In the competitive world of printing, choosing the right equipment is crucial. The 2513 UV Printer stands out for its versatility and quality. Industry reports show that UV printing technology has experienced significant growth, projected to expand by over 7% annually through 2025. With this printer, businesses can achieve vibrant colors and precise detail.

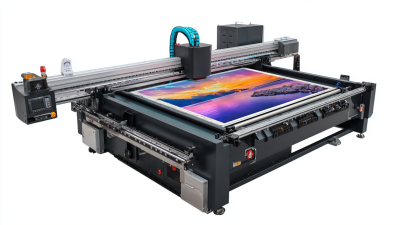

The 2513 UV Printer excels in producing high-resolution prints on various materials. Its ability to print on rigid surfaces opens new doors for creative projects. Businesses benefit from fast drying times, enhancing productivity. However, some users report initial setup challenges. Understanding these issues can lead to better results.

Moreover, the 2513 UV Printer is known for its eco-friendly capabilities. It uses UV-cured inks, reducing waste and harmful emissions. Yet, finding the right balance between quality and sustainability remains a concern. The right choice of equipment can make a substantial difference in output and environmental impact. Investing in the 2513 UV Printer might be the key to meeting your printing needs effectively.

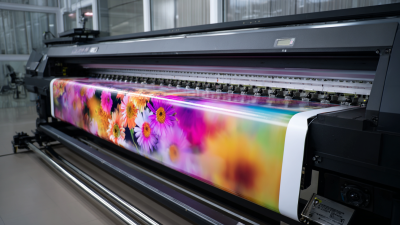

The 2513 UV printer is gaining traction across various industries. Its versatility is a key factor in this trend. Whether in signage, packaging, or ceramics, it meets diverse printing needs. The ability to print on different surfaces is impressive. Materials like glass, wood, and metal can all be used effectively. This adaptability leads to more creative projects and unique products.

One notable benefit of the 2513 UV printer is its quick drying time. This feature allows for faster production without sacrificing quality. Businesses can handle more jobs per day. The vibrant colors produced are also a major plus. They can catch a customer's eye instantly. This is critical in competitive markets.

Tips: Make sure to maintain the printer regularly. This ensures optimal performance. Experiment with different materials to find the best fit for your needs. Understanding the machine's capabilities can lead to exciting innovations. The learning curve might be tough, but it’s worth it. Embrace the challenges and watch your business grow.

When selecting a UV printer, the 2513 model stands out due to its impressive features. This printer delivers exceptional print quality. With its advanced UV curing technology, prints are vibrant and detailed. You can achieve precise designs on various surfaces. This flexibility is crucial for businesses needing versatility.

One key aspect is the printer's speed. The 2513 UV printer operates swiftly, increasing productivity. However, users might find the initial setup challenging. Take your time to read the instructions carefully. Here’s a tip: practice on different materials to find the best settings.

Color accuracy is another notable feature. The 2513 uses a wide color gamut, enhancing your artwork significantly. Colors remain consistent even under various lighting conditions. Yet, it’s essential to calibrate regularly. This ensures the colors stay true to your expectations. Remember to keep the printer clean to maintain its performance. Regular maintenance helps avoid potential issues down the line.

| Feature | Description | Benefit |

|---|---|---|

| High Resolution | Offers prints up to 1200 dpi | Produces sharp and detailed images for high-quality outputs |

| Versatile Media Compatibility | Compatible with various materials, including plastics, glass, and wood | Allows for diverse applications across different industries |

| Eco-Friendly Inks | Utilizes UV-curable inks that are safe for the environment | Minimizes environmental impact while maintaining printing quality |

| Fast Drying Process | Inks dry instantly upon exposure to UV light | Reduces production time and increases efficiency |

| User-Friendly Interface | Intuitive controls and touchscreen operation | Simplifies workflow and is accessible for operators of all skill levels |

| Compact Design | Space-saving footprint suitable for small shops | Maximizes productivity without needing extensive space |

The 2513 UV printer stands out in the printing industry for several reasons. Unlike traditional printing methods, it uses UV light to cure inks instantly. This process allows for printing on various surfaces, including acrylic, wood, and metal. Traditional methods, such as screen printing, typically require more setup time and can produce lengthy production runs, which might not be efficient for smaller projects. In fact, studies show that UV printing can reduce production time by up to 70%.

When it comes to print quality, UV printers offer vibrant colors and sharp details. Reports indicate that UV-printed products have improved durability and resistance to fading. This gives them an edge over conventional methods. However, it's worth noting that the initial investment for UV technology can be higher. This raises questions about its long-term cost-effectiveness for smaller businesses.

Tip: When considering printing options, assess the common projects you undertake. If versatility and speed are essential, the 2513 UV printer shines.

Additionally, while UV printing minimizes waste due to its precise application, production errors can still occur. Workers should be trained thoroughly to mitigate these issues.

Tip: Regular maintenance of the printer ensures longevity and consistent quality. Make sure to follow guidelines closely.

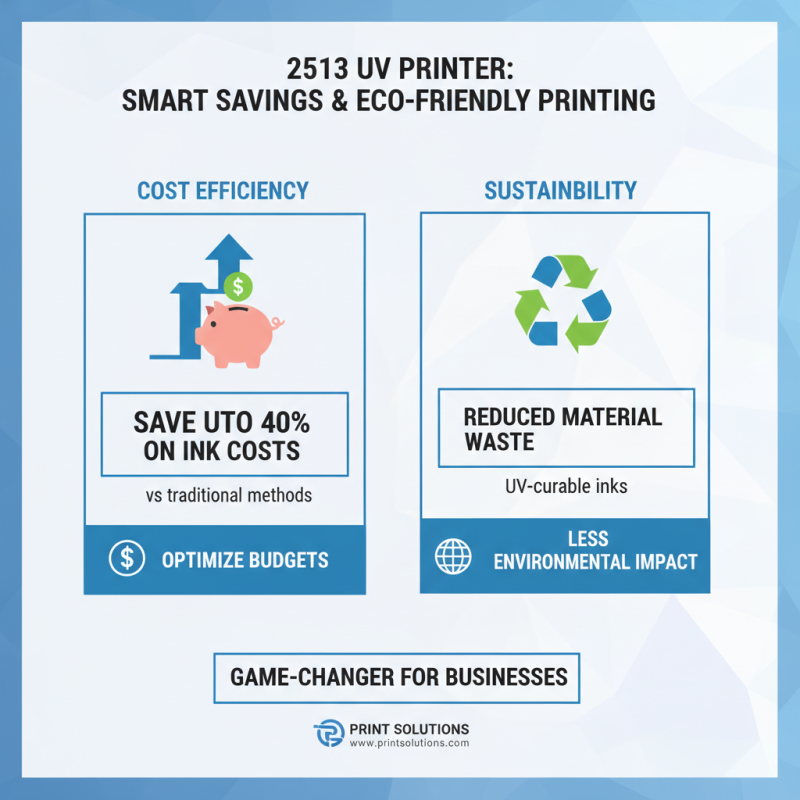

The 2513 UV printer stands out for its cost efficiency and sustainability. It utilizes UV-curable inks, which reduces wasted materials. According to recent industry research, businesses can save up to 40% on ink costs with UV technologies compared to traditional printing methods. This is a game-changer for companies looking to optimize budgets.

Sustainability is an essential factor in today's printing landscape. The printer generates minimal VOC emissions, aligning with environmental regulations. A report from the Environmental Protection Agency indicates that UV printing can reduce hazardous waste by up to 30%. This means fewer harmful substances released into the environment. Yet, despite these benefits, some users still face challenges in ink adhesion and curing. Addressing these issues is crucial for maximizing efficiency.

Further, the longevity of images printed with the 2513 UV printer is remarkable. Studies show that UV prints can last significantly longer when exposed to sunlight. However, not all substrates respond equally to UV curing. Understanding the right materials is vital for achieving the best results. Continuous experimentation and adaptation are key in leveraging this technology effectively.

The 2513 UV printer has gained traction in various industries. Its versatility is impressive. Many businesses harness its capabilities for unique applications, including signage and promotional materials. With vivid colors and durable prints, the results often exceed expectations. In fact, a recent report noted that UV printing can increase productivity by up to 30%. This efficiency is invaluable in today’s fast-paced market.

In real-world scenarios, companies report significant improvements. For instance, a small signage company utilized the 2513 UV printer to expand their product line. They went from vinyl prints to custom wood and metal signs. The results? Increased customer satisfaction and a notable boost in sales. Another business leveraged this technology for printing on promotional items, enhancing brand visibility effortlessly. They experienced a 25% revenue increase.

However, challenges remain. Not all materials are compatible with UV printing. Colors may not always be as vibrant on different substrates. Also, the initial investment can be daunting for small businesses. Effectively addressing these hurdles is essential for long-term success.