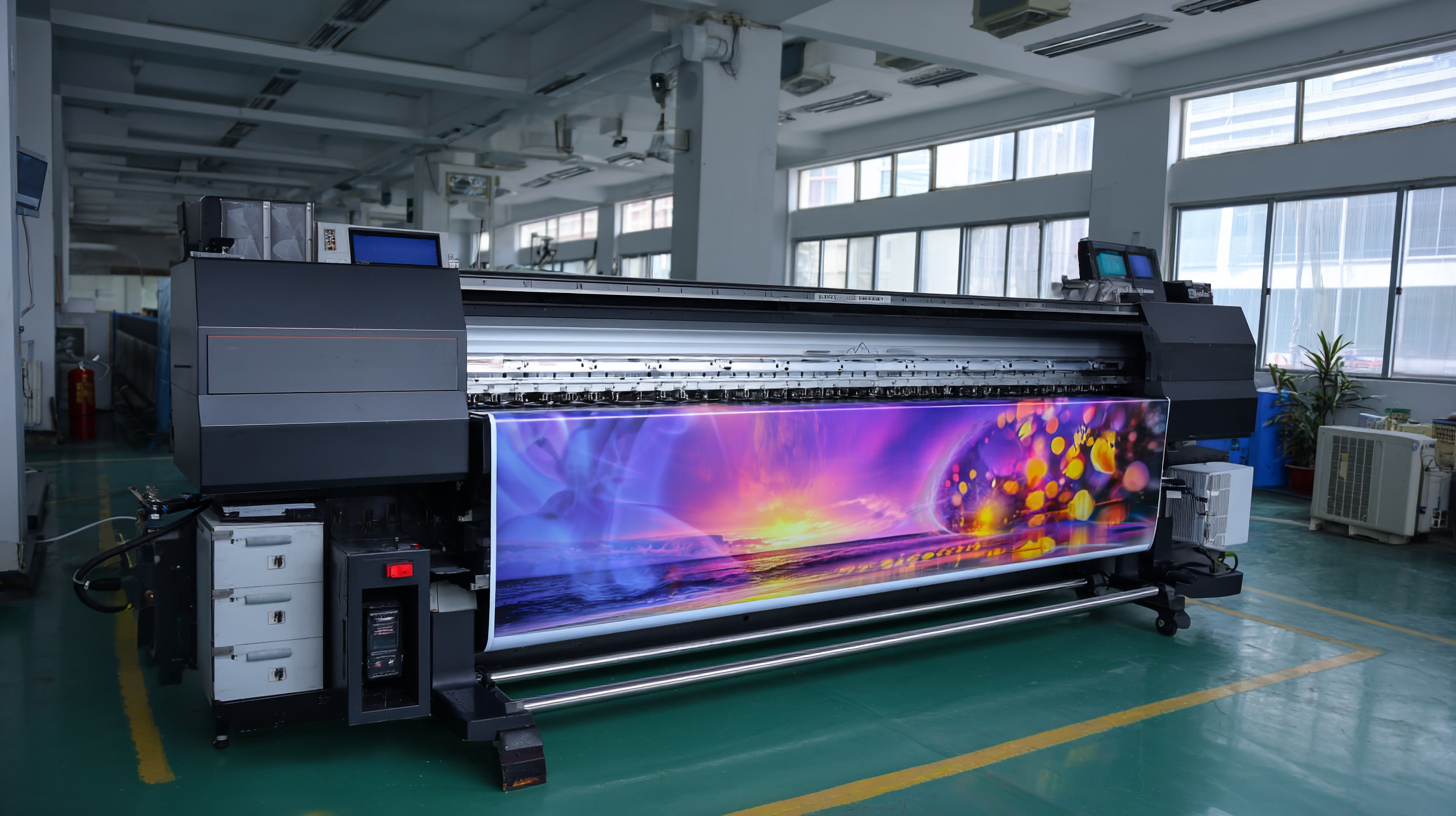

In the rapidly evolving landscape of digital printing, selecting the right equipment is crucial for achieving optimal results and maintaining competitive advantage. The demand for high-quality printing solutions has surged, with the global digital printing market projected to reach $29 billion by 2026, according to recent industry reports. Among the various options, the 4060 UV printer stands out due to its versatility and capacity to print on a wide variety of substrates. This printer is particularly favored for its ability to produce vibrant graphics and detailed imagery, making it suitable for both commercial and creative applications. As businesses increasingly seek sustainable print solutions, understanding the key features and capabilities of the 4060 UV printer can significantly impact productivity and output quality. This guide aims to provide insights and practical tips for choosing the best 4060 UV printer, ensuring that you make an informed investment tailored to your specific needs.

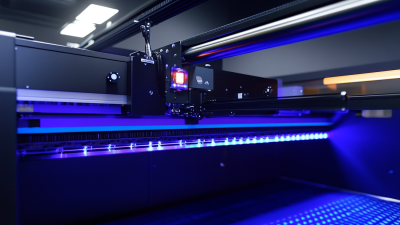

UV printing technology offers several distinct advantages, making it a highly sought-after option for various applications. One of the primary benefits is its versatility, as UV printers can handle a wide range of substrates, including plastics, wood, and metal. This capability is particularly beneficial for industries looking to produce high-quality prints on diverse materials. Additionally, UV inks cure quickly when exposed to UV light, which not only speeds up the printing process but also results in vibrant colors and sharp details. This rapid curing process minimizes the risk of smudging and allows for immediate handling of printed materials.

The advancements in UV printing technology have also led to innovations such as LED curing, which represents a significant improvement over traditional curing methods. LED curing is known for providing better results, especially with challenging inks like white and densely pigmented options. This technology not only enhances print quality but is also more energy-efficient, making it an environmentally friendly choice. As industries continue to explore the potential of UV printing, understanding these benefits can guide businesses in selecting the right printer to meet their specific needs and capitalize on the evolving market opportunities.

This bar chart compares various performance metrics for the 4060 UV printer, highlighting the speed, print quality, ink cost, maintenance cost, and durability advantages of UV printing technology.

When selecting a 4060 UV printer, there are several key features that can significantly impact performance and output quality. Firstly, look for print resolution capabilities; a printer that offers a minimum of 1440 dpi ensures crisp, high-quality images, which is essential for businesses involved in graphics, signage, or customized items. According to the Specialty Graphic Imaging Association (SGIA), printers with higher resolutions cater to a growing demand for detailed and vibrant print outputs, which can be a decisive factor in competitive markets.

Additionally, consider the versatility of media handling. A 4060 UV printer that supports various substrates—from rigid materials like wood and glass to flexible films—can add significant value to your business offerings. A report by Smithers Pira indicates that the market for UV printing is expected to grow by 7% annually, highlighting the need for printers that can adapt to different job requirements. Furthermore, evaluating the curing technology is crucial; look for printers that feature integrated UV LED lights, which can enhance speed, reduce energy consumption, and lower the overall operational costs. This technology can set a printer apart in terms of efficiency and print durability.

When evaluating the market for 4060 UV printers, it’s crucial to compare different brands to identify which model best fits your specific printing needs. According to a recent report by Smithers Pira, the global market for UV printing is expected to reach $6.9 billion by 2025, largely driven by advancements in printing technology and increasing demand for high-quality outputs. Leading brands in the 4060 UV segment, such as Mimaki, Roland, and Epson, offer varying features that cater to different applications, from signage to custom packaging.

Mimaki’s UJF-4062, for instance, is renowned for its exceptional print resolution and versatility, allowing users to print on a wide range of substrates. In contrast, Roland's VersaUV LEF-20 stands out for its user-friendly interface and advanced UV LED technology, which results in reduced energy consumption and faster curing times. Comparing these features based on your production requirements can significantly influence your overall operational efficiency and cost-effectiveness, particularly in an industry where precision and speed are paramount. Understanding these distinctions can empower businesses to make informed purchasing decisions in the expansive world of UV printing.

Maintaining your 4060 UV printer is crucial for ensuring longevity and consistent performance. According to the 2022 Global Digital Printing Market Report, proper maintenance can extend the lifespan of a UV printer by 30% or more, which is significant given the investment involved. Regular cleaning and using high-quality inks are essential practices that can prevent common printing issues and enhance the output quality.

Tips for maintaining your 4060 UV printer include regularly checking the print heads for clogs, which can significantly affect print quality. Conduct a thorough cleaning routine every two weeks to remove dust and debris, and run maintenance cycles as recommended by the manufacturer. Additionally, ensure that your UV printer operates in an optimal environment; keeping it in a controlled setting can prevent overheating and reduce wear on components.

Another vital tip is to monitor the ink levels and replace cartridges promptly. Data from industry sources show that printers with low ink levels can experience print inconsistencies, leading to wasted material and increased costs. By investing time in maintenance and following these tips, you can ensure that your 4060 UV printer remains in top shape for years to come.

The 4060 UV printer has gained significant traction across various industries due to its versatility and high-quality output. According to a report by Smithers Pira, the global digital printing market is predicted to reach $283 billion by 2024, with UV printing technology playing a crucial role in this growth. The ability to print on a wide range of substrates while maintaining precision has opened up numerous applications. For instance, in the packaging industry, 4060 UV printers are increasingly used for producing labels, boxes, and flexible packaging that require vibrant colors and durability.

Additionally, the promotional products sector is leveraging 4060 UV printers for customized items such as signage, promotional displays, and corporate gifts. A survey conducted by MarketsandMarkets indicates that personalized products are expected to grow at a CAGR of 10.6% from 2021 to 2026, highlighting the increasing demand for unique, customized designs. Furthermore, in the decor and signage industry, 4060 UV printers are becoming essential for creating eye-catching displays and wall art, allowing businesses to stand out in a competitive market. The ability to print on materials like glass, metal, and wood further enhances their appeal, making 4060 UV printers a valuable asset for various creative applications.

| Application Area | Industry | Common Materials | Advantages |

|---|---|---|---|

| Signage | Advertising | Acrylic, PVC, Foam Board | High durability, vibrant colors |

| Packaging | Food & Beverage | Cardboard, Plastics | Custom designs, quick turnaround |

| Promotional Items | Retail | Metal, Wood, Glass | Unique textures, personalization options |

| Decorative Printing | Interior Design | Wallpaper, Fabric | Custom designs, high-quality finish |

| Labeling | Manufacturing | Vinyl, Paper | Fast production, high detail |