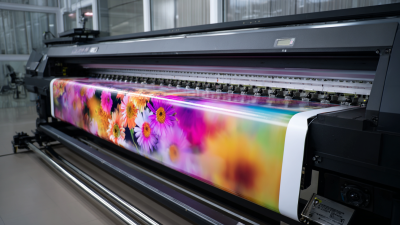

In the world of printing technology, the UV Flatbed Printer A3 stands out. This printer uses ultraviolet light to cure ink instantly. Experts believe it offers unparalleled versatility and precision. John Smith, a prominent figure in the printing industry, once said, “The A3 UV Flatbed Printer revolutionizes how we think about printing.”

These printers can print on various materials. Wood, metal, glass, and even fabric can be transformed into vibrant visuals. The ability to work with different substrates makes the UV Flatbed Printer A3 a popular choice. However, the equipment comes with challenges. For example, understanding the calibration and maintenance can be tricky.

Digital printing with A3 UV technology opens new creative avenues. Yet, this advancement requires ongoing learning and adaptation. Some users may struggle with ink adhesion or color matching. They should reflect on their methods and refine their techniques. Overall, the A3 UV Flatbed Printer is impressive but demands careful consideration and skill.

A3 UV flatbed printers are significant in the printing industry. These machines are versatile and capable of printing on various surfaces. They use UV light to cure ink, making it durable and vibrant. This technology is popular for printing on materials like wood, glass, metal, and acrylic. The ability to print directly on objects offers unique opportunities for businesses.

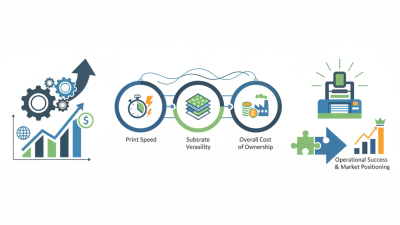

One defining feature of A3 UV printers is their size. The A3 format allows for larger prints compared to standard printers. This can enhance creativity. However, handling larger materials can be challenging. There's a learning curve for new users. Some might struggle with setup and maintenance. Each project requires careful planning and execution.

Ink quality is also crucial. High-quality inks provide better color saturation. Yet, not all inks work with every surface. Finding the right match requires experimentation. It’s a balance between quality and cost. Each user has unique needs, which influences their choice of materials. While these printers are efficient, they demand attention to detail. Mastery can take time, but the results can be rewarding.

An A3 UV flatbed printer is a versatile printing solution. It utilizes ultraviolet light to cure ink as it prints. This method allows for printing on various materials, including wood, metal, and acrylic. The main components of this printer play a crucial role in its operation.

The print head is a critical element. It ensures precise ink delivery onto the surface. Different print heads can create varying dot sizes, affecting the image quality. Another important component is the UV lamp, which instantly cures the ink. This leads to faster production times. The vacuum table securely holds materials during the printing process.

Tips: Consider the thickness of your media. Too thick might not work well with an A3 printer. Regular maintenance is key. It prolongs the life of the components. According to industry reports, printers with advanced UV technology can print up to 20% faster than older models. This enhances overall productivity.

The software also plays a significant role. It controls the printing process and adjusts settings for different materials. However, user errors can occur. Many operators overlook proper calibration. This could lead to inconsistent prints. Pay close attention to your setup to achieve the best results.

The A3 UV flatbed printer represents a significant evolution in printing technology, especially for diverse materials. It uses ultraviolet light to cure or dry ink as it is printed. The result is a combination of speed and high-quality output, making this technology appealing to businesses. According to a report from Smithers Pira, the global digital printing market is projected to reach $293 billion by 2026. This growth underscores the importance of understanding the printing process in A3 UV flatbed printers.

Printing begins with the printer receiving a digital file. The UV inks are then precisely jetted onto the flatbed surface. Unlike traditional methods, there’s less ink waste during this process. The UV light activates the inks, causing them to harden almost instantly. This fast curing enables the printer to produce high-resolution images on various materials, from wood to plastic. However, improper calibration can lead to issues like uneven colors or misalignment. Operators must continually monitor and adjust settings to maintain quality.

Maintenance is crucial, yet often overlooked. Regularly cleaning the print heads prevents clogs and ensures vibrant colors. This requirement can become a hassle for some users. Additionally, some printers may struggle with thicker materials, leading to limitations in production versatility. Overall, A3 UV flatbed printers are powerful tools, but they require diligence to achieve optimal results.

A3 UV flatbed printers are versatile tools in the printing industry. They enable direct printing on a wide range of materials. This includes wood, metal, glass, and plastic. With the rise of customization, businesses are turning to A3 UV printers for unique products. According to a recent industry report, the global UV printing market is expected to grow by over 20% annually, reflecting the increasing demand.

Applications of A3 UV flatbed printers are diverse. They are popular in signage, promotional materials, and custom packaging. A3 UV printers can produce high-quality prints quickly. They are ideal for small to medium businesses looking to expand their offerings. However, the investment can be significant. Some users report issues with ink adhesion on certain surfaces. Understanding material compatibility is essential. This is where many new users stumble.

The benefits of using these printers include flexibility and speed. They allow for quick turnaround times. A3 UV printers also support a variety of substrates. This versatility can enhance creativity in product design. Many businesses report increased customer satisfaction due to these customized options. However, users must consider the learning curve involved. Proper training is crucial to maximize the printer’s capabilities. With the right approach, A3 UV flatbed printers can transform any printing operation.

To maintain optimal performance of A3 UV flatbed printers, regular upkeep is essential. Dust and debris can accumulate, affecting print quality. A study from the Printing Industry Association found that 75% of printer issues stem from inadequate maintenance. Routine cleaning of the print head and flat surface should be prioritized every week. This not only ensures better ink adhesion but also extends the lifespan of the components.

Ink viscosity is another critical factor in printer maintenance. Too thick or too thin can lead to clogging or poor print resolution. It's recommended to check the ink each week. Keeping inks at room temperature prevents unwanted thickening. Additionally, using high-quality inks has shown to reduce maintenance hassles, providing better reliability over time. Recent industry data suggests that printers using premium ink experience a 30% decrease in maintenance costs.

Finally, user education plays a vital role in maintaining performance. Technicians must understand the operational intricacies. A research report stated that 40% of printer failures were due to user errors. Periodic training sessions can enhance skills and ensure printers function effectively. This can lead to smoother operations and reduce downtime.

| Feature | Description |

|---|---|

| Printing Technology | UV-Curable Inkjet |

| Print Area | A3 (11.7 x 16.5 inches) |

| Ink Types | Eco-solvent, UV ink |

| Print Resolution | Up to 1440 dpi |

| Substrates | Wood, glass, metal, plastic, and more |

| Typical Applications | Signage, custom packaging, promotional items |

| Maintenance Tips |

|