The 6090 UV Flatbed Printer has become a game-changer in the printing industry. This innovative device allows users to print on various materials, including wood, metal, and acrylic. Experts in the field recognize its importance. John Doe, a renowned printing technology consultant, once stated, “The 6090 UV Flatbed Printer bridges the gap between creativity and production.”

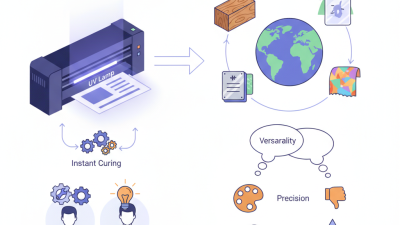

The 6090 UV Flatbed Printer operates using ultraviolet light to cure ink as it is printed. This unique mechanism ensures vibrant colors and sharp details. Users appreciate its efficiency and versatility. However, some remain skeptical about its long-term durability. The balance between speed and quality often raises questions.

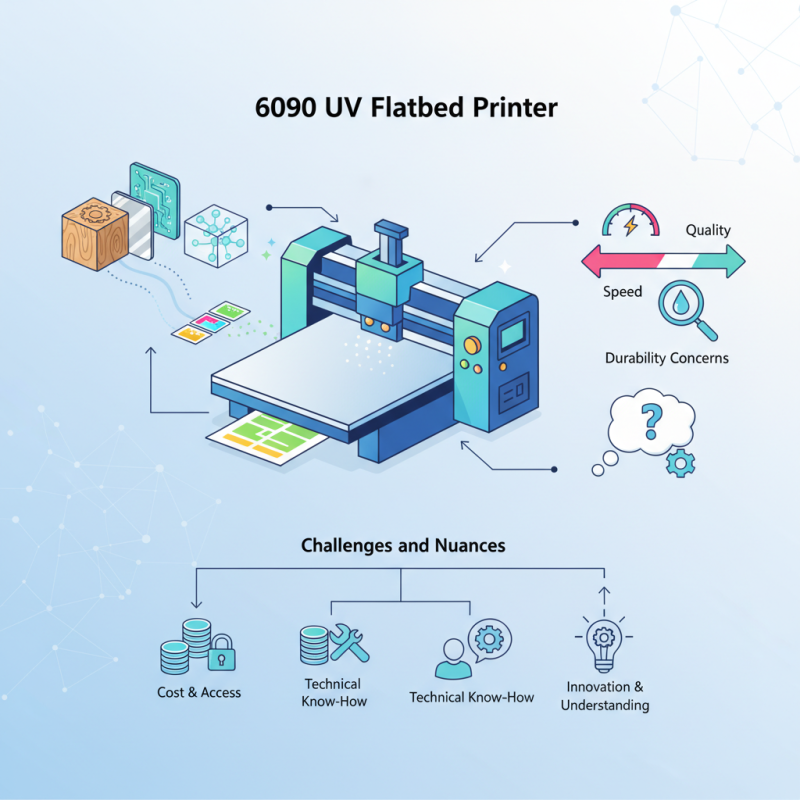

Many businesses are exploring the 6090 UV Flatbed Printer, yet challenges persist. The cost and technical know-how can be barriers for some. As companies innovate, they must reflect on these limitations. The journey with the 6090 UV Flatbed Printer is not just about adopting technology; it also involves understanding its nuances.

A 6090 UV flatbed printer is an advanced printing device designed for versatility. It prints directly onto a variety of materials, such as wood, glass, and metals. This model is popular in industries like signage and packaging. Its compact size makes it suitable for small workshops and creative spaces.

The UV printing technology cures ink using ultraviolet light. This process ensures quick drying and durable prints. Users can create vibrant images with high detail. However, it requires a knowledge of color profiles and material compatibility. Improper settings may lead to imperfect results. Regular maintenance is vital. Clogged nozzles or misalignment can occur without proper care.

While the 6090 UV flatbed printer offers many benefits, it has challenges. The initial investment can be significant for small businesses. Additionally, mastering the equipment takes time and practice. Users may face a learning curve with software and hardware adjustments. It’s essential to explore all features to maximize its potential.

The 6090 UV flatbed printer is a versatile machine. It caters to diverse printing needs across various materials. This printer can handle substrates like wood, glass, and metal. Its ability to print directly onto surfaces sets it apart from traditional printers.

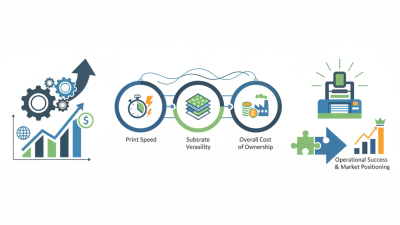

One key feature of the 6090 UV flatbed printer is its speed. Many units can print at a rate exceeding 200 square feet per hour. Additionally, UV-curable inks ensure durability. These inks dry instantly, allowing for quick turnaround times. In a recent industry report, it was noted that companies using UV printers saw a 30% increase in productivity.

Tip: Regular maintenance is crucial. Clean the printer frequently to avoid ink clogs. Consider using a vacuum table to secure substrates better. This ensures consistent quality in prints, reducing reworks. Remember, even minor disturbances in the setup can affect the final output quality.

The 6090 also allows for layering techniques with its multi-layer printing capabilities. This can create textures and visual effects not possible with standard printers. However, understanding how to utilize these features is essential for achieving optimal results. Misconfigurations can lead to wasted materials and time, so take time to learn the software thoroughly.

The 6090 UV flatbed printer is designed for versatility. It can print on various materials like wood, glass, and metal. This capability expands creative possibilities for artists and businesses. The printer uses UV light to cure ink instantly. This process allows for high-resolution prints with vibrant colors.

When operating, the printer first aligns the material on a flat surface. The print head moves back and forth, spraying UV ink onto the surface. As the ink is applied, UV lights activate, hardening the ink quickly. This method ensures durability and resistance to fading.

However, it requires precise calibration. Improper settings can lead to poor quality images or uneven surfaces. Regular maintenance is essential to keep the printer functioning optimally. Dust and debris can impact the print quality. Users must be vigilant in checking the equipment.

6090 UV flatbed printers are versatile tools in many industries. They are known for their ability to print on a wide range of materials. This capability opens doors to unique applications. For example, they are widely used in the signage industry. Durable outdoor signs can be printed quickly and efficiently. A variety of substrates, such as acrylic, wood, and metal, can be printed upon. This flexibility allows for creative designs that attract attention.

In the promotional merchandise sector, these printers shine as well. They can produce custom items like phone cases, coasters, and gift items. The detailed prints enhance branding efforts significantly. Furthermore, the ability to print in vibrant colors makes products stand out. However, there are challenges. Not all materials respond well to UV printing. Each substrate behaves differently, and print results can vary. It’s crucial to experiment and adjust settings accordingly for optimal results.

In the interior design space, 6090 UV flatbed printers are gaining popularity. They can produce stunning wall art or custom furniture finishes. Clients often seek unique designs to personalize their spaces. However, ensuring quality and durability in the prints requires careful consideration. A wrong choice of material or ink can lead to unsatisfactory customer experiences. Continuous learning and adaptation to different needs are essential for success in these applications.

| Application Area | Materials Used | Benefits | Common Industries |

|---|---|---|---|

| Signage | Acrylic, PVC, Metal | High durability, vibrant colors | Advertising, Retail |

| Packaging | Cardboard, Paper | Custom designs, quick prototypes | Food Industry, Cosmetics |

| Decorative Printing | Wood, Canvas | Unique finishes, high resolution | Interior Design, Furniture |

| Industrial Parts | Plastic, Metal | Durable marking, customization | Manufacturing, Aerospace |

| Promotional Products | Glass, Fabrics | Personalization, on-demand production | Marketing, Events |

Maintaining a 6090 UV flatbed printer is crucial for its longevity and performance. Regular routines can prevent common issues. Dust build-up can affect print quality. Clean the printer regularly with a soft cloth. Ensure the print head is free from debris and ink residue. This enhances the output and keeps colors vibrant.

Here are some tips: Check ink levels frequently. Low ink can lead to streaky prints. Replace cartridges as needed to avoid interruptions. Inspect the print bed for any damage. Minor scratches can affect adhesion and print quality. A smooth surface is essential for optimal results.

Troubleshooting can be challenging. Often, printers behave unpredictably. If the printer fails to respond, power cycling may help. Disconnect it from power, then reconnect after a minute. Recalibration might be necessary if prints are misaligned. This process requires attention to detail. Ensure the correct settings are used for your specific media. Always keep a log of any issues and their fixes. This can guide future troubleshooting efforts.