Choosing the right UV Cylinder Printer can be challenging. With various options available, it’s crucial to understand your unique needs. A UV Cylinder Printer offers versatility and quality for numerous applications.

Think about what you will print. Whether it's bottles, cans, or cylindrical objects, size matters. Consider the maximum print area your projects will require. Technology matters too; not all printers deliver the same results. Some may produce vivid colors, while others fall short on detail.

Reflecting on your workspace is important. Ensure you have adequate space for the printer and materials. Maintenance is another factor that cannot be overlooked. A reliable UV Cylinder Printer should offer easy upkeep. Balancing cost and quality is often tricky. Investing in a high-quality model may save you money in the long run, but it requires careful consideration.

When selecting a UV cylinder printer, consider several key factors. First, print quality is essential. Look for printers that offer high-resolution options. For instance, many industry professionals recommend printers that can achieve resolutions of 1200 dpi or more. The clarity of the output can significantly impact your finished product.

Next, evaluate the speed of the printer. Efficient production is crucial for meeting deadlines. Studies show that printers capable of at least 30 square meters per hour can greatly enhance workflow. However, higher speed might compromise quality. It’s vital to find a balance.

Another important aspect is the compatibility with various substrates. Not all UV printers can handle every material. Your printer should accommodate items like glass, metal, and plastics. Data from recent market research indicates that versatility in substrates often leads to broader applications and increased sales. Reflecting on previous experiences can shape your decision. A printer that excels in one area may be lacking in another. Always weigh the pros and cons.

When considering a UV cylinder printer, understanding print resolution is crucial. Print resolution refers to the detail an image holds. It is measured in dots per inch (DPI). For example, a printer with 1200 DPI can produce finer details compared to one with 720 DPI. Higher resolution equals sharper images. However, it can also lead to longer print times and higher costs.

According to industry reports, 1440 DPI is often the sweet spot for commercial applications. This resolution balances detail and efficiency. However, not every project requires such high resolution. Choosing the right print resolution depends on the material and intended use. For large, distanced viewing, a lower DPI might suffice. On the other hand, fine art prints demand higher resolutions.

A common misconception is that higher DPI always means better quality. Yet, if the source file lacks detail, increasing DPI won't enhance the outcome. It can lead to larger file sizes and wasted resources. Therefore, it’s vital to align your project needs with appropriate print settings. Balancing resolution, production speed, and costs can be a complex decision. Make sure to evaluate your specific requirements before finalizing your choice.

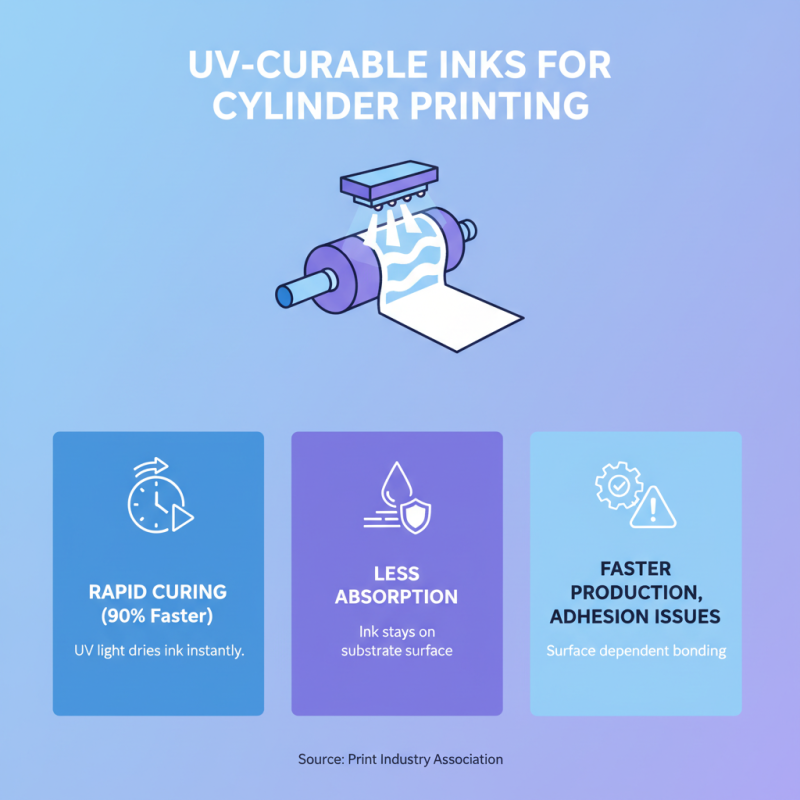

When considering UV-curable inks for cylinder printing, it's essential to understand their unique properties. UV inks dry quickly when exposed to UV light. This rapid curing leads to less ink being absorbed by the substrate. According to the Print Industry Association, UV inks can reduce dry times by up to 90%. This attribute allows for faster production cycles, but may sometimes lead to issues with adhesion on certain surfaces.

Tips: Test the ink on various substrates. Not all materials bond well with UV inks. Conduct adhesion tests before full-scale production.

Another advantage of UV-curable inks is their durability. They resist scratches and chemicals better than traditional inks. A report by the Ink Manufacturers Association notes that UV inks often exceed 50% greater abrasion resistance compared to solvent-based inks. However, be cautious; while durability is a strong point, not all UV inks perform well in outdoor conditions.

Tips: Research the specific UV ink formulations for outdoor use. Longevity can vary based on pigment types and curing setups.

It's crucial to also consider the environmental impact. UV inks typically emit fewer volatile organic compounds (VOCs). This is beneficial for meeting regulatory standards. Yet, some manufacturers still use harmful additives in their formulations. Always check the safety data sheets. Production methods and materials need consistent evaluation to ensure optimal results.

When choosing a UV cylinder printer, production speed is a crucial factor. A faster printer can significantly enhance workflow efficiency. It helps meet tight deadlines and increases output. Imagine a busy print shop where every minute counts. Clients expect quick turnarounds. If the printer lags, opportunities might be lost.

However, not all speed comes without cost. High-speed machines may produce inconsistencies. Think about color accuracy. Rushing through print runs can lead to errors. Carefully assess the trade-off between speed and quality. A balanced approach is key. Even a slight dip in quality can lead to reprints, which ultimately slows down production.

Consider how your team operates. If your workflow relies on fast turnarounds, invest in a high-speed printer. But ensure it meets quality standards. Testing the printer before making a decision can reveal potential shortcomings. Efficiency shouldn’t come at the expense of your reputation. With the right choice, your operation can thrive with speed and precision.

When thinking about a UV cylinder printer, consider both costs. The initial investment can be daunting. You may need to save or budget carefully. However, break down these costs. What do you get for your money? A printer may seem expensive initially, but its features can offer long-term gains.

Evaluate how much printing work you’ll handle. A higher upfront cost might lead to better efficiency and less downtime. Maintenance can also affect overall costs. Sometimes, cheaper models demand more repairs. This is crucial to keep in mind. Reflect on how often you will use the printer. Consistent usage can justify a larger investment.

Think about the quality of prints as well. If your projects require high resolution, settling for less might hurt your reputation. It’s essential to strike a balance. Sometimes spending more can yield better results. Don’t forget about energy consumption, either. Some models can be more efficient over time. Weigh these factors carefully when making your decision.

| Feature | Initial Investment (USD) | Operating Costs (Yearly) | Maintenance Costs (Yearly) | Average Lifespan (Years) | Estimated ROI (%) |

|---|---|---|---|---|---|

| Basic Model | $10,000 | $2,000 | $500 | 5 | 150% |

| Mid-Range Model | $20,000 | $1,500 | $700 | 7 | 200% |

| High-End Model | $35,000 | $1,000 | $1,000 | 10 | 250% |

| Eco-Friendly Model | $25,000 | $1,800 | $600 | 8 | 180% |