In today's competitive market, businesses must adopt innovative solutions to stand out. A Rotary UV Printer offers unique advantages for various industries. According to a recent report by Smithers Pira, the global digital printing market is expected to reach $280 billion by 2024. This growth underscores the importance of modern printing technology.

Rotary UV Printers utilize advanced UV curing technology, ensuring high-quality prints with vibrant colors. They are versatile, handling materials ranging from plastics to textiles. With a speed of up to 100 meters per minute, they enhance productivity. However, the initial investment can be daunting for small businesses.

Many companies are still hesitant due to potential maintenance issues. There’s a learning curve involved in optimizing these printers. Yet, the long-term cost benefits often outweigh initial struggles. As the market evolves, embracing Rotary UV Printers could be a pivotal move for businesses willing to adapt.

Rotary UV printers have gained traction in various industries due to their unique advantages. They deliver high-quality printing on cylindrical and uneven surfaces. This capability meets the demands of businesses in product packaging, promotional items, and custom merchandise. According to a recent industry report, businesses using rotary UV technology can see a 30% increase in production efficiency. This means faster turnaround times on custom orders, a critical factor in today’s competitive market.

One standout feature is the instant curing process. The UV light dries the ink as it prints, eliminating the long wait times associated with traditional printing methods. A survey indicated that 64% of businesses prefer this time efficiency, allowing them to increase their output. However, challenges remain. Operators must ensure consistent ink adhesion for all materials. This requires proper training and ongoing maintenance. Minor mistakes can lead to wasted prints, which can be costly and frustrating.

In terms of versatility, rotary UV printers can handle various substrates. They are effective on plastics, glass, and even textiles. This adaptability attracts diverse business sectors. Yet, some users report issues with print consistency across different materials. Addressing this requires testing and adjustments. Businesses must be prepared to adapt if they choose this technology, as it demands careful monitoring to maintain quality standards.

When considering a rotary UV printer, several key features stand out. First, the print speed must match your production goals. Industry reports indicate that printers achieving speeds of up to 100 square meters per hour can significantly enhance workflow efficiency. This is crucial in competitive markets where quick turnarounds can lead to higher sales.

Another essential feature is the printing resolution. A resolution of 1200x1200 dpi is becoming the standard for high-quality prints. This resolution ensures crisp images and fine details, which can elevate product value. However, achieving such quality often requires fine-tuning printer settings, leading to a learning curve for operators.

Additionally, the versatility of substrates can determine the printer's utility. Many rotary UV printers can print on various materials, including wood, glass, and plastic. Nevertheless, not all printers handle every substrate well. Some materials may need pre-treatment or specialized inks, making it vital to assess your specific requirements. Balancing these capabilities with operational limitations is essential for long-term success.

Rotary UV printers and traditional printers present distinct advantages and challenges. Rotary UV printers offer superior versatility. They can print on various substrates, such as wood, plastic, and metal. According to industry reports, these printers can handle complex designs with high-resolution results. Their ability to print directly on products saves time, which can boost productivity by up to 30%.

In contrast, traditional printers often rely on specific paper types. Their limitations can hinder creativity, especially when dealing with unconventional materials. The cost of traditional ink can also add up. A survey indicated that businesses that switch to UV printing see a reduction in ink costs by nearly 20%. However, not all rotary printers are perfect. Some users report challenges with maintenance and initial investment costs. Those factors can create hesitation for new buyers.

Small to medium-sized businesses could benefit greatly from adopting rotary UV printers. The speed and efficiency can transform operations. Still, careful reflection is necessary. Assessing whether the transition aligns with business goals is crucial. Understanding both the benefits and drawbacks will help make an informed decision. Balancing creativity and practicality remains essential in this industry.

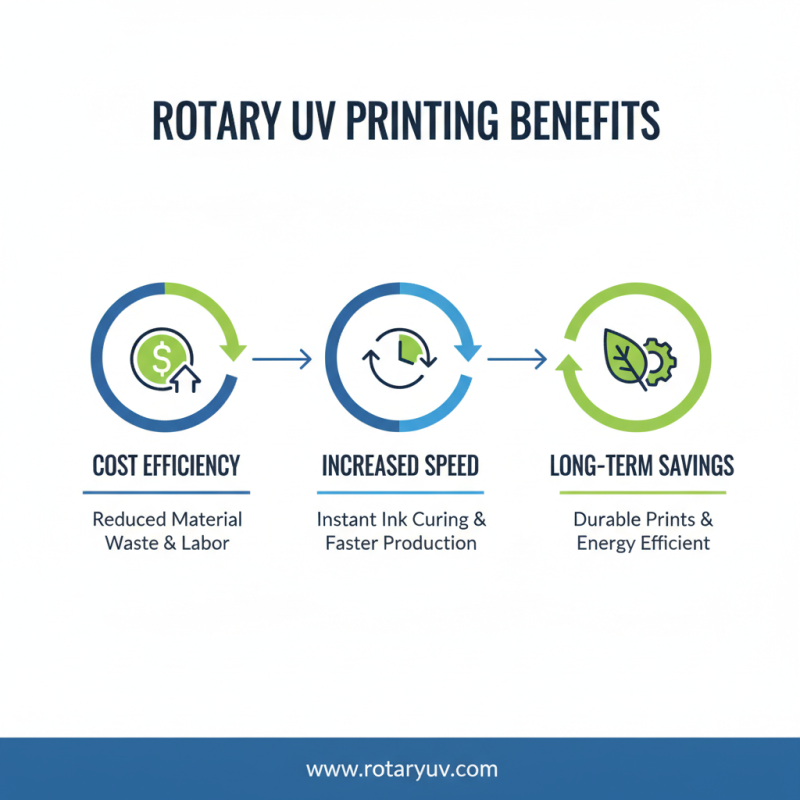

Rotary UV printing stands out for its cost efficiency and long-term benefits. This technology uses ultraviolet light to cure inks instantly. Unlike traditional methods, it minimizes waste and maximizes speed. Businesses can save on materials and labor with faster production times.

Tips: Invest in quality maintenance to extend the printer's life. Regular checks can prevent costly repairs later.

Another notable advantage of rotary UV printers is their versatility. They can handle various substrates, from wood to metal. This flexibility allows businesses to diversify product offerings. However, it’s crucial to test materials beforehand. Not all substrates respond the same way to UV printing.

Understanding your audience can aid in selecting the right materials. Analyze market trends. This insight helps in making informed choices that lead to growth. Remember that balancing creativity and practicality is key. Reflect on what works best for your business.

In recent years, many businesses have successfully integrated rotary UV printers into their operations. These printers offer flexibility and efficiency, especially for small to mid-sized companies. A custom signage company noticed a significant reduction in production time. They could create vibrant banners and displays at lightning speed. This boosted their ability to take on more projects.

Another success story comes from a promotional products firm. They faced challenges with color accuracy and material compatibility. After transitioning to rotary UV printing, their issues diminished. The printer allowed them to work on various surfaces, including wood and metal. Clients noticed a remarkable difference in the final products. However, they still need to manage wastage during the setup process.

Some companies report a learning curve when using these printers. They wrestle with understanding the software. Training employees can take time and resources. Yet, the long-term benefits often outweigh these initial hurdles. The potential for creativity and detail in printed designs is substantial. Businesses that embrace rotary UV printers are discovering new horizons.