Inquiry

Form loading...

In today's rapidly evolving printing industry, the choice between DTF Printer and UV Printer has become crucial for businesses aiming to enhance their operational efficiency and expand their market reach. Understanding the distinct advantages of each technology can empower business owners to make informed decisions that align with their growth strategies. DTF printers are known for their versatility, enabling the printing of high-quality designs on a variety of fabric types, while UV printers offer the ability to print on diverse surfaces, including plastics, glass, and metals, with remarkable durability and vibrancy.

As competition intensifies in the custom printing sector, entrepreneurs must consider how investing in either DTF printer or UV printer will impact their production capabilities and profitability. An effective approach to selecting the right printer involves evaluating the specific needs of the target market, production volume, and the types of products being offered. This article will guide you through the essential considerations and benefits of DTF printer and UV printer, helping you to unlock new opportunities for innovation and customer satisfaction in your business.

The custom apparel market is witnessing significant growth, with the DTF (Direct to Film) printer emerging as a critical player in this evolution. DTF technology enables high-quality prints on a variety of fabrics, making it ideal for custom t-shirt production. The increasing demand for personalized apparel, coupled with advancements in printing technologies, is paving the way for businesses to capitalize on this trend. As the global custom t-shirt printing market is projected to expand significantly, investing in DTF printers can give companies a competitive edge by enhancing their product offerings.

Tips for leveraging DTF printing include choosing high-quality films and inks to ensure durability and vibrant colors. Additionally, businesses should market their unique designs effectively to attract a broad audience. Automating the printing process can also streamline operations, allowing for faster turnaround times and greater output, which are essential for catering to a growing customer base.

As the custom t-shirt printing market continues to flourish, the integration of DTF technology not only enhances product quality but also fosters brand loyalty. Entrepreneurs venturing into this space should remain adaptable, continuously exploring new design trends and consumer preferences to stay ahead in a rapidly evolving market.

This chart illustrates the market growth percentage of DTF and UV printers from 2020 to 2023. The significant increase in DTF printer usage over the years highlights its critical role in the custom apparel market growth.

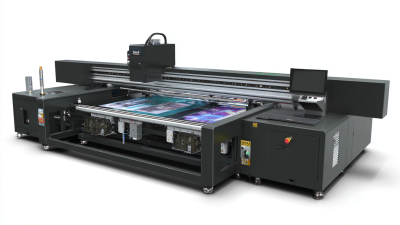

UV printers have emerged as a pivotal technology for businesses seeking to enhance their product offerings and improve operational efficiency. Their versatility is one of the key advantages that makes them invaluable across various industries. From promotional products to customized packaging, UV printers can produce vibrant prints on a wide range of materials, including plastics, metals, glass, and wood, which opens up endless possibilities for design and creativity.

This capability allows businesses to stand out in a competitive market by providing unique, high-quality products that meet the specific needs of their customers.

Moreover, the speed and efficiency of UV printing contribute significantly to business productivity. The instant curing process of UV inks means that prints are ready for handling right away, reducing turnaround times and allowing businesses to meet tight deadlines. Additionally, the durability of UV prints, which are resistant to fading and scratching, ensures that products maintain their quality over time, establishing trust with customers. By leveraging the versatility and efficiency of UV printers, businesses can not only enhance their offerings but also position themselves for sustainable growth in a rapidly evolving market.

When it comes to selecting a printing solution for your business, understanding the cost-effectiveness of DTF (Direct to Film) and UV (Ultraviolet) printers is crucial. Both options offer unique benefits and challenges, but choosing the right one can significantly affect your investment returns. DTF printers are typically more affordable upfront, making them an attractive option for startups or small businesses looking to limit expenses. However, operational costs and material prices should also be considered when calculating the long-term benefits.

Tip: Evaluate the type of products you plan to offer. If your business focuses on garment printing, DTF might yield better results due to its flexibility and material compatibility. Conversely, if you're targeting hard surfaces like metal or glass, UV printing could provide superior durability and vibrant finishes.

Additionally, while DTF printers might generally save you money initially, UV printers are known for their rapid printing speeds and the ability to produce high-quality, long-lasting prints. This can lead to increased customer satisfaction and repeat business, which can ultimately enhance your profitability.

Tip: Analyze potential market trends to gauge which printing technology aligns with your strategic goals. Conducting a cost-benefit analysis will help you understand how each printer can grow with your business, allowing you to make informed decisions for sustainable growth.

| Printing Technology | Initial Investment | Operating Costs | Revenue Per Job | ROI (Return on Investment) |

|---|---|---|---|---|

| DTF Printer | $10,000 | $0.50 per print | $5.00 | 300% in 12 months |

| UV Printer | $15,000 | $1.00 per print | $7.00 | 200% in 12 months |

| Comparison Summary | N/A | DTF is more cost-effective | Higher revenue with DTF | DTF offers better ROI |

In today's competitive landscape, businesses must leverage advanced printing technologies to maintain a distinct edge. The photo printing and merchandise market in Europe is projected to grow significantly, from $3.08 billion in 2025 to $4.92 billion by 2032, driven by a compound annual growth rate of 6.92%. This trend underscores the importance of selecting the right printing methods, such as DTF or UV printing, to tap into emerging market opportunities and meet customer demands.

Tips: Consider investing in a DTF printer for its versatility and cost-effectiveness when producing custom apparel. Alternatively, a UV printer may be ideal for businesses focusing on high-quality, durable prints on various materials, meeting the needs of the expanding merchandise market. Keeping abreast of technological advancements not only caters to current consumer preferences but also positions your business for future growth by enhancing production efficiency and print quality.

As industries shift towards innovative solutions, organizations involved in commercial aviation and space exploration are also witnessing market expansions. The advanced engineering materials market is expected to evolve rapidly, creating benefits for businesses that can integrate advanced printing technologies into their production processes. Embracing these trends now will enable businesses to stay competitive and responsive to changing market demands.

Choosing between a DTF (Direct to Film) printer and a UV (Ultraviolet) printer is a vital decision for businesses aiming to enhance product quality and customer satisfaction. DTF printers are celebrated for their ability to produce vibrant colors and intricate designs on a variety of fabrics, making them an excellent choice for apparel printing.

According to a recent report by Smithers Pira, the digital textile printing market is projected to see a compound annual growth rate (CAGR) of 20% through 2025, highlighting the growing demand for high-quality printing solutions.

Conversely, UV printers offer versatility, allowing businesses to print on different substrates such as plastic, wood, and metal while providing excellent durability and resistance to fading. Research from Pira International indicates that UV printing has transformed packaging and promotional materials, with a significant segment expected to grow by 15% annually. This adaptability not only enhances product quality but also expands market reach, responding to diverse customer needs effectively.

Tips: When selecting between DTF and UV printers, assess your target market's preferences and the materials you wish to print on. Investigate customer feedback on product durability and satisfaction to guide your choice. Additionally, consider investing in a dual-system setup for ultimate versatility and responsiveness to market trends.