The rapid evolution of printing technology has led businesses to adopt innovative solutions that enhance productivity and quality. The 6090 UV Flatbed Printer stands out as a crucial tool tailored for various industries, allowing for versatile printing on a wide range of materials. According to a report by Smithers Pira, the global flatbed printer market is projected to reach $3.8 billion by 2026, driven by the increasing demand for high-quality printing in signage, packaging, and custom products. This trend underscores the need for businesses to integrate advanced printing technologies like the 6090 UV Flatbed Printer to remain competitive and meet customer expectations.

Expert in the field, Dr. Jane Thompson, highlights the advantages of the 6090 UV Flatbed Printer, stating, “The ability to print directly on various substrates with superior quality and durability makes the 6090 an invaluable asset for any business looking to innovate.” Her insights reflect a growing recognition of the necessity for printers that combine efficiency with quality, further emphasized by a study from Keypoint Intelligence which found that businesses utilizing UV printing technologies reported a 25% increase in production speeds.

As the demand for high-quality prints continues to rise, the 6090 UV Flatbed Printer offers a solution that not only meets but exceeds the expectations of professionals across multiple sectors. Embracing this technology is essential for businesses aiming to enhance their operational capabilities and deliver top-notch products to their clients.

The 6090 UV flatbed printer has gained significant traction across various industries due to its versatility and impressive print quality. In sectors such as signage, packaging, and interior decoration, the demand for high-resolution and durable print outputs has increased exponentially. According to a report from Smithers Pira, the global digital printing market is expected to grow at a CAGR of 12% through 2025, reflecting a shift towards innovative printing technologies like the 6090 UV flatbed printer that can cater to this demand.

One of the standout benefits of the 6090 UV flatbed printer lies in its ability to print on a wide variety of substrates, ranging from rigid materials like wood and glass to flexible ones such as vinyl. This adaptability allows businesses in industries such as furniture design and promotional goods to create unique, customized products that meet specific client needs. A study by Technavio indicates that the growing trend of personalization in both consumer and commercial products is a key driver for adopting UV printing technology, reinforcing the 6090 printer's role in enhancing competitive advantage.

Furthermore, the 6090 UV flatbed printer's quick curing time enables rapid production cycles, leading to increased productivity. An industry analysis by Grand View Research highlighted that the demand for quick turnaround times in print services is on the rise, particularly in fast-paced markets like e-commerce and event management. This efficiency not only reduces lead times but also allows businesses to take on more projects simultaneously, ultimately resulting in higher profit margins and enhanced customer satisfaction.

| Industry | Benefits | Applications | Print Quality | Cost Efficiency |

|---|---|---|---|---|

| Advertising | High-quality prints with vivid colors | Banners, signage, promotional displays | Up to 1440 dpi | Lower material waste, quick turnarounds |

| Packaging | Versatile printing on various materials | Boxes, labels, custom packaging designs | High precision | Reduced setup and material costs |

| Arts and Crafts | Ability to print on thin substrates | Custom artwork, photo prints, decor items | Stunning detail | Efficient for limited runs and prototypes |

| Manufacturing | Durable prints ideal for industrial applications | Panel printing, labels, machine parts | Resistant to fading and wear | Streamlined production process |

| Signage | Quick production for custom signs | Indoor and outdoor signage | Bright, vibrant colors | Enhanced operational efficiency |

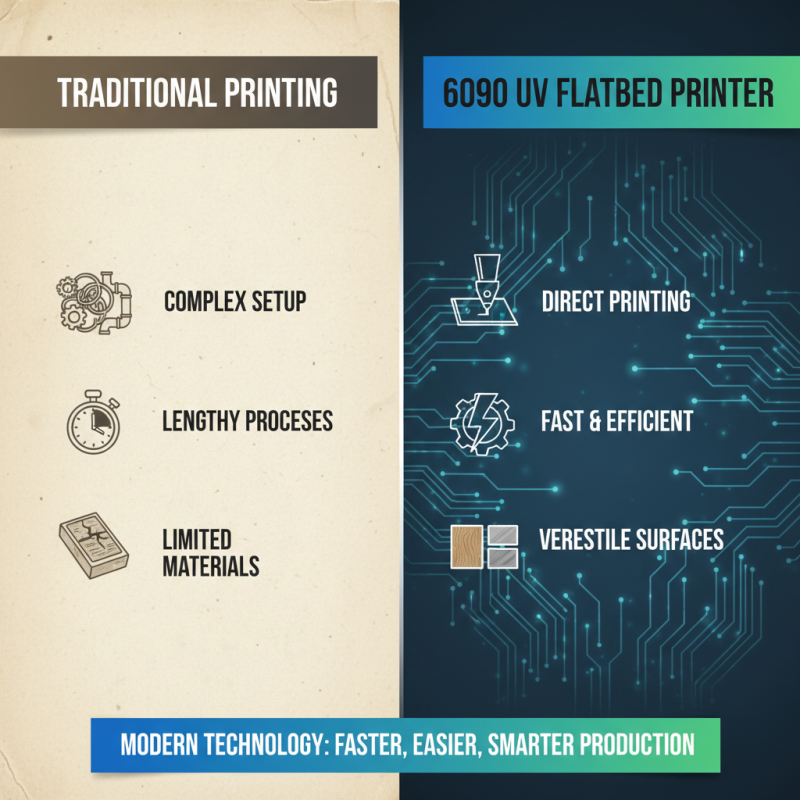

When comparing the 6090 UV flatbed printer with traditional printing methods, it's essential to recognize several advantages that modern technology brings to the table. Traditional printing often involves complex setups and lengthy processes, which can delay project timelines. In contrast, the 6090 UV printer enables direct printing on various surfaces including wood, glass, and metal. This capability significantly reduces the need for multiple processes, making production faster and more efficient.

Tip: To maximize the benefits of a 6090 UV printer, consider investing in high-quality substrates. The quality of the surface can greatly influence the final print, ensuring vibrant colors and durability.

Another vital difference lies in customization and flexibility. Traditional printing methods may require predetermined adjustments for different materials, while the 6090 UV printer allows for quick changes between jobs. This versatility is particularly beneficial for businesses that require bespoke designs or low-volume runs. It enhances the ability to cater to specific customer requests without incurring significant costs.

Tip: Regular maintenance of the printer heads is key to sustaining print quality and prolonging the lifespan of your 6090 UV printer. Implement a routine cleaning schedule to avoid any build-up that could affect performance.

The 6090 UV flatbed printer stands out in the printing industry due to its versatile capabilities and advanced technology. One of its key features is its ability to print on a wide variety of materials, ranging from glass and metal to wood and plastic. According to a report by Smithers Pira, the digital printing market is expected to grow significantly, with UV printing technologies poised to increase in demand as businesses seek high-quality, durable outputs. The inherent ability of UV-flatbed printers to produce vivid colors with precise details makes them ideal for applications in signage, packaging, and decorative elements.

Another significant advantage of the 6090 UV flatbed printer is its efficiency. This technology allows for direct printing onto substrates, which reduces the need for additional setups or transfers, streamlining the production process. A survey conducted by Ink World highlights that UV printers can operate at speeds up to three times faster than traditional printing methods, increasing overall productivity. Additionally, the instant curing process of UV inks not only accelerates production but also enhances durability, resulting in prints that are resistant to scratches, fading, and weather conditions. This combination of efficiency and quality positions the 6090 UV flatbed printer as an essential asset for businesses looking to meet diverse customer needs while maximizing operational output.

The 6090 UV flatbed printer is revolutionizing the way businesses approach their printing needs, particularly in terms of cost efficiency. One of the standout advantages of utilizing this printer is its capability to produce high-quality prints on a variety of materials without incurring significant additional costs. Traditional printing methods often require numerous setup and maintenance expenses, but the 6090 UV printer simplifies this process, allowing for quick adjustments and reduced waste. This efficiency not only speeds up production but also lowers the overall operational costs.

Moreover, the UV curing technology employed by the 6090 printer enables instant drying of prints, minimizing the turnaround time and maximizing productivity. Unlike conventional inks that may smudge or need extended drying periods, UV inks adhere quickly, which means businesses can handle multiple jobs within the same time frame. This rapid output is particularly beneficial for companies with high-volume demands, as it translates to increased profitability without sacrificing quality. By integrating a 6090 UV printer into their workflow, businesses can achieve both cost savings and enhanced output capacity, ultimately contributing to a healthier bottom line.

The 6090 UV flatbed printer stands out as a transformative tool for businesses looking to enhance their customization capabilities. In a market where personalization is increasingly critical, the versatility of UV printing allows companies to meet diverse customer demands effectively. According to a recent industry report by Grand View Research, the global UV printing market is expected to reach USD 8.5 billion by 2025, reflecting a robust annual growth rate driven by the need for high-quality, customized products across various sectors.

One of the primary advantages of the 6090 UV flatbed printer is its ability to print on a wide range of materials, including wood, glass, acrylic, and metal. This flexibility enables businesses to expand their offerings, catering to industries from signage and packaging to promotional items and home decor. A study published by Smithers Pira highlights that digital printing technologies, including UV printing, are now the preferred choice for 40% of businesses seeking to offer unique products, underscoring the value of this technology in enhancing customer engagement and satisfaction.

Furthermore, the exceptional print quality and durability that UV flatbed printers provide can significantly improve a company’s competitive edge. With the ability to produce vibrant colors and intricate designs that withstand the test of time, businesses can delight their customers while reducing the frequency of reprints. As companies increasingly recognize the importance of innovation and customization, investing in a 6090 UV flatbed printer can strategically position them for growth in today’s dynamic marketplace.