Choosing the right 6090 UV Flatbed Printer can significantly impact your business. Experts in the industry emphasize the importance of understanding your specific needs. John Smith, a renowned printing expert, stated, "The right printer is crucial for maximizing efficiency and quality."

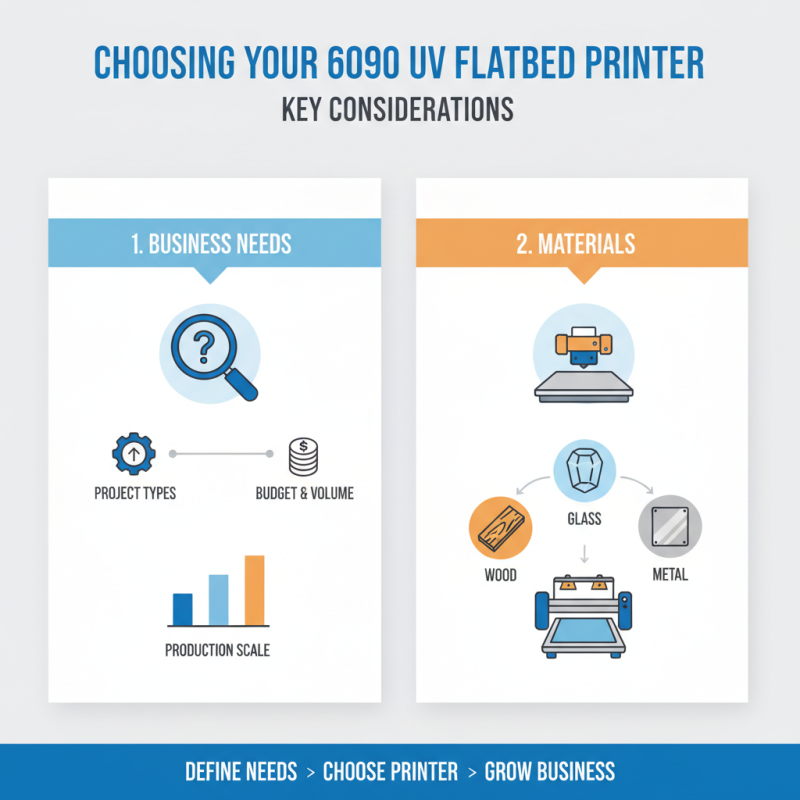

When selecting a 6090 UV Flatbed Printer, consider various factors. First, assess your materials. Some printers excel with specific substrates. This could influence your final product's texture and durability. Additionally, think about production capacity. A printer that is too slow can hinder your workflow.

Reflect on your budget as well. High-quality printers can be costly. However, cheaper options may lead to more frequent repairs. Investing in a reliable model is vital. Ultimately, take the time to research and weigh your choices. The perfect 6090 UV Flatbed Printer should align with your business objectives.

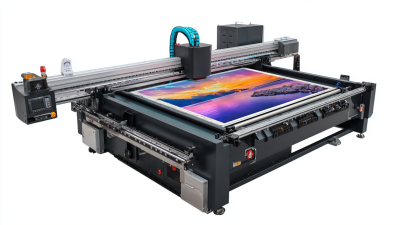

Understanding the basics of 6090 UV flatbed printers is crucial for anyone looking to invest in this technology. These printers utilize ultraviolet light to cure or dry ink as it's printed. They are versatile and can print on various materials. According to a recent market report, the demand for UV flatbed printers is expected to grow by over 10% annually.

When considering a 6090 model, you should look closely at the print resolution. Higher resolutions provide better detail but may slow down production speeds. Additionally, pay attention to the material compatibility. Not all printers can handle all surfaces well. Challenges with adhesion on certain materials may arise, leading to waste.

Another factor to consider is operational ease. User-friendly software can make a significant difference. Complex interfaces can hinder productivity. Choosing a printer that balances features and usability often requires reflection and trial. The investment should align with your business goals. Unexpected costs can emerge from maintenance or replacement parts. Understanding these basics will prepare you for informed decisions in your business.

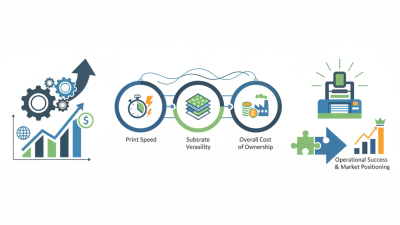

When choosing a 6090 UV flatbed printer, consider the printing speed. Faster printers save time. However, a speedy machine might compromise the quality. Balance speed and resolution carefully for optimal results. Avoid machines that promise high speeds but have poor reviews on quality.

Next, look at the printing area. The 6090 model should accommodate your typical project size. A limited area can restrict your creativity. Ensure it fits the common materials you use. Some printers may excel in printing on rigid surfaces but struggle with flexible materials.

Finally, evaluate the software compatibility. A user-friendly interface is essential. Complicated software could slow down your workflow. Check if the printer's software integrates well with your existing systems. This can save time and reduce frustration. Don't overlook any of these key features. They can make a significant difference in your daily operations.

Choosing the right 6090 UV flatbed printer starts with understanding your business needs. Consider the type of materials you plan to print on. Different projects require different substrates. Think about whether you’ll be printing on wood, glass, or metal. This variety will affect your printer selection.

Next, assess your printing volume requirements. Are you running a small operation with a few prints daily? Or do you require high-volume production? If the latter is true, you might need a more robust machine. High-speed capabilities can become essential. However, remember that higher capacity machines may come with trade-offs, like increased costs or complexity.

It’s also crucial to evaluate the workflow. Do you have the space for a larger printer? Can your current setup accommodate one? Juggling these elements can be difficult. Understanding your needs allows you to make better decisions. Balancing affordability with functionality is not always easy, but it is vital for growth. You’ll need to reflect on the long-term impact of your choice.

When choosing a 6090 UV flatbed printer, comparing brands and models is essential. Each brand offers unique features that can significantly impact your business. Some may focus on speed, while others prioritize print quality. Understanding these differences helps in making an informed choice.

Tips: Look for user reviews and feedback. Real-world experiences often highlight strengths and weaknesses. Consider visiting trade shows to see printers in action. It’s a chance to compare print quality directly.

Don’t overlook the importance of support services. Some brands provide better customer support than others. This can be crucial when issues arise. Also, evaluate the availability of replacement parts. Limited availability can lead to costly downtimes.

Be mindful of your specific needs. What works for one business may not work for another. Think about the types of materials you will be printing on. Test prints on your materials can uncover potential issues. Always keep an open mind to change as technology advances.

When choosing a 6090 UV flatbed printer, assessing the budget and total cost of ownership (TCO) is crucial. The initial purchasing price is just the beginning. According to a recent industry report, maintenance costs can account for 15-20% of the TCO. This includes routine servicing and potential repairs. Small business owners often overlook these figures. They get dazzled by upfront savings, only to face higher expenses later.

Consider consumables like ink and materials. Research shows that consumables can represent 30-40% of the annual running costs. The type of media used can also influence these expenses. Some substrates require specialized inks, which can inflate costs unexpectedly. Additionally, training staff on new machinery incurs hidden costs too. Not accounting for this can leave businesses unprepared financially.

Assessing potential downtimes is another critical factor. Delays can stem from both maintenance and unexpected breakdowns. Irregular operations may result in significant revenue losses. A study highlighted that businesses can lose up to 25% of their productivity during these periods. This reality can challenge the sustainability of business models built around the printer. Understanding the TCO fully empowers savvy business owners to make informed, strategic decisions.

| Feature | Description | Estimated Cost (USD) |

|---|---|---|

| Initial Purchase Price | Cost of acquiring the printer | $15,000 |

| Maintenance Costs | Annual maintenance and service | $1,200 |

| Ink Costs | Cost of ink per month | $300 |

| Electricity Costs | Monthly electricity consumption | $150 |

| Space Requirements | Space needed for installation | 50 sq. ft. |

| Operational Training | Cost for staff training on operation | $1,000 |

| Total Cost of Ownership (5 Years) | Sum of all costs over 5 years | $27,000 |