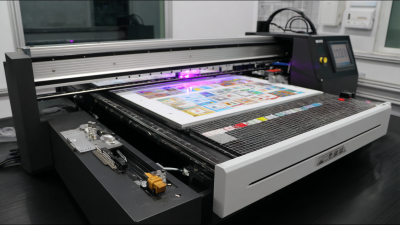

In an era where customization is paramount, the 6090 UV Flatbed Printer stands out as a transformative tool for designers and businesses alike. According to a recent report by Smithers Pira, the digital printing market is projected to reach $350 billion by 2025, driven largely by demand for personalized and bespoke solutions. As industries pivot towards unique branding and tailored experiences, the capabilities of the 6090 UV Flatbed Printer enable a new level of innovation in custom design projects. This advanced printer not only supports a variety of substrates—from textiles to rigid materials—but also produces vibrant, long-lasting prints that meet the evolving aesthetic demands of consumers. With its efficiency and versatility, the 6090 UV Flatbed Printer is poised to revolutionize the way designers approach their projects, unlocking a realm of creative possibilities that were previously unattainable.

In an era where customization is paramount, the 6090 UV Flatbed Printer stands out as a transformative tool for designers and businesses alike. According to a recent report by Smithers Pira, the digital printing market is projected to reach $350 billion by 2025, driven largely by demand for personalized and bespoke solutions. As industries pivot towards unique branding and tailored experiences, the capabilities of the 6090 UV Flatbed Printer enable a new level of innovation in custom design projects. This advanced printer not only supports a variety of substrates—from textiles to rigid materials—but also produces vibrant, long-lasting prints that meet the evolving aesthetic demands of consumers. With its efficiency and versatility, the 6090 UV Flatbed Printer is poised to revolutionize the way designers approach their projects, unlocking a realm of creative possibilities that were previously unattainable.

The impact of the 6090 UV flatbed printer on custom design efficiency is substantial, enabling designers to transform creative visions into reality with speed and precision. Given its capability to print directly onto a variety of substrates, this printer streamlines the workflow, allowing for immediate customization and quicker turnaround times. By minimizing setup time and reducing production costs, designers can focus on innovation rather than the limitations of traditional methods.

The impact of the 6090 UV flatbed printer on custom design efficiency is substantial, enabling designers to transform creative visions into reality with speed and precision. Given its capability to print directly onto a variety of substrates, this printer streamlines the workflow, allowing for immediate customization and quicker turnaround times. By minimizing setup time and reducing production costs, designers can focus on innovation rather than the limitations of traditional methods.

Tips for Maximizing Efficiency with UV Flatbed Printers:

The integration of advanced UV printing technology is transforming the landscape of custom design projects, showcasing how tools like the 6090 UV flatbed printer can enhance creative expression. This innovative machine utilizes ultraviolet light to cure ink as it’s printed, allowing for immediate drying and enabling designs on a variety of substrates. The versatility offered by this technology means artists and designers can explore new dimensions of creativity, producing vibrant and intricate patterns that were once difficult to achieve with traditional printing methods.

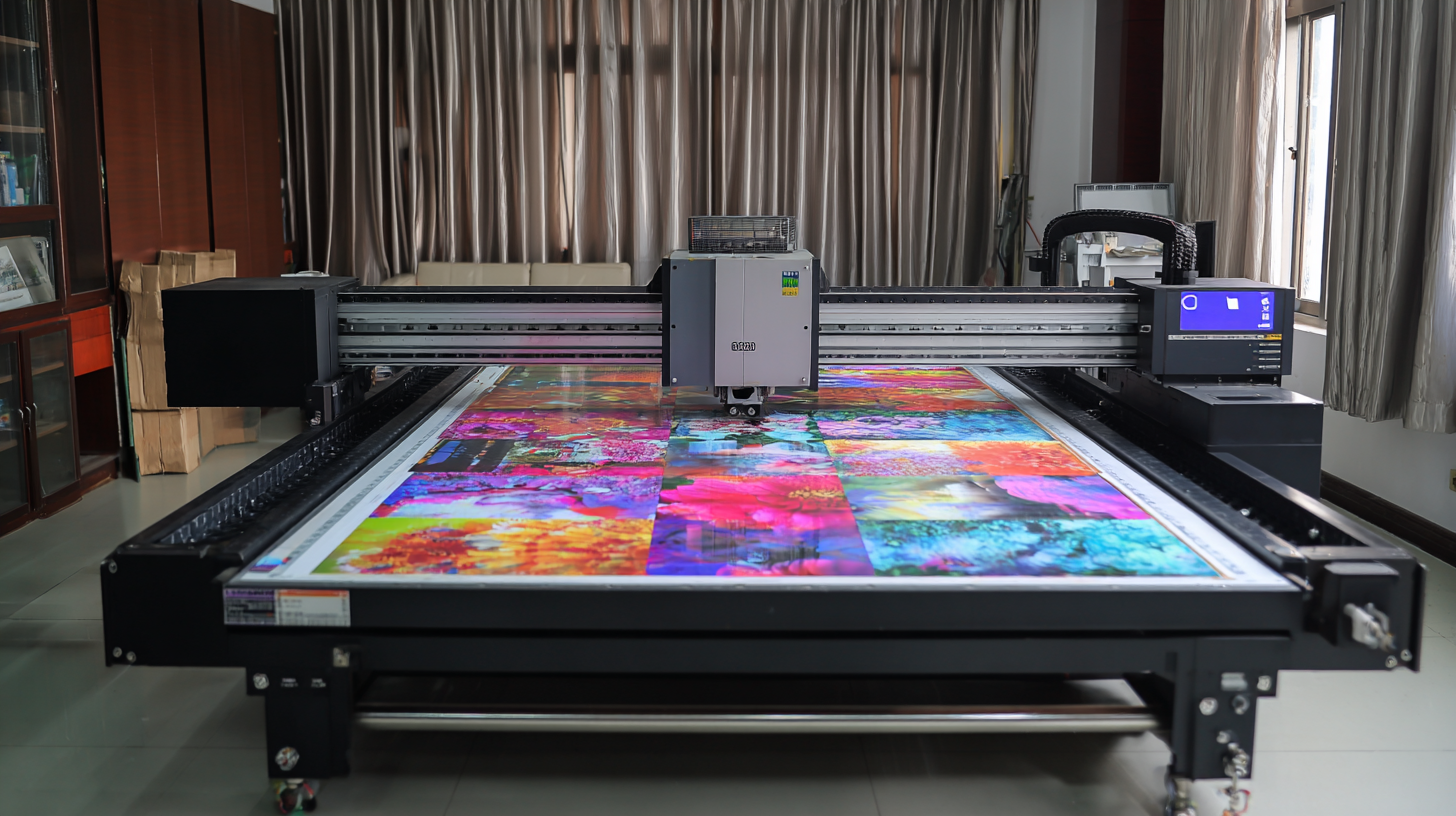

Moreover, the 6090 UV flatbed printer opens new avenues for personalization in design work. Customization is no longer limited to just paper; designers can print on materials such as wood, glass, and metal. This capability invites a wider range of artistic experimentation, encouraging creators to push boundaries and invent original pieces that reflect their unique visions. As a result, the integration of advanced UV technology not only boosts efficiency but also ignites the spark of creativity, making it an essential tool for anyone looking to revolutionize their custom design projects.

The 6090 UV Flatbed Printer has emerged as a game-changer in custom design projects, enabling creatives to explore limitless possibilities. In various case studies, designers have successfully utilized this innovative technology to enhance their work. For instance, a local signage company transformed their offerings by using the 6090 printer to produce vibrant, custom prints on materials like wood, metal, and acrylic. This flexibility allowed them to cater to specific client needs, resulting in unique designs that stand out in a competitive market.

Another case highlights an interior designer who used the flatbed printer to create bespoke wallpaper patterns. By printing directly onto the material, she was able to craft stunning, one-of-a-kind interiors that perfectly matched her clients' aesthetics. This personalized approach not only elevated her projects but also significantly increased client satisfaction.

**Tips:** When considering the 6090 UV Flatbed Printer for your design projects, think outside the box. Experiment with different substrates and textures to enhance the visual impact of your designs. Additionally, consider the printer's capabilities for special finishes, as these can add depth and intrigue to your creations, making them even more appealing to potential clients.

The introduction of the 6090 UV Flatbed Printer marks a significant advancement in custom design projects, particularly in terms of cost-effectiveness. By utilizing advanced UV printing technology, this printer offers remarkable versatility, allowing creators to print on various materials, including wood, plastic, glass, and metal. This adaptability not only broadens the scope of possible custom designs but also reduces the reliance on multiple machines, ultimately lowering operational costs. As a result, businesses can expect an impressive return on investment (ROI), as the ability to execute intricate designs efficiently opens new revenue streams.

Furthermore, the booming stickers market exemplifies the financial benefits of integrating the 6090 UV printer into design workflows. With the global stickers market projected to experience significant growth, the demand for high-quality, customizable products is on the rise. The 6090 UV printer not only meets this demand by delivering exceptional quality but also does so at a lower cost compared to traditional printing methods. This innovation not only enhances profitability for businesses but also positions them to respond dynamically to market trends, ensuring they remain competitive in an ever-evolving landscape.

The landscape of creative industries is rapidly evolving, and UV printing technology is leading the charge. According to Smithers Pira, the UV printing market is projected to grow from $5 billion in 2020 to an impressive $10 billion by 2025, highlighting its increasing significance in custom design projects. This growth is largely driven by the demand for versatile solutions that allow for unique, high-quality outputs on various substrates, including textiles, ceramics, and acrylics. The 6090 UV Flatbed Printer is at the forefront of this transformation, offering unprecedented opportunities for designers to explore complex graphics and incorporate textures that were previously challenging to achieve.

Moreover, advancements in UV printing technology are reshaping how creative professionals approach their projects. A report from Grand View Research indicates that the global digital printing market size is expected to reach $27.3 billion by 2027, with UV printing playing a pivotal role in this increase. As customers demand more personalized products, the 6090 UV Flatbed Printer empowers businesses to deliver customized solutions efficiently, enhancing creativity and reducing turnaround times. This versatility not only fosters innovation but also positions UV printing as a pivotal factor in shaping the future of creative industries, enabling designers to think outside the conventional boundaries of print.

| Dimension | Details |

|---|---|

| Print Area | 1200 mm x 900 mm |

| Print Speed | Up to 50 m²/h |

| Resolution | 1200 x 1200 dpi |

| Ink Type | UV-Curable Ink |

| Supported Materials | Wood, Glass, Metal, Acrylic |

| Applications | Signage, Packaging, Custom Art, Promotional Products |

| Future Trends | Increased customizability, Sustainability, Integration with AI |