Inquiry

Form loading...

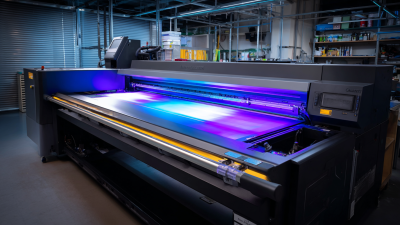

The advent of the 6090 UV Flatbed Printer marks a significant milestone in the evolution of printing technology, addressing the growing demand for versatile, high-quality printing solutions across various industries. According to a recent market analysis from Smithers Pira, the global digital printing market is projected to reach $187 billion by 2024, driven by innovations like UV flatbed printers. The 6090 UV Flatbed Printer offers unparalleled capabilities, including the ability to print on a multitude of substrates, ranging from wood to glass, which significantly boosts production efficiency. Its eco-friendly UV curing technology also ensures that there is minimal waste, aligning with the industry's increasing emphasis on sustainability. As businesses look for ways to enhance their offerings while remaining competitive, the 6090 UV Flatbed Printer is poised to revolutionize the printing landscape by delivering exceptional quality and adaptability.

The 6090 UV Flatbed Printer is a cutting-edge printing solution that offers remarkable features and specifications tailored for various printing needs. With its large printing area of 60x90 cm, it accommodates a wide range of materials, including plastics, wood, metal, and more. This versatility allows businesses to expand their service offerings, catering to diverse industries from signage to promotional items. The printer employs UV curing technology, which ensures vibrant colors and sharp details while significantly reducing drying time, making it highly efficient for both small and large production runs.

The 6090 UV Flatbed Printer is a cutting-edge printing solution that offers remarkable features and specifications tailored for various printing needs. With its large printing area of 60x90 cm, it accommodates a wide range of materials, including plastics, wood, metal, and more. This versatility allows businesses to expand their service offerings, catering to diverse industries from signage to promotional items. The printer employs UV curing technology, which ensures vibrant colors and sharp details while significantly reducing drying time, making it highly efficient for both small and large production runs.

Tips: When considering the 6090 UV Flatbed Printer, it's essential to assess your specific printing requirements. Evaluate the types of materials you plan to use, as well as the volume of prints you expect to produce. Additionally, maintaining the printer regularly can enhance its longevity and performance.

Incorporating advanced features like a retractable flatbed, adjustable height, and user-friendly software, the 6090 UV Flatbed Printer adapts easily to various production workflows. Its eco-friendly inks are not only safe for the environment but also provide excellent adhesion and durability, ensuring that your prints withstand the test of time. By investing in this innovative printing technology, businesses can stay competitive and deliver high-quality products that meet modern consumer demands.

The 6090 UV Flatbed Printer is transforming the printing landscape across various sectors. Its advanced technology allows for direct printing on a wide range of materials, including wood, metal, glass, and acrylic. According to a report by Smithers Pira, the UV printing market is expected to grow at a CAGR of 8.2% over the next five years, signifying increasing industry adoption of such versatile printers. This rapid growth highlights how businesses leverage the 6090 for both small-scale and large-scale production, enabling customized and high-quality outputs efficiently.

One of the key advantages of the 6090 UV Flatbed Printer is its capacity for printing vivid colors and intricate designs without the need for pre-treatment on substrates. This not only saves time but also minimizes production costs. In textile and signage industries, for instance, companies have reported up to a 20% reduction in material waste when utilizing UV technology. Moreover, the immediate curing process allows for swift handling and delivery, making it particularly beneficial for businesses with tight deadlines.

Tips for maximizing the potential of the 6090 UV Flatbed Printer include regularly maintaining the printer to ensure optimal performance and utilizing high-quality inks specifically designed for UV printing. Additionally, experimenting with different substrates can help businesses discover new opportunities for product offerings. As industries continue to adapt and innovate, investing in the 6090 is a strategic move toward enhancing production capabilities.

The 6090 UV flatbed printer embodies a significant advancement in printing technology, particularly in enhancing print quality and durability. Its innovative design allows for the printing on a wide variety of materials, including wood, glass, metal, and plastic, which broadens the scope for creative applications. This versatility is essential for businesses looking to personalize goods, as it enables them to produce high-resolution prints that maintain vibrancy and clarity over time.

Furthermore, the 6090 UV flatbed printer utilizes advanced UV curing technology, which ensures that ink dries instantly upon exposure to UV light. This rapid drying process not only enhances print speed but also results in prints that are more resistant to scratches, fading, and environmental conditions. Recent exhibitions have highlighted how this printer can cater specifically to the demands of the promotional and personalized goods sector, providing a reliable solution for businesses striving to offer unique and durable products. Its ability to deliver superior print quality while accommodating various substrates positions it as a game-changer in the printing industry.

The 6090 UV Flatbed Printer distinguishes itself from traditional printing methods through its unique capabilities and advanced technology. Unlike conventional inkjet or screen printing, the 6090 utilizes UV light to cure the ink instantly on various substrates, allowing for immediate handling and increased workflow efficiency. This technique not only enhances print quality with vibrant colors and sharp details but also supports printing on an array of materials, including wood, metal, glass, and plastic, catering to diverse industry needs.

In terms of versatility, the 6090 outshines many traditional methods that are often limited to specific substrates or require extensive preparation. Traditional printing methods may necessitate longer drying times and involve complex setup processes, impacting productivity. The 6090’s flatbed design enables printing on large objects directly, reducing waste from misalignments or fewer setup changes, making it ideal for custom projects and small runs. Overall, the 6090 UV Flatbed Printer represents a significant leap forward in printing technology, offering a modern solution that merges quality, speed, and flexibility, setting a new standard in the printing industry.

| Feature | 6090 UV Flatbed Printer | Traditional Printing Methods |

|---|---|---|

| Ink Type | UV Ink | Water-Based/Inks |

| Print Speed | High Speed (up to 50 m²/h) | Moderate Speed |

| Print Quality | High Resolution (up to 1440 dpi) | Varies (typically lower) |

| Material Compatibility | Various materials (wood, metal, glass, etc.) | Limited (mainly paper and fabric) |

| Environmental Impact | Less solvent emissions | Higher solvent emissions |

| Setup Time | Quick Setup | Longer Setup |

| Cost Efficiency | Higher Initial Investment but Lower Running Costs | Lower Initial Investment but Higher Running Costs |

The 6090 UV Flatbed Printer represents a groundbreaking advancement in printing technology, making significant strides in various design and production applications. This innovative printer allows for direct printing on a vast range of materials, including wood, glass, metal, and plastic, providing designers and manufacturers with unprecedented flexibility. Its ability to produce high-resolution images with deep, vibrant colors enhances the quality of printed products, making it particularly valuable in fields such as signage, décor, and custom packaging.

In modern design and production, the 6090 UV Flatbed Printer is paving the way for unique creative solutions. With its versatility and capacity for customization, businesses can cater to niche markets by producing intricate designs and personalized items with ease. The practicality of the 6090 also enables faster turnaround times and reduces waste, addressing the growing demand for efficiency in production processes. As the market for UV printers continues to expand, the 6090 stands out as a crucial tool for companies looking to innovate and elevate their offerings in a competitive landscape.