In the fast-evolving printing industry, the demand for high-quality and efficient solutions is ever-growing. The Roll To Roll UV Printer stands out as a significant player in this transformation. According to recent industry reports, the global UV printer market is expected to reach $5 billion by 2026. This growth highlights the increasing need for versatile printing technologies that can handle diverse materials.

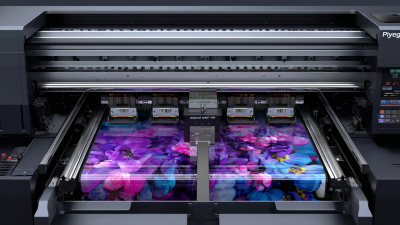

Roll To Roll UV Printers offer flexibility by accommodating a wide range of substrates. This includes vinyl, fabric, and various rigid materials. As noted by several market analysts, these printers can achieve print speeds up to 150 square meters per hour. However, the rising competitive landscape often leads to compromises in quality. Many users report that not all machines perform as advertised, raising questions about reliability and consistency.

Choosing the best Roll To Roll UV Printer for quality printing can be challenging. The selection process requires careful consideration of features and capabilities. Some models may excel in speed but fall short in detail. Critical evaluations are necessary to avoid costly mistakes. The quest for the perfect printer demands time and reflection on various options. Ultimately, a well-informed decision can lead to exceptional printing outcomes.

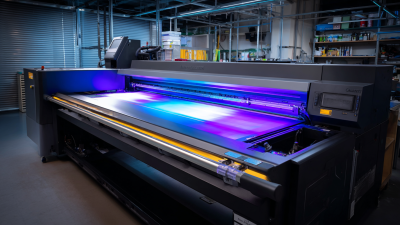

The roll-to-roll UV printing technology is evolving. In 2026, we see exciting trends shaping this industry. One noteworthy trend is the increasing focus on sustainability. Many manufacturers aim to reduce waste and improve energy efficiency. This shift towards greener practices is appealing to eco-conscious businesses. They want to make a positive impact.

Another trend is the integration of smart technology. Automation and IoT enhance efficiency. For instance, printers can self-diagnose issues. They can also adjust settings in real-time. However, this technology is not without challenges. Users may feel overwhelmed by complex interfaces. Training becomes essential to maximize benefits.

Flexibility in materials is another significant trend in 2026. Roll-to-roll printers are not just for traditional substrates anymore. Advanced models handle a variety of materials, from vinyl to textiles. This versatility opens new avenues for creativity. But it also raises questions about compatibility and performance. Print quality may vary significantly. Balancing innovation with reliability is an ongoing concern for manufacturers.

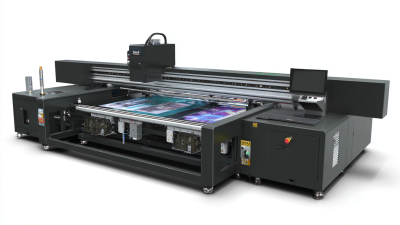

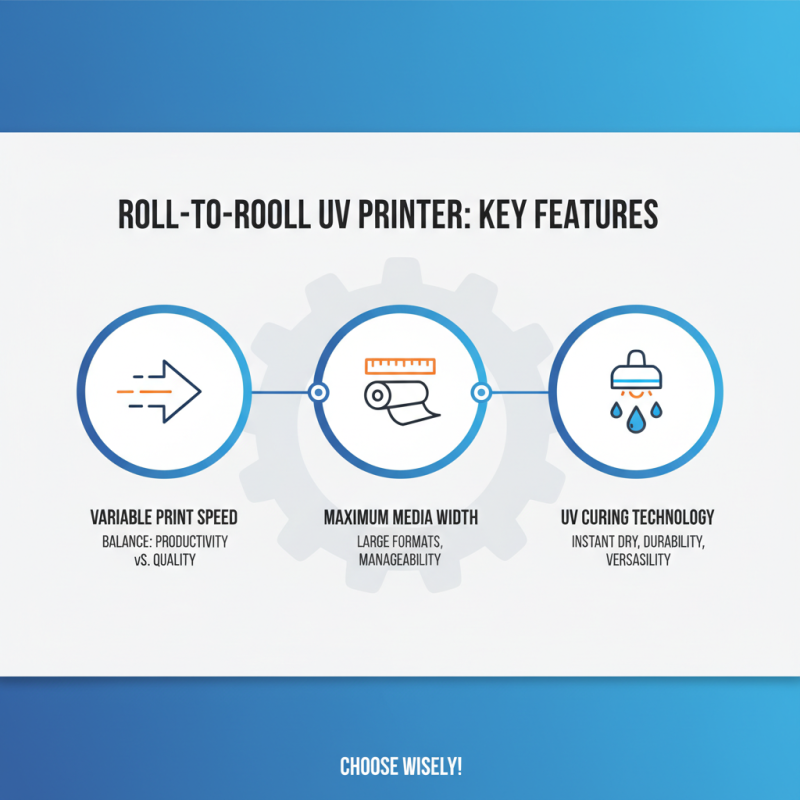

When looking for a roll to roll UV printer, several key features stand out. Variable printing speeds can be essential. Faster printers increase productivity but may compromise quality. Always consider the balance. The maximum width of the printing media is crucial too. Larger formats allow for more creative projects. However, managing wide rolls can be a challenge.

Ink types and color accuracy also play a significant role. Different inks can impact vividness and durability. It's worth experimenting with various options to find the right fit. Don’t underestimate the importance of user-friendly software. Complicated interfaces can be frustrating. Software should enhance the printing process, not hinder it.

Maintenance is often overlooked. Regular checks ensure consistent performance. But these can require time and effort. Print heads and rollers can wear out, affecting quality. A reliable warranty can mitigate these risks, yet it’s vital to understand what it covers. Remember, every feature has its pros and cons. Knowing them allows for better decision-making.

In 2026, the world of roll-to-roll UV printing is evolving. Several leading names in the industry are stepping up their game. They focus on enhancing print quality, speed, and efficiency. Advanced technology has enabled these brands to produce vibrant colors and sharp images. Print shops can now offer unique services that attract new clients.

However, the transition to the latest technology isn’t always smooth. Some printers struggle to adapt to new features. Training staff on updated equipment can be time-consuming. It’s essential to balance innovation with the need for consistent results. Customers expect top-tier prints without delays. Finding that sweet spot can be challenging.

Moreover, the market demands flexibility. Printers need to handle various materials seamlessly. This can lead to complications when switching between substrates. The potential for mistakes increases when speed is prioritized over precision. Brands are discovering that quality control remains paramount. Addressing these issues is critical for sustained success and customer satisfaction.

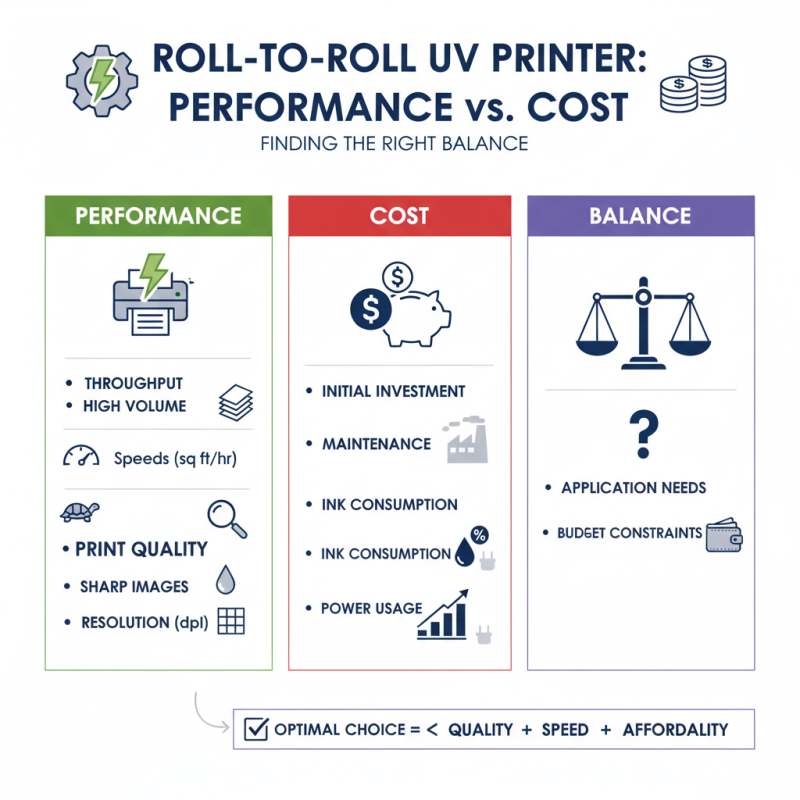

When considering the best roll-to-roll UV printer, performance and cost play significant roles. A printer’s throughput is crucial. Some models can handle high volumes but may compromise on print quality. Other printers maintain sharp images but have slower speeds. Balancing these aspects can be tricky.

The cost of ownership is another factor. Printers require maintenance and eventually replacement parts. Budgeting for these expenses is essential. High upfront costs can lead to regret if the return on investment is low. Operators often overlook hidden costs, such as ink usage and media compatibility, which can affect overall performance.

Comparing different models reveals varied strengths. Some excel in color vibrancy, while others support diverse substrates. Not all printers deliver as promised. Users should thoroughly test machines before making a purchase. This hands-on approach can uncover unexpected flaws, ensuring that the final choice aligns with practical needs.

When exploring roll-to-roll UV printers, user reviews are indispensable. They offer real-world insights into performance and capabilities. Many users praise the consistent print quality, which is essential for any print business. However, some feedback highlights issues with software compatibility. This can lead to frustration and delay.

Tip: Always check for software updates and support before purchasing. Some users found this to be a lifesaver.

Printing speed is another critical feature. Many operators report impressive speeds, but it varies based on material and design complexity. Some printers struggle with certain substrates, producing subpar results. This inconsistency can be a red flag for some businesses.

Tip: Test print on various materials before making decisions. This can save you from future disappointments.

User feedback also reveals that maintenance can be a hurdle. Regular upkeep is essential to avoid downtime. Some printers require frequent cleaning and calibration, which can be time-consuming. Users advised to allocate time for this in daily operations.

Tip: Keep a maintenance log to track issues over time. This can help in identifying patterns and improving efficiency.