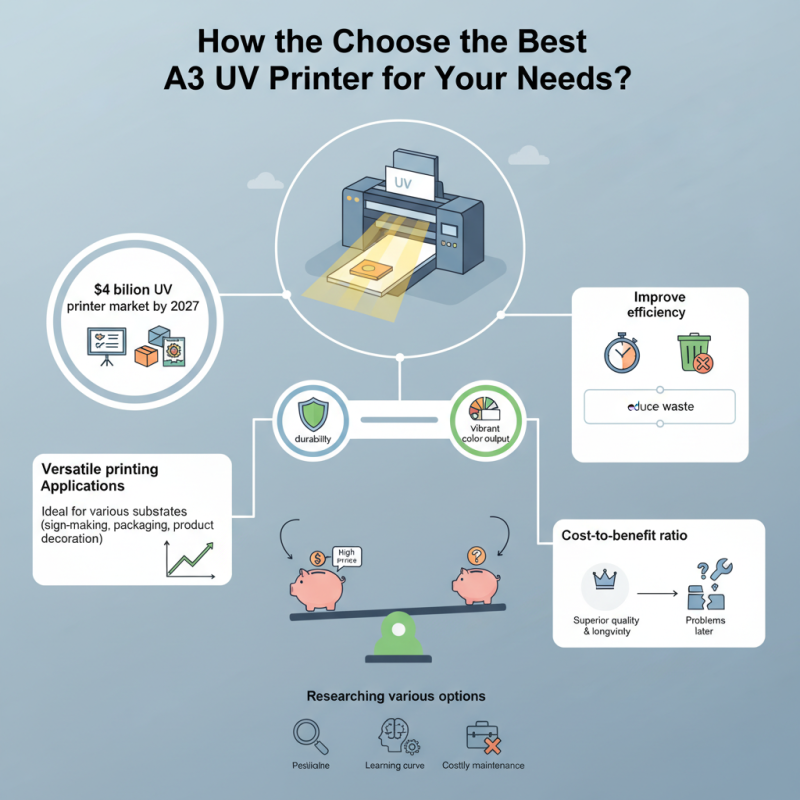

Choosing the best A3 UV printer is crucial for businesses seeking high-quality printing solutions. The global UV printer market is expected to reach $4 billion by 2027, driven by rising demand for versatile printing applications. A3 UV printers play a pivotal role in this growth. They are ideal for various substrates, making them popular in sign-making, packaging, and product decoration.

When considering an A3 UV printer, it is essential to evaluate specific needs and capabilities. Look for printers that offer durability and vibrant color output. The right choice can improve efficiency and reduce waste. However, not every model is perfect. Some units may have a learning curve or require costly maintenance. Researching various options can help identify these issues early.

Additionally, keep in mind the cost-to-benefit ratio. While some A3 UV printers come with a high price tag, they may provide superior quality and longevity. Lower-cost options might save money initially but could lead to problems later. Balancing these factors is key in finding the perfect A3 UV printer tailored to your business.

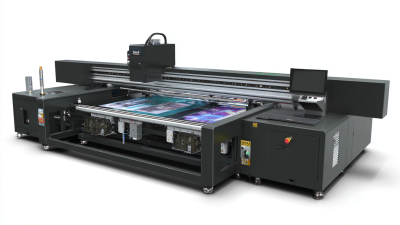

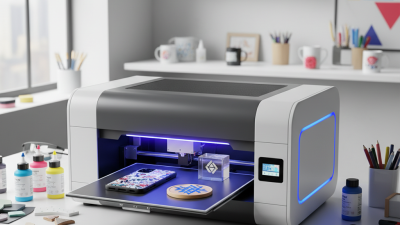

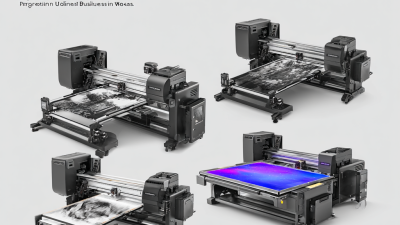

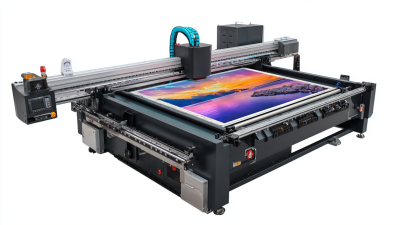

When selecting an A3 UV printer, it's vital to understand the types available in the market. There are flatbed printers, known for their versatility and ability to print on various surfaces. These machines excel at printing on rigid materials such as wood, glass, and metal. Many users appreciate their high-quality output. However, the price point for flatbeds can be quite high, and maintenance may be complex.

Another option is roll-to-roll printers. These are ideal for creating banners and signage. They handle flexible materials, like vinyl and fabric, with ease. However, their limitation is the lack of support for rigid substrates. Users often find themselves needing both types of printers for different applications. This duality can lead to increased costs and space usage.

The choice between printers depends on your printing needs. Some users might feel overwhelmed by the specifications. Evaluating the intended use is essential, yet it can lead to indecisiveness. Understanding these types will help streamline your decision-making process. Keep in mind that a printer is not just a tool; it's an investment in your business's future.

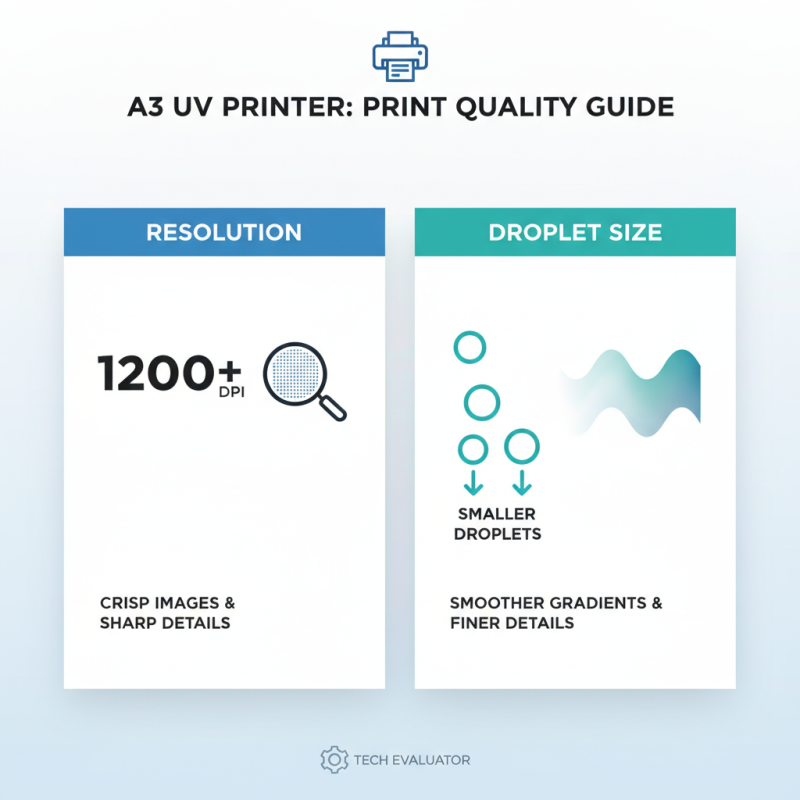

Choosing the right A3 UV printer can be daunting. Evaluating print quality is essential. Start by considering the resolution. Look for a printer that offers at least 1200 dpi for crisp images. This will ensure your prints are sharp and detailed. A printer's droplet size also matters. Smaller droplets create smoother gradients and finer details.

Next, examine color accuracy. Check for printers that can reproduce a wide color gamut. This is crucial for vibrant images. Additionally, consider the types of materials the printer can handle. Flexibility to print on various surfaces is a significant advantage.

The curing process is another key element. LED UV curing is often faster and can enhance print durability. However, it may also add extra costs. Be aware of the maintenance requirements too. Regular upkeep can affect quality. Make sure you are prepared for this, as neglect can lead to subpar prints. Reflect on these features carefully to avoid potential regret in your decision.

When budgeting for an A3 UV printer, it's essential to weigh cost against features. A lower-priced model may seem appealing, but it might lack the advanced functionalities crucial for specific projects. Think about the materials you plan to print on. Some printers excel with rigid substrates, while others perform better with flexible materials. Don’t overlook this detail; it can greatly impact your final results.

Features like print resolution, speed, and color accuracy often dictate a printer’s price. A high-resolution printer may cost more upfront, but the quality it delivers can save you money and time in the long run. Consider your production needs. If you require high volume, investing in a faster model is wise. Yet, these machines typically have higher price tags.

Don't forget maintenance costs. Some affordable models may have hidden expenses, like replacement parts and ink. Even if a printer is budget-friendly, those ongoing costs can add up quickly. Reflect on how you'll use the printer. Will you prioritize high-quality prints, or is speed your main concern? Knowing your needs will help you make the right choices and avoid potential regrets.

When choosing an A3 UV printer, ease of use and maintenance are key factors.

A user-friendly interface makes a significant difference. Look for printers with intuitive control panels. It saves time and reduces frustration.

Also, consider the loading process. Quick and efficient media loading can enhance your workflow.

Maintenance is crucial for long-term performance. Regular cleaning is necessary to prevent ink buildup. A printer with automated cleaning cycles simplifies this task. Check how easy it is to access parts that require regular maintenance. Simplified access can save precious time.

Tips:

Always read user reviews to understand real experiences. Some users may highlight maintenance pitfalls, which can guide your choice. Additionally, consider training options provided by the manufacturer. Training can ease the learning curve significantly.

A3 UV printers are versatile machines that can handle a variety of materials. From rigid substrates to flexible ones, the compatibility of these printers is impressive. According to a recent industry report, 70% of businesses using A3 UV printers cite the ability to print on multiple surfaces as a significant advantage. Common materials include plastics, wood, glass, and metal. Each of these surfaces allows for unique applications, and understanding how to utilize them is crucial.

However, not all materials yield the same results. For example, some plastics may warp or not adhere properly. This often leads to wasted materials and time, which can be frustrating. Glass, while visually stunning, requires careful handling and specific inks to ensure durability. The need for testing different ink formulations and curing processes can’t be ignored.

Choosing the right material can significantly impact the final product's quality. Reports suggest that 45% of users faced challenges with adhesion or fading when printing on certain materials. This reflects the importance of careful selection and understanding the properties of each substrate. Knowing the strengths and weaknesses of each material can improve your printing outcomes.