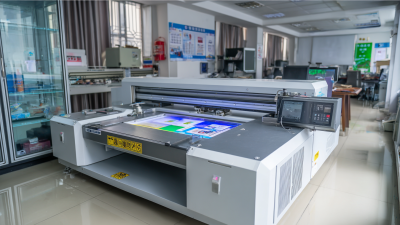

In today’s printing world, technology evolves rapidly. The 2513 UV printer stands out among various options. It offers unique advantages that can meet diverse printing needs. This printer utilizes UV curing technology. It delivers high-quality prints with vivid colors. Many users seek durability and efficiency.

Choosing a 2513 UV printer can be a game-changer. It supports a variety of materials. You can print on wood, glass, metal, and more. Each print is durable and resistant to fading. Users often appreciate the quick drying time. This feature minimizes delays in production. However, understanding its capabilities is crucial.

Some might wonder about the initial investment. It can be higher compared to traditional printers. Nevertheless, the long-term benefits often outweigh costs. Consider the potential for increased production and higher quality. Customers continuously seek innovative solutions. The 2513 UV printer could be the answer they need. It invites reflection on what you value in printing technology.

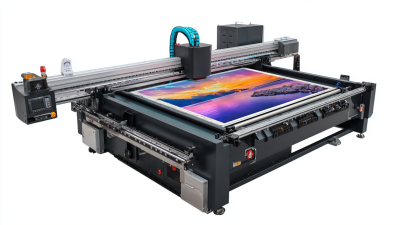

A 2513 UV printer is a powerful tool for various printing needs. Its ability to print on diverse materials is one of its key advantages. You can print on wood, glass, metal, and even fabric. This versatility opens up endless creative possibilities. For example, imagine printing vibrant designs on wooden signs or detailed graphics on glass surfaces.

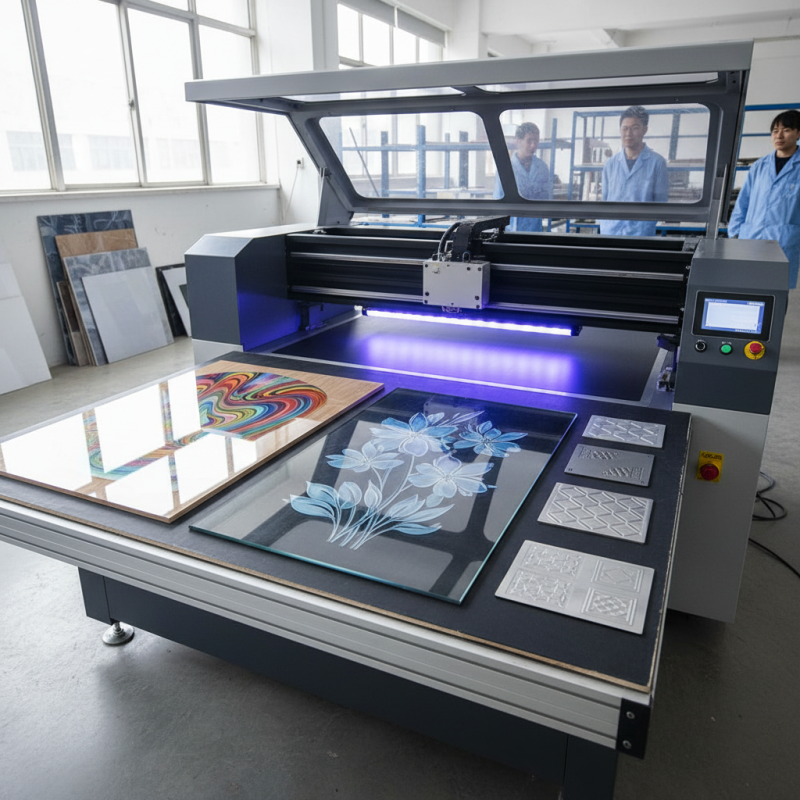

Additionally, UV printing provides immediate results. The ink cures quickly under UV light, minimizing waiting time. This feature is particularly useful for high-volume jobs or tight deadlines. You can produce intricate designs without worrying about smudging or fading. Yet, it’s crucial to ensure that materials are compatible with UV inks. Some substrates may need special treatment.

Durability is another benefit. UV prints are resistant to scratches and water. This makes them suitable for both indoor and outdoor use. However, the longevity can vary based on the material used. There may be challenges in achieving uniformity across different surfaces. Experimentation might be required to find the best approach. Embracing these imperfections can lead to unique and eye-catching results.

The 2513 UV printer is known for its impressive printing quality. Its ability to print on various materials is a significant advantage. This versatility opens up many possibilities for creative projects. Businesses can use it for signage, promotional materials, and interior design.

One of the key features is its advanced curing technology. This technology ensures that ink dries instantly, preventing smudges. The printer delivers vibrant colors and sharp details. This helps attract attention and stands out in competitive markets. The built-in precision mechanism enhances accuracy, ensuring that even intricate designs are printed flawlessly.

However, there are considerations to reflect on. While the printer offers quick production, setup can be complex. Some users may find the initial learning curve steep. Others reported that maintaining optimal performance requires regular cleaning and calibration. This can be time-consuming, but the results often justify the effort.

When considering printing needs, a 2513 UV printer presents distinct advantages over conventional options. One major benefit is its ability to print on various materials. Wood, glass, plastic, and metal are all suitable substrates. This flexibility opens avenues for creative projects that traditional printers can't handle.

Color vibrancy is another strong point. 2513 UV printers utilize specially formulated inks that maintain their brilliance over time. This results in durable prints that resist fading. However, achieving optimal color accuracy can sometimes be challenging. Users must consider proper calibration, which might require extra time.

Another factor to weigh is efficiency. UV printers typically offer faster drying times. Prints come out dry and ready for immediate handling. Yet, the upfront cost of these printers can be daunting. For some, the investment may require careful financial consideration. It’s important to evaluate overall operational costs before making a decision.

| Feature | 2513 UV Printer | Conventional Printer |

|---|---|---|

| Print Quality | High resolution with vibrant colors | Moderate resolution, colors may vary |

| Substrate Variety | Can print on various materials (wood, metal, glass, etc.) | Limited to specific paper types |

| Drying Time | Instant curing using UV light | Requires drying time for inks |

| Durability | Highly durable, resistant to scratches and water | Less durable, prone to fading and water damage |

| Environmental Impact | Uses eco-friendly UV inks | Inks may contain harmful solvents |

| Initial Cost | Higher initial investment | Lower initial cost |

| Long-Term Savings | Lower maintenance and material costs | Higher material costs over time |

When considering printing solutions, the 2513 UV printer stands out. The cost-effectiveness of this printer is one key reason. It utilizes UV technology, which cures ink quickly. This leads to faster production times and less waste. Efficient use of materials is favored, making every print more valuable.

Tip: Always calculate production costs ahead of time. Understand the materials you'll use. Compare these costs with other printing technologies. You might be surprised.

Another advantage is the versatility of the 2513 UV printer. It can print on various surfaces. Wood, metal, and acrylic are just a few examples. This flexibility can cater to different client needs, reducing the necessity for multiple printers. However, consider the learning curve associated with such advanced technology.

Tip: Take time to train your staff properly. It's essential for maximizing efficiency. Otherwise, the complexity may lead to inefficiencies. Investing time in the setup can pay off significantly.

When it comes to versatile printing solutions, the 2513 UV printer stands out. This technology has broad applications across various industries. Sign makers appreciate its ability to print on materials like acrylic and metal. It allows for stunning graphics that attract customers.

Furniture makers also benefit from 2513 UV printing. They can create lasting patterns directly on surfaces. It reduces the need for additional finishes. However, achieving the perfect print can require careful calibration. Inconsistent settings may lead to faded colors or messy edges.

Tips: Always prepare the surface properly before printing. A clean surface ensures better adhesion. This simple step can improve the quality drastically.

Moreover, packaging industries find value in this technology. Unique textures and vibrant colors make products more appealing. But, it’s crucial to test inks and materials first. Not all combinations yield optimal results. Variability can affect output significantly, so experimentation is key.